Kukonzekera kwa MEMS - Kumanga: Kugwiritsa Ntchito ndi Kuchita mu Semiconductor Industry, Semicera Customized Service

M'makampani opanga ma microelectronics ndi semiconductor, teknoloji ya MEMS (micro-electromechanical systems) yakhala imodzi mwamakina apamwamba omwe amayendetsa zipangizo zamakono komanso zogwira ntchito kwambiri. Ndi kupita patsogolo kwa sayansi ndi luso, luso MEMS wakhala chimagwiritsidwa ntchito masensa, actuators, zipangizo kuwala, zipangizo zachipatala, zamagetsi galimoto ndi madera ena, ndipo pang'onopang'ono wakhala mbali yofunika kwambiri zamakono zamakono. M'madera awa, njira yolumikizirana (Bonding), monga gawo lofunikira pakukonza kwa MEMS, imagwira ntchito yofunika kwambiri pakuchita komanso kudalirika kwa chipangizocho.

Kulumikizana ndi ukadaulo womwe umaphatikiza mwamphamvu zida ziwiri kapena zingapo pogwiritsa ntchito njira zakuthupi kapena zamankhwala. Nthawi zambiri, zigawo zazinthu zosiyanasiyana zimafunikira kulumikizidwa ndikulumikizana ndi zida za MEMS kuti zikwaniritse kukhulupirika kwadongosolo komanso kuzindikira magwiridwe antchito. Popanga zida za MEMS, kugwirizanitsa sikungolumikizana kokha, komanso kumakhudza mwachindunji kukhazikika kwa kutentha, mphamvu zamakina, ntchito zamagetsi ndi zina za chipangizocho.

Pakukonza kolondola kwambiri kwa MEMS, ukadaulo wolumikizira uyenera kuwonetsetsa kulumikizana kwapakati pakati pa zida ndikupewa zolakwika zilizonse zomwe zimakhudza magwiridwe antchito a chipangizocho. Chifukwa chake, kuwongolera kolondola kwa njira yolumikizirana komanso zida zomangira zapamwamba ndizofunikira kwambiri kuti chomalizacho chikwaniritse miyezo yamakampani.

Kugwiritsa ntchito mgwirizano wa MEMS mumakampani a semiconductor

M'makampani opanga ma semiconductor, ukadaulo wa MEMS umagwiritsidwa ntchito kwambiri popanga zida zazing'ono monga masensa, ma accelerometers, masensa akukakamiza, ndi ma gyroscopes. Pakuchulukirachulukira kwa zinthu zazing'ono, zophatikizika, komanso zanzeru, kulondola komanso magwiridwe antchito a zida za MEMS zikuchulukiranso. Muzochita izi, ukadaulo wolumikizira umagwiritsidwa ntchito kulumikiza zida zosiyanasiyana monga zowotcha za silicon, magalasi, zitsulo, ndi ma polima kuti akwaniritse ntchito zabwino komanso zokhazikika.

1. Makanema othamanga ndi ma accelerometers

M'minda yamagalimoto, zakuthambo, zamagetsi ogula, ndi zina zambiri, makina amphamvu a MEMS ndi ma accelerometers amagwiritsidwa ntchito kwambiri poyezera ndi kuwongolera machitidwe. Njira yolumikizira imagwiritsidwa ntchito kulumikiza tchipisi ta silicon ndi zinthu za sensor kuti zitsimikizire kukhudzika kwakukulu komanso kulondola. Masensawa ayenera kupirira mikhalidwe yoopsa ya chilengedwe, ndipo njira zomangirira zapamwamba zingathe kulepheretsa zipangizo kuti zisawonongeke kapena zisagwire bwino chifukwa cha kusintha kwa kutentha.

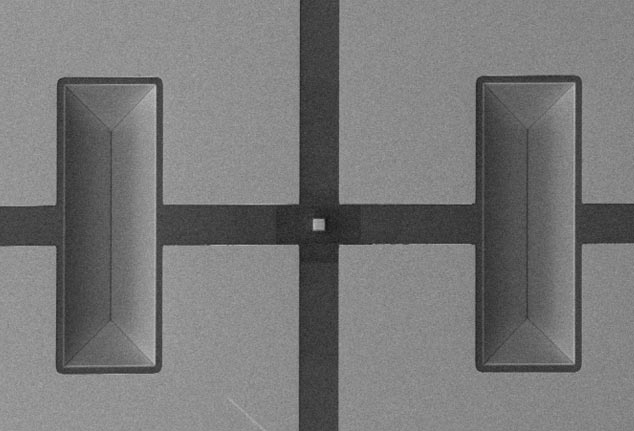

2. Zida zazing'ono zowoneka bwino ndi masiwichi a MEMS

M'munda wamalumikizidwe owoneka bwino ndi zida za laser, zida za MEMS zowunikira komanso zosinthira zowonera zimagwira ntchito yofunika. Tekinoloje yolumikizira imagwiritsidwa ntchito kuti ikwaniritse kulumikizana kolondola pakati pa zida za silicon zochokera ku MEMS ndi zida monga ulusi wamawonekedwe ndi magalasi kuti zitsimikizire kukhazikika komanso kukhazikika kwa kufalitsa ma siginecha. Makamaka pamapulogalamu okhala ndi ma frequency apamwamba, bandwidth yotakata komanso kutumizirana mtunda wautali, ukadaulo wolumikizana kwambiri ndi wofunikira.

3. MEMS gyroscopes ndi masensa inertial

Ma gyroscopes a MEMS ndi masensa a inertial amagwiritsidwa ntchito kwambiri poyenda bwino komanso kuyikika m'mafakitale apamwamba monga kuyendetsa galimoto, maloboti, ndi zakuthambo. Njira zomangiriza zolondola kwambiri zimatha kutsimikizira kudalirika kwa zida ndikupewa kuwonongeka kwa magwiridwe antchito kapena kulephera pakugwira ntchito kwanthawi yayitali kapena kuthamangitsa kwambiri.

Zofunikira zazikulu zogwirira ntchito zaukadaulo wamabizinesi pakukonza kwa MEMS

Mu MEMS processing, khalidwe la ndondomeko yomangira imatsimikizira mwachindunji ntchito, moyo ndi kukhazikika kwa chipangizocho. Pofuna kuwonetsetsa kuti zida za MEMS zitha kugwira ntchito modalirika kwa nthawi yayitali pamachitidwe osiyanasiyana ogwiritsira ntchito, ukadaulo wolumikizana uyenera kukhala ndi izi:

1. Kukhazikika kwa kutentha kwakukulu

Malo ambiri ogwiritsira ntchito m'makampani opanga ma semiconductor amakhala ndi kutentha kwakukulu, makamaka m'magalimoto, malo opangira ndege, ndi zina zotero. Kukhazikika kwamafuta azinthu zomangira ndikofunikira ndipo kumatha kupirira kusintha kwa kutentha popanda kuwonongeka kapena kulephera.

2. Kukana kuvala kwakukulu

Zipangizo za MEMS nthawi zambiri zimakhala ndi makina ang'onoang'ono, ndipo kukangana kwanthawi yayitali ndi kusuntha kungayambitse kuwonongeka kwa magawo olumikizirana. Zinthu zomangira zimayenera kukhala ndi kukana kovala bwino kuti zitsimikizire kukhazikika komanso mphamvu ya chipangizocho pakagwiritsidwe ntchito kwanthawi yayitali.

3. Chiyero chachikulu

Makampani a semiconductor ali ndi zofunika kwambiri pa kuyera kwa zinthu. Zoyipa zilizonse zazing'ono zimatha kuyambitsa kulephera kwa chipangizocho kapena kuwonongeka kwa magwiridwe antchito. Choncho, zipangizo zomwe zimagwiritsidwa ntchito pogwirizanitsa ziyenera kukhala zoyera kwambiri kuti zitsimikizire kuti chipangizocho sichikukhudzidwa ndi kuipitsidwa kwakunja panthawi yogwira ntchito.

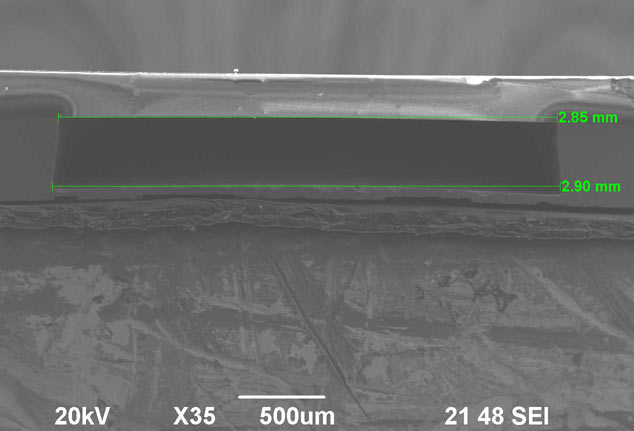

4. Kulondola kolumikizana kolondola

Zida za MEMS nthawi zambiri zimafuna kulondola kwa ma micron-level kapena ngakhale nanometer-level processing. Njira yolumikizirana iyenera kuonetsetsa kuti docking yolondola ya gawo lililonse lazinthu kuti zitsimikizire kuti ntchito ndi magwiridwe antchito a chipangizocho sizikhudzidwa.

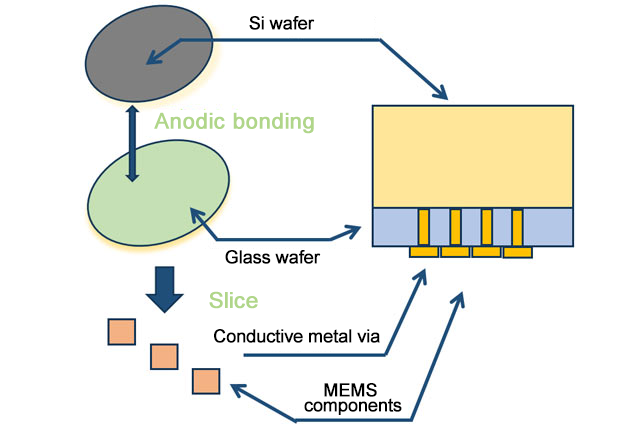

Kugwirizana kwa anodic

Kugwirizana kwa Anodic:

● Kugwirizana pakati pa silicon wafers ndi galasi, zitsulo ndi galasi, semiconductor ndi aloyi, ndi semiconductor ndi galasi.

Kugwirizana kwa Eutectoid:

● Imagwira ntchito kuzinthu monga PbSn, AuSn, CuSn, ndi AuSi

Glue kugwirizana:

● Gwiritsani ntchito guluu wapadera womangira, woyenera kugwirizana ndi magulu apadera monga AZ4620 ndi SU8

● Imagwira pa 4-inch ndi 6-inchi

Semicera Custom Bonding Service

Monga wotsogola wotsogola m'makampani opanga mayankho a MEMS, Semicera yadzipereka kupatsa makasitomala njira zomangira zolondola kwambiri, zokhazikika kwambiri. Tekinoloje yathu yolumikizira imatha kugwiritsidwa ntchito kwambiri polumikizana ndi zinthu zosiyanasiyana, kuphatikiza silicon, galasi, zitsulo, zoumba, ndi zina zambiri, kupereka njira zatsopano zothetsera ntchito zapamwamba m'minda ya semiconductor ndi MEMS.

Semicera ili ndi zida zopangira zapamwamba komanso magulu aukadaulo, ndipo imatha kupereka njira zolumikizirana makonda malinga ndi zosowa za makasitomala. Kaya ndi kugwirizana kodalirika pansi pa kutentha kwakukulu ndi malo othamanga kwambiri, kapena kugwirizanitsa zenizeni za micro-chipangizo, Semicera ikhoza kukwaniritsa zofunikira zosiyanasiyana zovuta kuti zitsimikizire kuti chinthu chilichonse chikhoza kukwaniritsa miyezo yapamwamba kwambiri.

Utumiki wathu womangirira wokhazikika sikuti umangokhala ndi njira zomangirira wamba, komanso umaphatikizanso kulumikiza zitsulo, kuphatikizika kwamafuta, kulumikiza zomatira ndi njira zina, zomwe zingapereke chithandizo chaukadaulo chaukadaulo pazinthu zosiyanasiyana, kapangidwe kake ndi zofunikira zogwiritsira ntchito. Kuphatikiza apo, Semicera imatha kupatsanso makasitomala ntchito zonse kuyambira pakupanga mawonekedwe mpaka kupanga zochuluka kuti zitsimikizire kuti zofunikira zonse zamakasitomala zitha kukwaniritsidwa molondola.