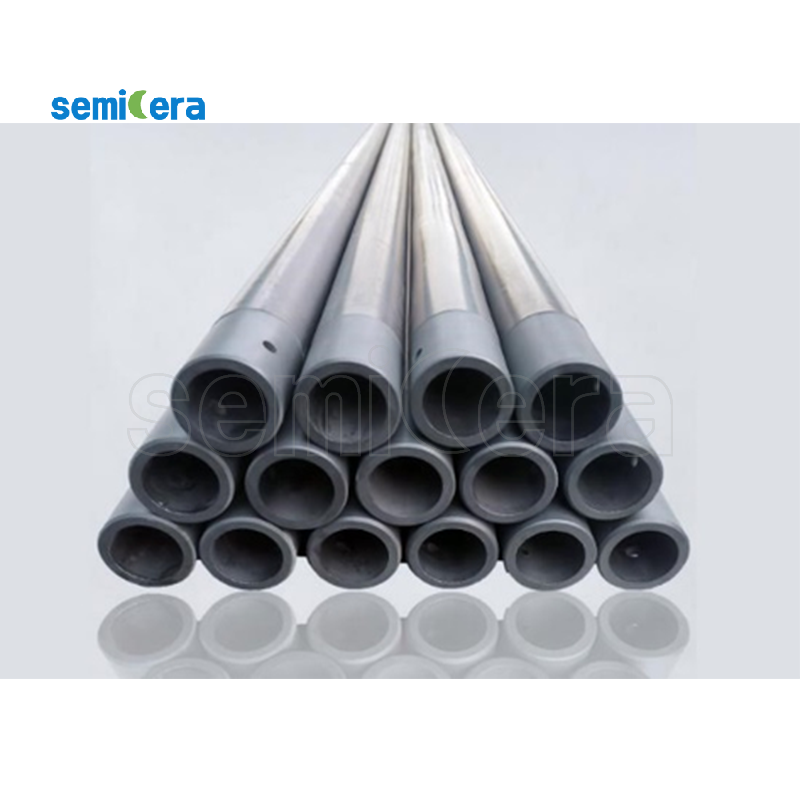

Silicon carbide ceramic mandrel ndi chinthu chooneka ngati ndodo chopangidwa ndi silicon carbide ceramic material. Silicon carbide ceramic mandrel ili ndi zinthu zabwino kwambiri zakuthupi komanso zamankhwala ndipo imagwiritsidwa ntchito kwambiri m'mafakitale potentha kwambiri, kupanikizika kwambiri komanso malo owononga.

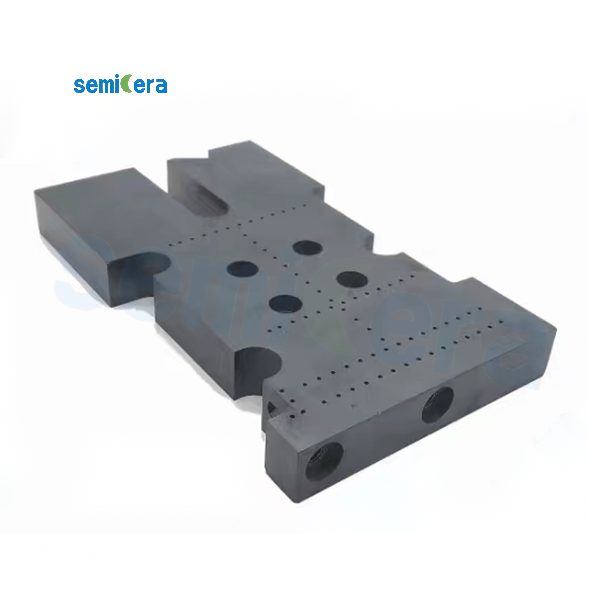

Silicon carbide ndi mtundu watsopano wama ceramic omwe ali ndi mtengo wokwera komanso zinthu zabwino kwambiri. Chifukwa cha mawonekedwe monga mphamvu yayikulu komanso kuuma, kukana kutentha kwambiri, kutenthetsa kwakukulu komanso kukana kwa dzimbiri, Silicon Carbide imatha kupirira pafupifupi mitundu yonse yamankhwala. Chifukwa chake, SiC imagwiritsidwa ntchito kwambiri mumigodi yamafuta, mankhwala, makina ndi airspace, ngakhale mphamvu zanyukiliya ndi asitikali ali ndi zofuna zawo zapadera pa SIC. Ntchito zina zomwe titha kupereka ndi mphete zosindikizira za mpope, valavu ndi zida zoteteza etc.

Maonekedwe ndi kukula akhoza makonda malinga ndi zofunika

Kuuma kwambiri (HV10): 22.2(Gpa)

Kachulukidwe kochepa kwambiri (3.10-3.20 g/cm³)

Pa kutentha mpaka 1400 ℃, SiC imatha kukhalabe ndi mphamvu

Chifukwa cha kukhazikika kwake kwamankhwala ndi thupi, SiC imakhala ndi kuuma kwakukulu komanso kukana dzimbiri.

Zofunikira zazikulu:

1. Kukhazikika kwa kutentha kwapamwamba: Silicon carbide ceramic mandrel ikhoza kukhalabe yokhazikika ya kapangidwe kake ndi ntchito mu malo otentha kwambiri. Ikhoza kupirira kutentha kwambiri ndipo imakhala ndi kutentha kwabwino kwambiri, komwe kuli koyenera kugwiritsidwa ntchito pazigawo zotentha kwambiri ndi zipangizo.

2. Kukana kwa dzimbiri: Silicon carbide ceramic mandrel imakhala ndi kukana kwa dzimbiri ndipo imatha kukana kukokoloka kwa zidulo, ma alkali, zosungunulira ndi zinthu zina zowononga. Sichidzagwira ntchito ndi mankhwala kapena kuwononga m'malo owononga, kusunga machitidwe ake oyambirira ndi kukhazikika.

3. Valani kukana: Silicon carbide ceramic mandrel imakhala ndi kuuma kwambiri komanso kukana kuvala, ndipo imatha kukhala yotsika kwambiri pothamanga kwambiri komanso mikangano yayikulu. Izi zimapangitsa kuti azikhala ndi moyo wautali komanso wodalirika m'malo ovuta kuvala.

4. Ntchito yabwino kwambiri yotchinjiriza: Silicon carbide ceramic mandrel imakhala ndi ntchito yabwino yotchinjiriza ndipo imatha kupereka chitetezo chodalirika chachitetezo pansi pa voteji yapamwamba komanso mikhalidwe yayikulu yamagetsi. Amagwiritsidwa ntchito kwambiri pazida zamphamvu kwambiri komanso zida zotchingira pamagetsi, zamagetsi ndi ma semiconductors.

5. Opepuka komanso amphamvu kwambiri: Silicon carbide ceramic mandrels ali ndi kachulukidwe kakang'ono komanso mphamvu yayikulu, ndipo amakhala ndi zida zabwino kwambiri zamakina. Amakhala ndi mphamvu yopindika kwambiri komanso yolimba ndipo amatha kupirira kuthamanga kwambiri komanso kupsinjika kwamakina.