Chiyambi cha CVD TaC Coating:

CVD TaC Coating ndi ukadaulo womwe umagwiritsa ntchito vapor wamankhwala kuyika zokutira tantalum carbide (TaC) pamwamba pa gawo lapansi. Tantalum carbide ndi zida za ceramic zogwira ntchito kwambiri zomwe zimakhala ndi makina abwino kwambiri komanso mankhwala. Njira ya CVD imapanga filimu yofananira ya TaC pamwamba pa gawo lapansi pogwiritsa ntchito mpweya.

Mbali zazikulu:

Wabwino kuuma ndi kuvala kukana: Tantalum carbide imakhala ndi kuuma kwambiri, ndipo Kupaka kwa CVD TaC kumatha kusintha kwambiri kukana kwa gawo lapansi. Izi zimapangitsa kuti zokutira zikhale zabwino kwambiri pazogwiritsidwa ntchito m'malo ovala kwambiri, monga zida zodulira ndi nkhungu.

Kutentha Kwambiri Kukhazikika: Zovala za TaC zimateteza ng'anjo yovuta kwambiri ndi zigawo za reactor pa kutentha mpaka 2200 ° C, kusonyeza kukhazikika kwabwino. Imasunga kukhazikika kwa mankhwala ndi makina pansi pa kutentha kwakukulu, ndikupangitsa kuti ikhale yoyenera kutentha kwapamwamba komanso ntchito m'madera otentha kwambiri.

Kukhazikika kwabwino kwamankhwala: Tantalum carbide ali ndi dzimbiri kukana kwambiri zidulo ndi alkalis, ndi CVD TaC ❖ kuyanika angathe kuteteza kuwonongeka kwa gawo lapansi m'madera dzimbiri.

Malo osungunuka kwambiri: Tantalum carbide imakhala ndi malo osungunuka kwambiri (pafupifupi 3880 ° C), kulola CVD TaC Coating kuti igwiritsidwe ntchito pa kutentha kwakukulu popanda kusungunuka kapena kunyozeka.

Wabwino matenthedwe madutsidwe: Kupaka kwa TaC kumakhala ndi matenthedwe apamwamba kwambiri, omwe amathandiza kuti azitha kutentha kwambiri m'njira zotentha kwambiri komanso kupewa kutenthedwa m'deralo.

Ntchito zomwe zingatheke:

• Gallium Nitride (GaN) ndi Silicon Carbide epitaxial CVD reactor components kuphatikizapo zonyamulira zopyapyala, mbale za satellite, mitu ya shawa, siling'ono, ndi zoyatsira

• Silicon carbide, gallium nitride ndi aluminium nitride (AlN) crystal kukula zigawo kuphatikizapo crucibles, zosungira mbewu, mphete zolondolera ndi zosefera

• Zigawo za mafakitale kuphatikizapo kukana kutentha zinthu, jekeseni nozzles, masking mphete ndi brazing jigs

Zogwiritsa ntchito:

• Kutentha kokhazikika pamwamba pa 2000 ° C, kulola kugwira ntchito pa kutentha kwambiri

• Kugonjetsedwa ndi haidrojeni (Hz), ammonia (NH3), monosilane (SiH4) ndi silicon (Si), kupereka chitetezo m'malo ovuta kwambiri a mankhwala.

• Kutentha kwake kwa kutentha kumapangitsa kuti ntchito ziziyenda mofulumira

• Graphite ali ndi adhesion amphamvu, kuonetsetsa moyo wautali utumiki ndipo palibe ❖ kuyanika delamination.

• Kuyeretsa kwambiri kuti muchotse zonyansa zosafunika kapena zowonongeka

• Kuphimba kumamatira kuti zisaloledwe zolimba

Mfundo zaukadaulo:

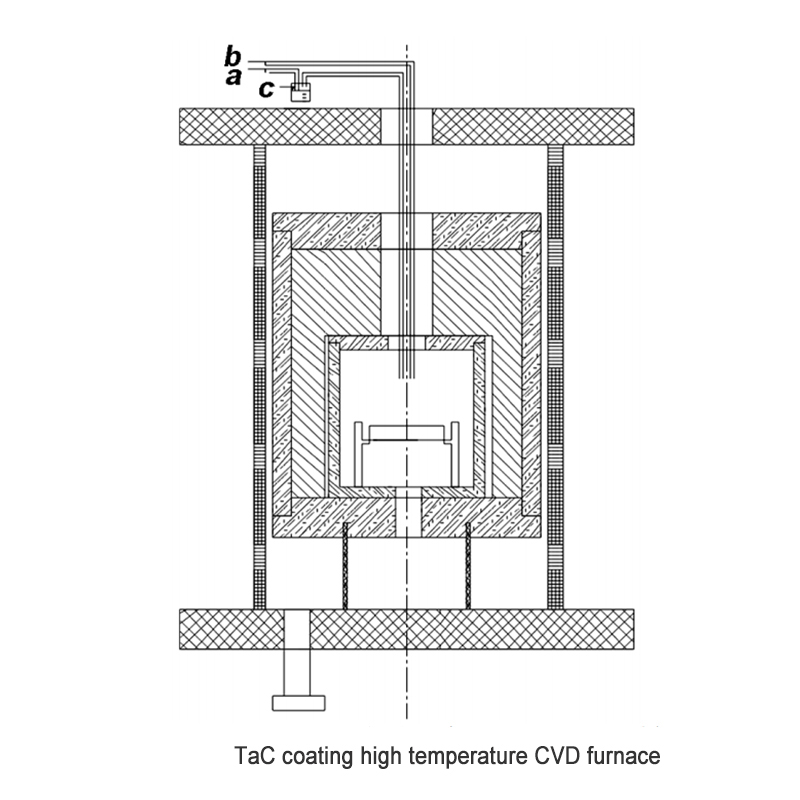

Kukonzekera zokutira wandiweyani tantalum carbide ndi CVD:

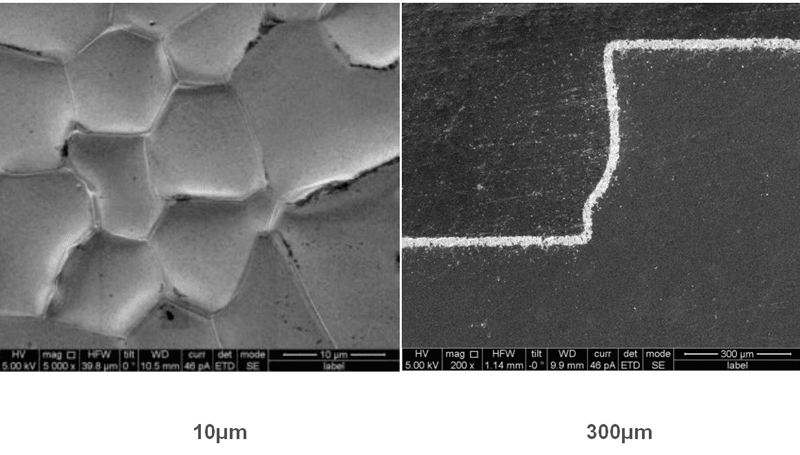

TAC ❖ kuyanika ndi crystallinity mkulu ndi ofanana kwambiri:

CVD TAC COATING Technical Parameters_Semicera:

| Zakuthupi za zokutira za TaC | |

| Kuchulukana | 14.3 (g/cm³) |

| Kukhazikika Kwambiri | 8x10 pa15/cm |

| Kutulutsa kwapadera | 0.3 |

| Kuwonjezela kwamafuta kokwana | 6.3 10-6/K |

| Kulimba (HK) | 2000 HK |

| Kukana Kwambiri | 4.5 ohm-cm |

| Kukaniza | 1x10 pa-5uwu *cm |

| Kukhazikika kwamafuta | <2500℃ |

| Kuyenda | 237cm pa2/Vs |

| Kusintha kwa kukula kwa graphite | -10 ~ 20um |

| Kupaka makulidwe | ≥20um mtengo wamba (35um + 10um) |

Zomwe zili pamwambazi ndizodziwika bwino.