Silicon carbide (SiC)zinthu zili ndi ubwino wa bandgap yotakata, matenthedwe apamwamba kwambiri, kulimba kwamunda wosweka kwambiri, komanso kuthamanga kwambiri kwa ma elekitironi oyendetsa, kupangitsa kuti ikhale yodalirika kwambiri pantchito yopanga ma semiconductor. Makhiristo amodzi a SiC nthawi zambiri amapangidwa kudzera munjira yoyendera mpweya (PVT). Njira zenizeni za njirayi zimaphatikizapo kuyika ufa wa SiC pansi pa graphite crucible ndikuyika kristalo wa mbewu ya SiC pamwamba pa crucible. The graphitecrucibleimatenthedwa ndi kutentha kwapansi kwa SiC, kuchititsa ufa wa SiC kuwola kukhala zinthu zamtundu wa nthunzi monga Si vapor, Si2C, ndi SiC2. Mothandizidwa ndi kutentha kwa axial, zinthu zosungunukazi zimatsikira pamwamba pa crucible ndikumangirira pamwamba pa kristalo wambewu ya SiC, ndikuwala kukhala makhiristo a SiC amodzi.

Pakadali pano, kukula kwa kristalo wambewu kumagwiritsidwa ntchitoSiC kukula kwa kristalo imodziiyenera kufanana ndi kristalo womwe mukufuna. Pa kukula, kristalo wa mbewu imakhazikika pa chotengera mbewu pamwamba pa crucible pogwiritsa ntchito zomatira. Komabe, njira iyi yokonzera kristalo wa mbewu imatha kubweretsa zovuta monga ma voids mu zomatira zosanjikiza chifukwa cha zinthu monga kulondola kwa malo a chotengera mbewu komanso kufananiza kwa zokutira zomatira, zomwe zimatha kubweretsa zolakwika za hexagonal. Izi zikuphatikiza kuwongolera kusalala kwa mbale ya graphite, kukulitsa kufanana kwa makulidwe a zomatira, ndikuwonjezera wosanjikiza wosinthika. Ngakhale kuyesayesa uku, pali zovuta ndi kachulukidwe wa zomatira, ndipo pali chiwopsezo cha kutsekeka kwa kristalo wa mbewu. Potsatira njira yolumikizirana ndimtandaku pepala la graphite ndikulipiringa pamwamba pa crucible, kachulukidwe ka zomatira amatha kuwongolera, ndipo kutsekeka kwa chowotcha kumatha kupewedwa.

1. Dongosolo Loyesera:

Zophika zomwe zimagwiritsidwa ntchito poyesera zimapezeka pamalonda6-inch N-mtundu wa SiC wafers. Photoresist imagwiritsidwa ntchito pogwiritsa ntchito spin coater. Kumatira kumatheka pogwiritsa ntchito ng'anjo yodzipangira yokha mbewu.

1.1 Seed Crystal Fixation Scheme:

Panopa, SiC mbewu galasi adhesion ziwembu akhoza kugawidwa m'magulu awiri: zomatira mtundu ndi kuyimitsidwa mtundu.

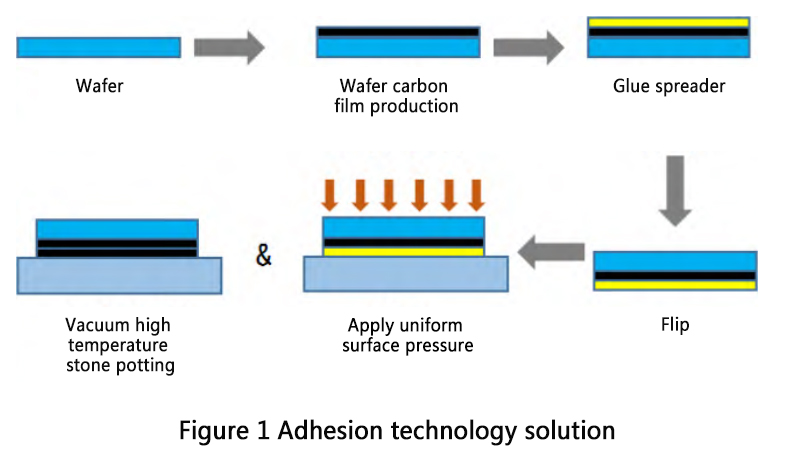

Ndondomeko yamtundu wa Adhesive (Chithunzi 1): Izi zimaphatikizapo kugwirizanitsaSiC chowotchaku mbale ya graphite yokhala ndi pepala la graphite ngati chotchinga chotchinga kuchotsa mipata pakati paSiC chowotchandi mbale ya graphite. Pakupanga kwenikweni, mphamvu yolumikizirana pakati pa pepala la graphite ndi mbale ya graphite imakhala yofooka, zomwe zimapangitsa kuti nthawi zambiri makristalo ambewu awonongeke panthawi ya kukula kwa kutentha kwambiri, zomwe zimapangitsa kuti kukula kuwonongeke.

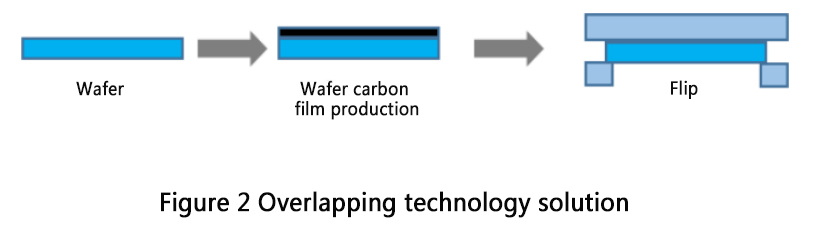

Suspension Type Scheme (Chithunzi 2): Kawirikawiri, filimu wandiweyani ya kaboni imapangidwa pamtunda womangirira wa SiC wafer pogwiritsa ntchito guluu carbonization kapena njira zokutira. TheSiC chowotchandiye amangiriridwa pakati pa mbale ziwiri za graphite ndikuyika pamwamba pa graphite crucible, kuonetsetsa bata pamene filimu ya carbon imateteza mtandawo. Komabe, kupanga filimu ya kaboni kudzera mu zokutira ndizokwera mtengo komanso sizoyenera kupanga mafakitale. Njira ya glue carbonization imatulutsa khalidwe losagwirizana ndi filimu ya carbon, zomwe zimapangitsa kuti zikhale zovuta kupeza filimu yowundana bwino ya carbon ndi yomatira mwamphamvu. Kuphatikiza apo, kukanikiza mbale za graphite kumachepetsa kukula kwabwino kwa chophatikiziracho potsekereza gawo la pamwamba pake.

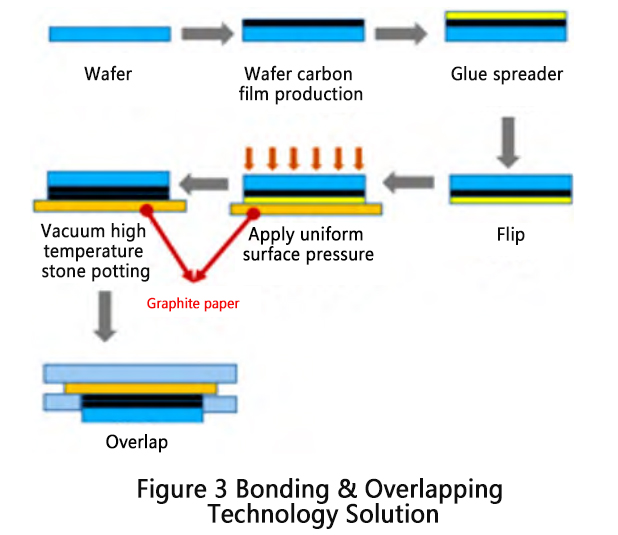

Malingana ndi ndondomeko ziwiri zomwe zili pamwambazi, ndondomeko yatsopano yomatira ndi yowonjezera ikuperekedwa (Chithunzi 3):

Kanema wa kaboni wandiweyani amapangidwa pamwamba pa chowotcha cha SiC pogwiritsa ntchito njira ya guluu carbonization, kuwonetsetsa kuti palibe kutayikira kwakukulu pakuwunikira.

Chophika cha SiC chophimbidwa ndi filimu ya kaboni chimamangiriridwa ku pepala la graphite, pomwe chomangira chimakhala mbali ya filimu ya kaboni. Zomatira zomatira ziyenera kuwoneka mofanana zakuda pansi pa kuwala.

Pepala la graphite limakutidwa ndi mbale za graphite ndikuyimitsidwa pamwamba pa graphite crucible kuti ikule.

1.2 Zomatira:

The mamasukidwe akayendedwe a photoresist kwambiri zimakhudza filimu makulidwe ofanana. Pa liwiro lomwelo lozungulira, kutsika kwa mamachulukidwe otsika kumabweretsa mafilimu owonda komanso omatira yunifolomu. Chifukwa chake, photoresist yotsika kwambiri imasankhidwa mkati mwazofunikira.

Panthawi yoyeserera, zidapezeka kuti kukhuthala kwa zomatira za carbonizing kumakhudza mphamvu yolumikizana pakati pa filimu ya kaboni ndi mkate. Kukhuthala kwakukulu kumapangitsa kuti zikhale zovuta kugwiritsa ntchito mofananamo pogwiritsira ntchito spin coater, pamene kutsika kwa viscosity kumapangitsa kuti pakhale mphamvu zomangirira zofooka, zomwe zimapangitsa kuti filimu ya kaboni iwonongeke panthawi yogwirizanitsa chifukwa cha zomatira komanso kuthamanga kwa kunja. Kupyolera mu kafukufuku woyesera, kukhuthala kwa zomatira za carbonizing kunatsimikiziridwa kukhala 100 mPa · s, ndipo kukhuthala kwa zomatira zomata kunayikidwa ku 25 mPa · s.

1.3 Vuto la ntchito:

Njira yopangira filimu ya carbon pa chowotcha cha SiC imaphatikizapo carbonizing wosanjikiza pa SiC wafer pamwamba, zomwe ziyenera kuchitidwa mu vacuum kapena malo otetezedwa ndi argon. Zotsatira zoyeserera zikuwonetsa kuti malo otetezedwa ndi argon ndiwothandiza kwambiri kuti apange filimu ya kaboni kuposa malo opumira kwambiri. Ngati malo a vacuum agwiritsidwa ntchito, mulingo wa vacuum uyenera kukhala ≤1 Pa.

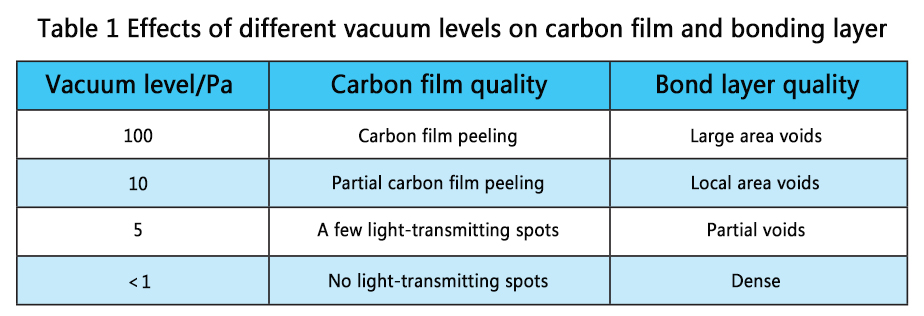

Njira yomangirira kristalo wa mbewu ya SiC imaphatikizapo kulumikiza chophika cha SiC ku mbale ya graphite / pepala la graphite. Poganizira erosive zotsatira za okosijeni pa zipangizo graphite pa kutentha kwambiri, ndondomeko ayenera kuchitidwa pansi vacuum mikhalidwe. Zotsatira za milingo yosiyanasiyana ya vacuum pa zomatira zidaphunziridwa. Zotsatira zoyesera zikuwonetsedwa mu Table 1. Zitha kuwoneka kuti pansi pa zinthu zochepa zowonongeka, mamolekyu a okosijeni mumlengalenga sachotsedwa kwathunthu, zomwe zimapangitsa kuti zikhale zosakwanira zomata. Mulingo wa vacuum ukakhala pansi pa 10 Pa, kuwonongeka kwa mamolekyu a okosijeni pazomatira kumachepetsedwa kwambiri. Pamene vacuum level ili pansi pa 1 Pa, zotsatira zowonongeka zimathetsedwa.

Nthawi yotumiza: Jun-11-2024