Ubwino wake

Kutentha kwakukulu kwa okosijeni kukana

Zabwino kwambiri Corrosion resistance

Good Abrasion resistance

High coefficient of conductivity kutentha

Kudzipangira mafuta, kachulukidwe kakang'ono

Kuuma kwakukulu

Mapangidwe mwamakonda.

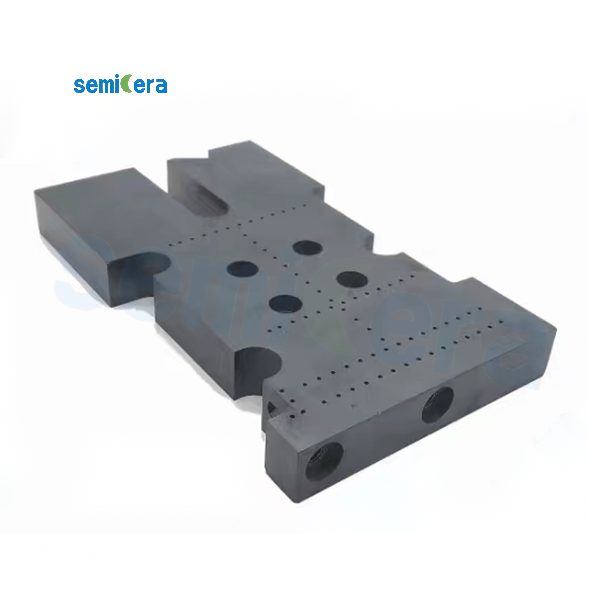

Mapulogalamu

-Munda wosamva kuvala: ming'alu, mbale, mphuno ya mchenga, mbiya yamkuntho, mbiya yopera, etc ...

-High Temperature Field: siC Slab, Kuzimitsa Furnace Tube, Radiant Tube, crucible, Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boti, Kiln Car Structure, Setter, etc.

-Silicon Carbide Semiconductor: SiC wafer bwato, sic chuck, sic paddle, sic cassette, sic diffusion chubu, wafer foloko, mbale kuyamwa, kanjira, etc.

-Silicon Carbide Seal Field: mitundu yonse ya mphete zosindikizira, kubala, tchire, etc.

-Munda wa Photovoltaic: Cantilever Paddle, Mgolo Wopera, Silicon Carbide Roller, etc.

- Lithium Battery Field

Mawonekedwe a SiC

| Katundu | Mtengo | Njira |

| Kuchulukana | 3.21g/cc | Sink-float ndi dimension |

| Kutentha kwenikweni | 0.66 J/g °K | Kuwala kwa laser pulsed |

| Flexural mphamvu | 450 MPa 560 MPa | 4 point bend, RT4 point bend, 1300° |

| Kulimba kwa fracture | 2.94 MPa m1/2 | Microindentation |

| Kuuma | 2800 | Vicker, 500g katundu |

| Elastic ModulusYoung's Modulus | 450 GPA430 GPA | 4 pt bend, RT4 pt bend, 1300 °C |

| Kukula kwambewu | 2 - 10 μm | Mtengo wa SEM |

Thermal Properties of SiC

| Thermal Conductivity | 250 W/m °K | Njira ya laser flash, RT |

| Kukula kwa Thermal (CTE) | 4.5 x 10-6 °K | Kutentha kwachipinda mpaka 950 ° C, silika dilatometer |

Magawo aukadaulo

| Kanthu | Chigawo | Deta | ||||

| RBSiC(SiSiC) | NBSiC | SSiC | Mtengo wa RSiC | OSiC | ||

| Zinthu za SiC | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Zaulere za silicon | % | 15 | 0 | 0 | 0 | 0 |

| Kutentha kwakukulu kwa utumiki | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Kuchulukana | g/cm3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Open porosity | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Mphamvu yopindika 20 ℃ | Mpa | 250 | 160 | 380 | 100 | / |

| Mphamvu yopindika 1200 ℃ | Mpa | 280 | 180 | 400 | 120 | / |

| Modulus ya elasticity 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modulus ya elasticity 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Coefficient ya kukula kwa kutentha | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

The CVD silicon carbide ❖ kuyanika pa kunja kwa recrystallized pakachitsulo carbide ceramic mankhwala akhoza kufika chiyero choposa 99.9999% kukwaniritsa zosowa za makasitomala mu makampani semiconductor.