Pakali pano, m'badwo wachitatu wa semiconductors ukulamulidwa ndisilicon carbide. Mu mtengo wa zida zake, gawo lapansi limawerengera 47%, ndipo epitaxy imawerengera 23%. Awiriwo amawerengera pafupifupi 70%, yomwe ndi gawo lofunika kwambiri lasilicon carbidechipangizo kupanga makampani unyolo.

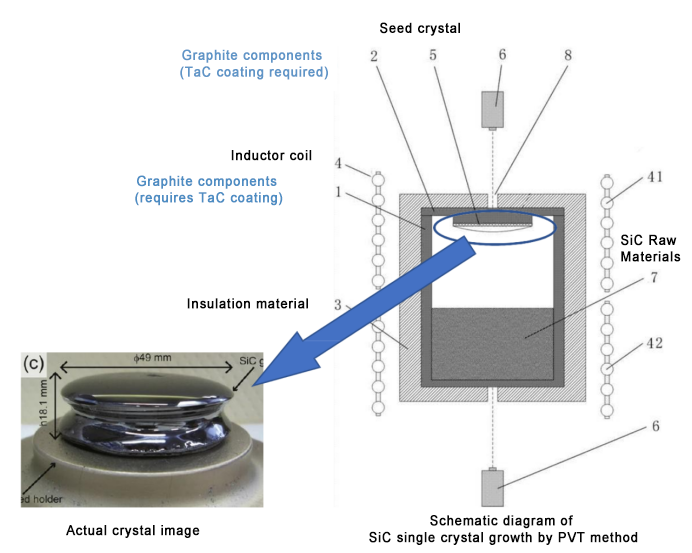

Njira yomwe imagwiritsidwa ntchito pokonzekerasilicon carbidemakhiristo amodzi ndi njira ya PVT (physical vapor transport). Mfundo yake ndi kupanga zopangira mu malo otentha kwambiri ndi kristalo wa mbewu pamalo otsika kwambiri. The zipangizo pa kutentha apamwamba kuwola ndi mwachindunji kutulutsa mpweya gawo zinthu popanda madzi gawo. Zinthu za gawo la mpweyazi zimatumizidwa ku kristalo wambewu motsogozedwa ndi kutentha kwa axial, ndipo nyukiliya ndikukula pa kristalo yambewu kuti ipange silicon carbide single crystal. Pakalipano, makampani akunja monga Cree, II-VI, SiCrystal, Dow ndi makampani apakhomo monga Tianyue Advanced, Tianke Heda, ndi Century Golden Core onse amagwiritsa ntchito njirayi.

Pali mitundu yopitilira 200 ya silicon carbide, ndipo kuwongolera kolondola kumafunika kuti pakhale mawonekedwe akristalo amodzi ofunikira (odziwika kwambiri ndi mawonekedwe a kristalo a 4H). Malinga ndi zomwe Tianyue Advanced's prospectus, zokolola za kampani ya crystal rod mu 2018-2020 ndi H1 2021 zinali 41%, 38.57%, 50.73% ndi 49.90% motsatana, ndipo zokolola za gawo lapansi zinali 72.61%, 5, 75%, 75% ndi 75%. motsatira. Zokolola zonse pano ndi 37.7% yokha. Kutengera njira yayikulu ya PVT monga chitsanzo, zokolola zotsika makamaka zimachitika chifukwa cha zovuta zotsatirazi pokonzekera gawo la SiC:

1. Kuvuta pakuwongolera kutentha kumunda: Ndodo za kristalo za SiC ziyenera kupangidwa pa kutentha kwakukulu kwa 2500 ℃, pomwe makristalo a silicon amangofunika 1500 ℃, kotero ng'anjo zapadera za kristalo zimafunikira, ndipo kutentha kwa kukula kumafunika kuyendetsedwa bwino panthawi yopanga. , zomwe ndizovuta kwambiri kuzilamulira.

2. Kuthamanga kwapang'onopang'ono: Kukula kwa zipangizo zamakono za silicon ndi 300 mm pa ola, koma silicon carbide makhiristo amodzi amatha kukula ma microns 400 pa ola, zomwe zimakhala pafupifupi 800 kusiyana.

3. Zofunikira zazikulu za magawo abwino azinthu, ndi zokolola za bokosi lakuda zimakhala zovuta kuzilamulira nthawi: Zomwe zimayambira pazitsulo za SiC zimaphatikizapo kachulukidwe ka microtube, kachulukidwe kake, resistivity, warpage, roughness pamwamba, etc. Panthawi ya kukula kwa kristalo, ndi zofunika kuwongolera molondola magawo monga silicon-carbon ratio, kukula kwa kutentha kwa gradient, kukula kwa kristalo, komanso kuthamanga kwa mpweya. Kupanda kutero, ma polymorphic inclusions amatha kuchitika, zomwe zimabweretsa makristalo osayenerera. Mu bokosi lakuda la graphite crucible, ndizosatheka kuyang'ana kukula kwa kristalo munthawi yeniyeni, ndipo kuwongolera kolondola kwambiri kwamafuta, kufananitsa zinthu, komanso kuchulukira kumafunika.

4. Zovuta pakukulitsa kristalo: Pansi pa njira yoyendera gawo la gasi, ukadaulo wokulitsa wa SiC crystal kukula ndizovuta kwambiri. Pamene kukula kwa kristalo kumawonjezeka, vuto la kukula kwake limakula kwambiri.

5. Zokolola zambiri zotsika: Zokolola zochepa zimapangidwa makamaka ndi maulalo awiri: (1) Crystal rod zokolola = semiconductor-grade crystal rod output / (semiconductor-grade crystal rod output + non-semiconductor-grade crystal rod output) × 100%; (2) Zokolola za gawo lapansi = oyenerera gawo lapansi linanena bungwe / (oyenerera gawo lapansi linanena bungwe + zotuluka zosayenerera gawo lapansi) × 100%.

Pokonzekera zapamwamba komanso zokolola zambirisilicon carbide magawo, pachimake chimafunika zipangizo zotentha zotentha kuti zithetse bwino kutentha kwapangidwe. Zida zopangira ma thermal field crucible kits zomwe zimagwiritsidwa ntchito pano ndizomwe zimagwiritsidwa ntchito kutenthetsa ndi kusungunula ufa wa kaboni ndi silicon ufa ndikutentha. Zida za graphite zimakhala ndi mphamvu zenizeni zenizeni komanso modulus yeniyeni, kukana kwa kutentha kwa kutentha ndi kukana kwa dzimbiri, koma zimakhala ndi zovuta zokhala ndi okosijeni mosavuta m'madera otentha kwambiri a okosijeni, osagonjetsedwa ndi ammonia, ndi kukana kopanda mphamvu. M'kati mwa silicon carbide single crystal kukula ndisilicon carbide epitaxial waferkupanga, n'kovuta kukwaniritsa zofuna za anthu mowonjezereka kuti agwiritse ntchito zipangizo za graphite, zomwe zimalepheretsa kukula kwake ndi ntchito zothandiza. Choncho, zokutira zotentha kwambiri monga tantalum carbide zayamba kuonekera.

2. Makhalidwe aKupaka kwa Tantalum Carbide

TaC ceramic ili ndi malo osungunuka mpaka 3880 ℃, kuuma kwakukulu (Mohs hardness 9-10), matenthedwe akulu (22W · m-1 · K-1), mphamvu yopindika yayikulu (340-400MPa), komanso kukulitsa kwakung'ono kwamafuta. coefficient (6.6 × 10−6K−1), ndipo imawonetsa kukhazikika kwabwino kwa thermochemical komanso mawonekedwe abwino kwambiri. Ili ndi kuyanjana kwamankhwala abwino komanso kuyanjana kwamakina ndi graphite ndi C / C zophatikizika. Chifukwa chake, zokutira za TaC zimagwiritsidwa ntchito kwambiri poteteza matenthedwe amlengalenga, kukula kwa galasi limodzi, zamagetsi zamagetsi, ndi zida zamankhwala.

TaC-yokutidwagraphite imakhala ndi kukana kwa dzimbiri kwamankhwala kuposa graphite yopanda kanthu kapena graphite yokhala ndi SiC, ingagwiritsidwe ntchito mosasunthika pakutentha kwambiri kwa 2600 °, ndipo sagwirizana ndi zinthu zambiri zachitsulo. Ndilo zokutira zabwino kwambiri mum'badwo wachitatu wa semiconductor single crystal kukula ndi mawonekedwe a wafer etching. Ikhoza kuwongolera kwambiri kuwongolera kutentha ndi zonyansa pokonzekera ndikukonzekeramapepala apamwamba a silicon carbidendi zokhudzanaepitaxial wafers. Ndikoyenera kwambiri kukulitsa makhiristo a GaN kapena AlN omwe ali ndi zida za MOCVD ndikukula makristasi a SiC amodzi okhala ndi zida za PVT, ndipo mtundu wa makhiristo omwe adakula amakula kwambiri.

III. Ubwino wa Tantalum Carbide Coated Devices

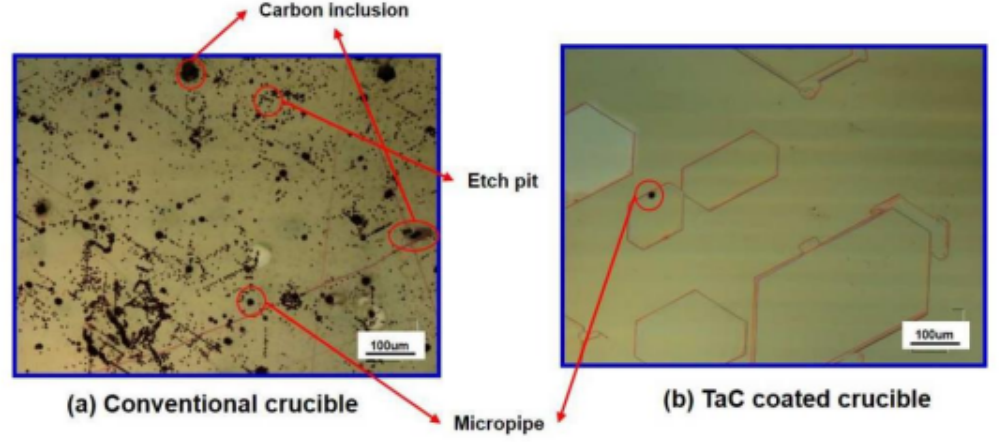

Kugwiritsa ntchito zokutira kwa Tantalum Carbide TaC kumatha kuthetsa vuto la zolakwika za kristalo ndikuwongolera kukula kwa kristalo. Ndi imodzi mwamaupangiri aukadaulo a "kukula mwachangu, kukula kolimba, ndikukula motalika". Kafukufuku wamakampani awonetsanso kuti Tantalum Carbide Coated Graphite Crucible imatha kukwaniritsa Kutentha kofananira, potero ikupereka kuwongolera kwabwino kwa SiC single crystal kukula, motero kumachepetsa kwambiri kuthekera kwa mapangidwe a polycrystalline m'mphepete mwa makhiristo a SiC. Kuphatikiza apo, Tantalum Carbide Graphite Coating ili ndi zabwino ziwiri:

(I) Kuchepetsa Zowonongeka za SiC

Pankhani yowongolera zolakwika za SiC single crystal, nthawi zambiri pamakhala njira zitatu zofunika. Kuphatikiza pa kukhathamiritsa magawo a kukula ndi zida zapamwamba kwambiri (monga SiC source powder), kugwiritsa ntchito Tantalum Carbide Coated Graphite Crucible kumathanso kupeza mtundu wabwino wa kristalo.

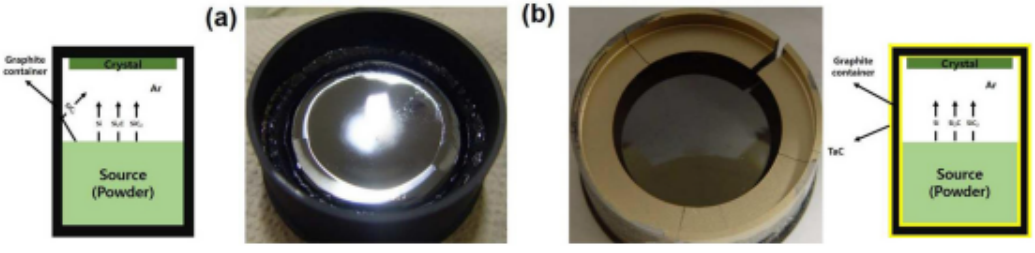

Chithunzi chojambula cha graphite crucible (a) ndi TAC coated crucible (b)

Malinga ndi kafukufuku wa University of Eastern Europe ku Korea, chodetsa chachikulu mu kukula kwa kristalo wa SiC ndi nayitrogeni, ndipo tantalum carbide yokutidwa ndi graphite crucibles imatha kuchepetsa kuphatikizika kwa nayitrogeni wa makristalo a SiC, potero kuchepetsa kubadwa kwa zolakwika monga ma micropipes ndikuwongolera kristalo. khalidwe. Kafukufuku wasonyeza kuti pansi pazikhalidwe zomwezo, zonyamulira zonyamulira za SiC zowotcha zomwe zimakula muzitsulo zamtundu wa graphite ndi TAC zokutira crucibles pafupifupi 4.5 × 1017/cm ndi 7.6 × 1015/cm, motero.

Kuyerekeza zolakwika mu makhiristo amodzi a SiC omwe amakula muzitsulo zamtundu wa graphite (a) ndi TAC zokutira crucibles (b)

(II) Kupititsa patsogolo moyo wa ma graphite crucibles

Pakalipano, mtengo wa makristasi a SiC wakhalabe wokwera, womwe mtengo wa graphite consumables umakhala pafupifupi 30%. Chinsinsi chochepetsera mtengo wa graphite consumables ndikuwonjezera moyo wake wautumiki. Malinga ndi kafukufuku wa gulu la kafukufuku waku Britain, zokutira za tantalum carbide zimatha kuwonjezera moyo wautumiki wa zigawo za graphite ndi 30-50%. Malinga ndi mawerengedwe awa, kokha m'malo tantalum carbide TACHIMATA graphite kungachepetse mtengo wa SiC makhiristo ndi 9% -15%.

4. Tantalum carbide ❖ kuyanika ndondomeko kukonzekera

Njira zokonzekera zokutira za TaC zitha kugawidwa m'magulu atatu: njira yolimba, njira yamadzimadzi ndi njira ya gasi. Njira yolimba ya gawo makamaka imaphatikizapo njira yochepetsera ndi njira yamankhwala; njira yamadzimadzi imaphatikizapo njira yosungunuka yamchere, njira ya sol-gel (Sol-gel), njira ya slurry-sintering, njira yopopera mankhwala a plasma; Njira ya gasi imaphatikizapo kuyika kwa mankhwala a vapor (CVD), kulowetsera kwa vapor wa mankhwala (CVI) ndi kuyika mpweya wakuthupi (PVD). Njira zosiyanasiyana zili ndi ubwino ndi zovuta zake. Mwa iwo, CVD ndi njira yokhwima komanso yogwiritsidwa ntchito kwambiri pokonzekera zokutira za TaC. Ndi kuwongolera kosalekeza kwa njirayi, njira zatsopano monga mawaya otentha amtundu wa vapor ndi ma ion mtengo wothandizidwa ndi mpweya wamankhwala apangidwa.

TaC ❖ kuyanika kusinthidwa carbon-based zipangizo makamaka monga graphite, mpweya CHIKWANGWANI, ndi carbon/carbon kompositi zipangizo. Njira zokonzekera zokutira za TaC pa graphite zikuphatikiza kupopera mbewu mankhwalawa kwa plasma, CVD, slurry sintering, etc.

Ubwino wa njira ya CVD: Njira ya CVD yokonzekera zokutira za TaC imachokera ku tantalum halide (TaX5) monga gwero la tantalum ndi hydrocarbon (CnHm) ngati gwero la kaboni. Nthawi zina, amawola kukhala Ta ndi C motsatana, kenako amachitirana wina ndi mnzake kuti apeze zokutira za TaC. Njira ya CVD ikhoza kuchitidwa pa kutentha kochepa, komwe kungapewe zolakwika ndi kuchepetsedwa kwa makina opangidwa chifukwa cha kukonzekera kwapamwamba kapena chithandizo cha zokutira pamlingo wina. Mapangidwe ndi mapangidwe a zokutira ndi zowongoka, ndipo zimakhala ndi ubwino wa chiyero chapamwamba, kachulukidwe kakang'ono, ndi makulidwe ofanana. Chofunika koposa, kapangidwe ndi kapangidwe ka zokutira za TaC zokonzedwa ndi CVD zitha kupangidwa ndikuwongolera mosavuta. Ndi njira yokhwima komanso yogwiritsidwa ntchito kwambiri pokonzekera zokutira zapamwamba za TaC.

Zinthu zazikuluzikulu zomwe zimagwira ntchito ndi izi:

A. Kuthamanga kwa gasi (gwero la tantalum, gasi wa hydrocarbon monga gwero la kaboni, gasi wonyamulira, gasi wa dilution Ar2, kuchepetsa gasi H2): Kusintha kwa kuchuluka kwa gasi kumakhudza kwambiri gawo la kutentha, malo oponderezedwa, ndi malo otuluka mpweya chipinda chochitira, zomwe zimapangitsa kusintha kwa kapangidwe, kapangidwe, ndi magwiridwe antchito a zokutira. Kuchulukitsa kuthamanga kwa Ar kudzachepetsa kukula kwa zokutira ndikuchepetsa kukula kwambewu, pomwe kuchuluka kwa ma molar a TaCl5, H2, ndi C3H6 kumakhudza kapangidwe kake. Chiŵerengero cha molar cha H2 ku TaCl5 ndi (15-20):1, chomwe chiri choyenera kwambiri. Chiyerekezo cha molar cha TaCl5 mpaka C3H6 chikufanana ndi 3:1. Kuchulukitsitsa kwa TaCl5 kapena C3H6 kumapangitsa kupanga Ta2C kapena kaboni waulere, zomwe zimakhudza mtundu wa mkate.

B. Kutentha kwa malo: Kukwera kwa kutentha kwa malo, kufulumira kwa kuyika, kukula kwa njere, ndi zokutira molimba. Kuphatikiza apo, kutentha ndi liwiro la kuwonongeka kwa hydrocarbon kukhala C ndi TaCl5 kuwola kukhala Ta ndizosiyana, ndipo Ta ndi C amatha kupanga Ta2C. Kutentha kumakhudza kwambiri zokutira za TaC zosinthidwa za kaboni. Pamene kutentha kwa malo kumawonjezeka, kuchuluka kwa chiwerengero kumawonjezeka, kukula kwa tinthu kumawonjezeka, ndipo mawonekedwe a tinthu amasintha kuchokera ku spherical kupita ku polyhedral. Kuonjezera apo, kutentha kwa kutentha kumakwera, kuwonongeka kwa TaCl5 mofulumira, kuchepa kwa C kudzakhala kochepa, kupanikizika kwakukulu mu zokutira, ndipo ming'alu imapangidwa mosavuta. Komabe, kutentha kwapang'onopang'ono kumapangitsa kutsika kwamatekinoloje, nthawi yayitali yoyika, komanso kutsika mtengo kwazinthu zopangira.

C. Mafunsidwe kuthamanga: mafunsidwe kuthamanga kwambiri zokhudzana ndi ufulu mphamvu ya zinthu padziko ndipo zingakhudze mpweya okhala nthawi mu anachita chipinda, potero zimakhudza nucleation liwiro ndi tinthu kukula ❖ kuyanika. Pamene kuthamanga kwa mafunsidwe kumawonjezeka, nthawi yokhala ndi mpweya imakhala yotalikirapo, ma reactants amakhala ndi nthawi yochulukirapo kuti akumane ndi zochitika za nucleation, kuchuluka kwa zomwe zimachitika, tinthu tating'onoting'ono timakhala tokulirapo, ndipo ❖ kuyanika kumakhala kokulirapo; Tikawonetsetsa, monga mafunsidwe kuthamanga amachepetsa, zimene mpweya okhala nthawi yochepa, zimene mlingo kubweza pansi, ndi particles kukhala ang'onoang'ono, ndi ❖ kuyanika ndi woonda, koma mafunsidwe kuthamanga ali ndi zotsatira zochepa pa kapangidwe galasi ndi zikuchokera ❖ kuyanika.

V. Chitukuko cha zokutira tantalum carbide

Thermal coefficient of TaC (6.6 × 10−6K-1) ndi yosiyana pang'ono ndi ya carbon-based materials monga graphite, carbon fiber, ndi C/C composite materials, zomwe zimapangitsa kuti zokutira za TaC za gawo limodzi zizikhala zong'ambika komanso kugwa. Pofuna kupititsa patsogolo kukana kwa ma ablation ndi oxidation, kukhazikika kwamakina otenthetsera, komanso kukana kwamphamvu kwamadzimadzi kwamankhwala a TaC, ofufuza achita kafukufuku wamakina opaka utoto monga makina okutira ophatikizika, makina opaka olimba owonjezera, ndi gradient. ❖ kuyanika machitidwe.

Chophimba chophatikizika ndi kutseka ming'alu ya chophimba chimodzi. Nthawi zambiri, zokutira zina zimalowetsedwa pamwamba kapena mkati mwa TaC kuti apange makina opaka; olimba njira yothetsera ❖ kuyanika dongosolo HfC, ZrC, etc. ndi chimodzimodzi nkhope-centered kiyubiki dongosolo TaC, ndi carbides awiri akhoza sungunuka mopanda malire wina ndi mzake kupanga cholimba yankho dongosolo. Chophimba cha Hf (Ta) C sichimang'ambika ndipo chimamatira bwino kuzinthu zophatikizika za C / C. Chophimbacho chimakhala ndi ntchito yabwino kwambiri yotsutsana ndi ablation; ❖ kuyanika kwa gradient system gradient kumatanthawuza kuyika kwa chigawo chophikira motsatira makulidwe ake. Kapangidwe kameneka kamatha kuchepetsa kupsinjika kwamkati, kukonza kusagwirizana kwa ma coefficients okulitsa kutentha, ndikupewa ming'alu.

(II) Tantalum carbide ❖ kuyanika zipangizo zipangizo

Malinga ndi ziwerengero ndi zoneneratu za QYR (Hengzhou Bozhi), msika wapadziko lonse wa tantalum carbide coating coating mu 2021 udafika US $ 1.5986 miliyoni (kupatula zida zodzipangira zokha za Cree komanso zodzipangira yekha tantalum carbide), ndipo ikadali koyambirira. magawo a chitukuko cha mafakitale.

1. Mphete zowonjezera kristalo ndi crucibles zomwe zimafunikira kuti kristalo ikule: Kutengera ng'anjo zokulirapo za kristalo 200 pabizinesi iliyonse, gawo la msika la zida zokutira za TaC zomwe zimafunidwa ndi makampani 30 okulitsa makristalo ndi pafupifupi 4.7 biliyoni ya yuan.

2. Mathireyi a TaC: Thireyi iliyonse imatha kunyamula zopyapyala zitatu, thireyi iliyonse itha kugwiritsidwa ntchito kwa mwezi umodzi, ndipo thireyi imodzi imadyedwa pamipando 100 iliyonse. 3 miliyoni zophika zimafuna ma tray 30,000 a TaC, tray iliyonse imakhala pafupifupi 20,000 zidutswa, ndipo pafupifupi 600 miliyoni amafunikira chaka chilichonse.

3. Zochitika zina zochepetsera mpweya. Monga mkulu-kutentha ng'anjo akalowa, CVD nozzle, mapaipi ng'anjo, etc., pafupifupi 100 miliyoni.

Nthawi yotumiza: Jul-02-2024