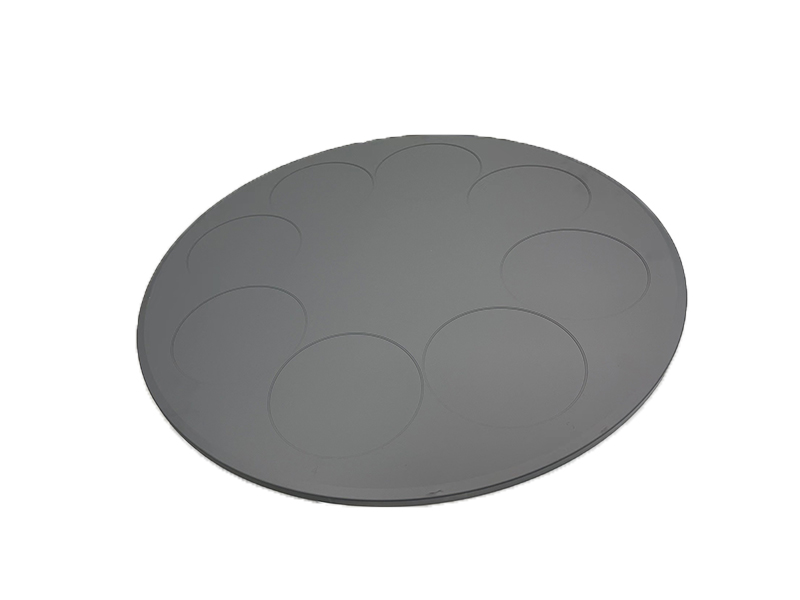

The Solid Silicon Carbide(SiC) Etching Rings yoperekedwa ndi Semicera imapangidwa ndi njira ya Chemical Vapor Deposition (CVD) ndipo ndi zotsatira zabwino kwambiri pakugwiritsa ntchito njira zolondola. Izi Solid Silicon Carbide(SiC) Etching Rings zimadziwika chifukwa cha kuuma kwawo kwakukulu, kukhazikika kwamafuta komanso kukana dzimbiri, ndipo zinthu zapamwamba kwambiri zimatsimikiziridwa ndi kaphatikizidwe ka CVD.

Zopangidwira ma etching process, Solid Silicon Carbide(SiC) Etching Rings' mawonekedwe olimba komanso zida zapadera zimagwira ntchito yofunika kwambiri pakukwaniritsa bwino komanso kudalirika. Mosiyana ndi zida zachikhalidwe, gawo lolimba la SiC lili ndi kulimba kosayerekezeka komanso kukana kuvala, zomwe zimapangitsa kuti ikhale yofunika kwambiri m'mafakitale omwe amafunikira kulondola komanso moyo wautali.

Zipangizo Zathu Zolimba za Silicon Carbide(SiC) Etching zimapangidwa mwatsatanetsatane komanso zimayendetsedwa bwino kuti zitsimikizire kuti zimagwira ntchito bwino komanso zodalirika. Kaya mukupanga ma semiconductor kapena magawo ena ofananira, awa Solid Silicon Carbide(SiC) Etching Rings amatha kupereka magwiridwe antchito okhazikika komanso zotsatira zabwino kwambiri zokopa.

Ngati muli ndi chidwi ndi Solid Silicon Carbide(SiC) Etching Ring yathu, chonde titumizireni. Gulu lathu likupatsirani zambiri zamalonda ndi chithandizo chaukadaulo chaukadaulo kuti mukwaniritse zosowa zanu. Tikuyembekezera kukhazikitsa mgwirizano wanthawi yayitali ndi inu komanso kulimbikitsa limodzi chitukuko chamakampani.

✓Zapamwamba kwambiri pamsika waku China

✓Utumiki wabwino nthawi zonse kwa inu, maola 7*24

✓Tsiku lachidule la kutumiza

✓MOQ yaying'ono yalandiridwa ndikuvomerezedwa

✓Ntchito zamwambo

Epitaxy Growth Susceptor

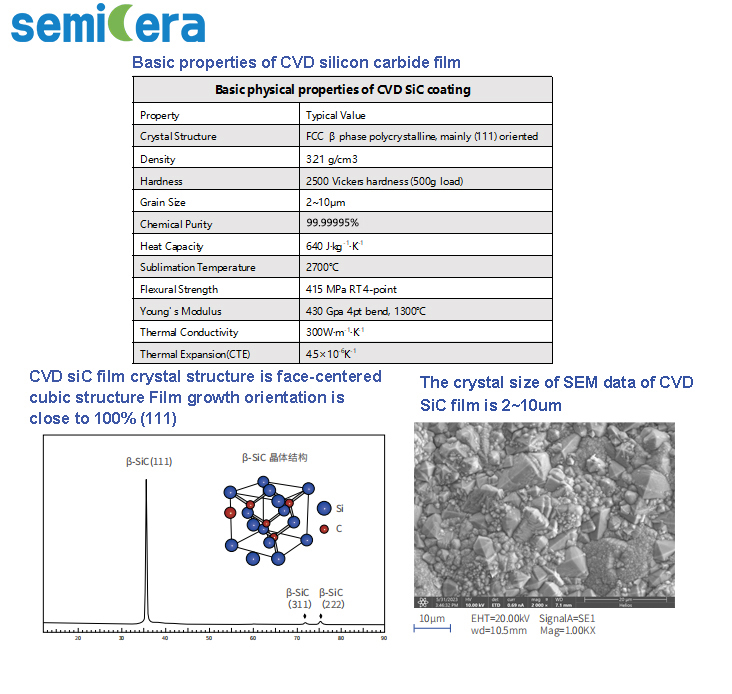

Zophika za silicon / silicon carbide ziyenera kudutsa njira zingapo kuti zigwiritsidwe ntchito pazida zamagetsi. Njira yofunikira ndi silicon / sic epitaxy, momwe zowotcha za silicon / sic zimanyamulidwa pamtunda wa graphite. Ubwino wapadera wa Semicera's silicon carbide-coated graphite base umaphatikizapo kuyera kwambiri, zokutira yunifolomu, komanso moyo wautali wautumiki. Amakhalanso ndi kukana kwamphamvu kwamankhwala komanso kukhazikika kwamafuta.

LED Chip Production

Pa zokutira zambiri za MOCVD riyakitala, mapulaneti m'munsi kapena chonyamulira amasuntha gawo lapansi lopyapyala. Kuchita kwa zinthu zoyambira kumakhudza kwambiri mtundu wa zokutira, zomwe zimakhudzanso kuchuluka kwa zidutswa za chip. Semicera's silicon carbide-yokutidwa ndi maziko amawonjezera kupanga kwamafuta apamwamba a LED ndikuchepetsa kupatuka kwa mawonekedwe. Timaperekanso zigawo zina za graphite kwa ma reactor onse a MOCVD omwe akugwiritsidwa ntchito pano. Titha kuvala pafupifupi chigawo chilichonse ndi zokutira za silicon carbide, ngakhale m'mimba mwake mpaka 1.5M, titha kuvala ndi silicon carbide.

Semiconductor Field, Oxidation Diffusion process, ndi zina.

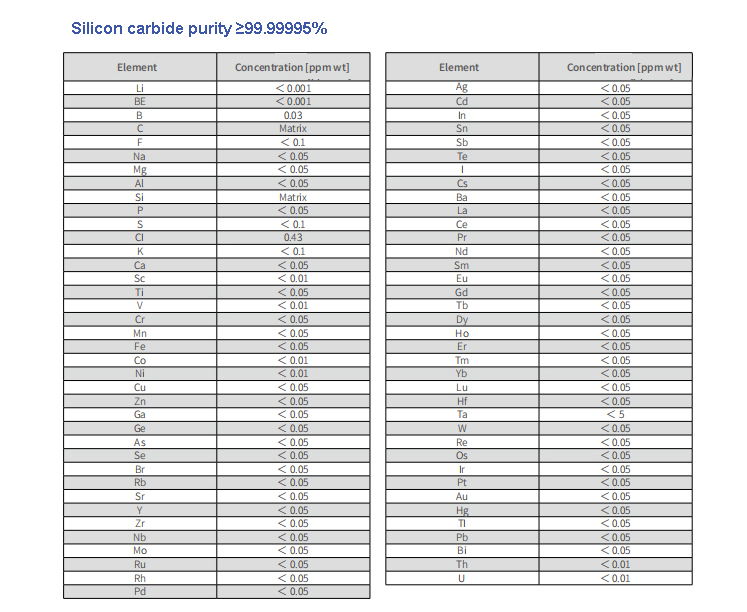

Mu ndondomeko ya semiconductor, ndondomeko yowonjezera makutidwe ndi okosijeni imafuna kuyeretsedwa kwakukulu kwa mankhwala, ndipo ku Semicera timapereka machitidwe ndi CVD zokutira ntchito zambiri za silicon carbide.

Chithunzi chotsatirachi chikuwonetsa silicon carbide slurry ya Semicea ndi silicon carbide ng'anjo yamoto yomwe imatsukidwa mu 100.0- mlingowopanda fumbichipinda. Ogwira ntchito athu akugwira ntchito asanayambe kupaka. Kuyera kwa silicon carbide yathu kumatha kufika 99.99%, ndipo chiyero cha zokutira sic ndichoposa 99.99995%.

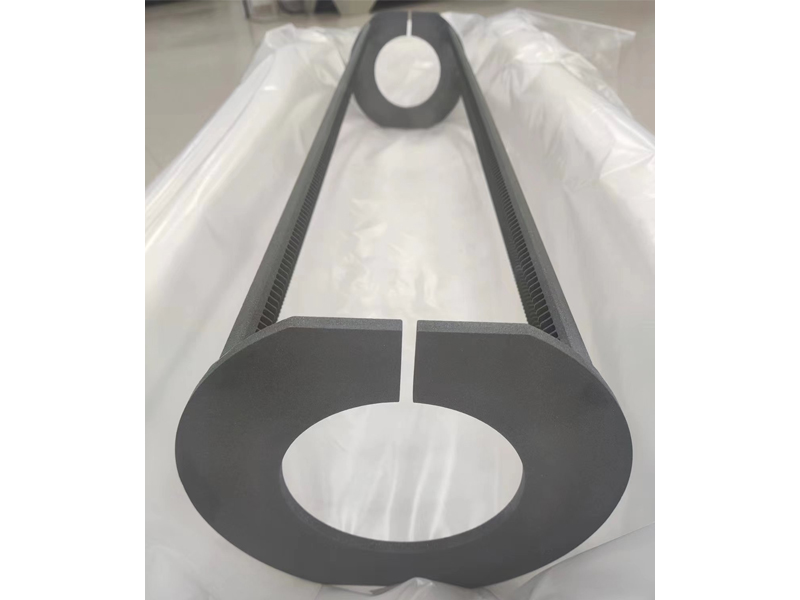

Yaiwisi Silicon Carbide Paddle ndi SiC Process Tube mu Cleaing

Silicon Carbide Wafer Boat CVD SiC Yokutidwa