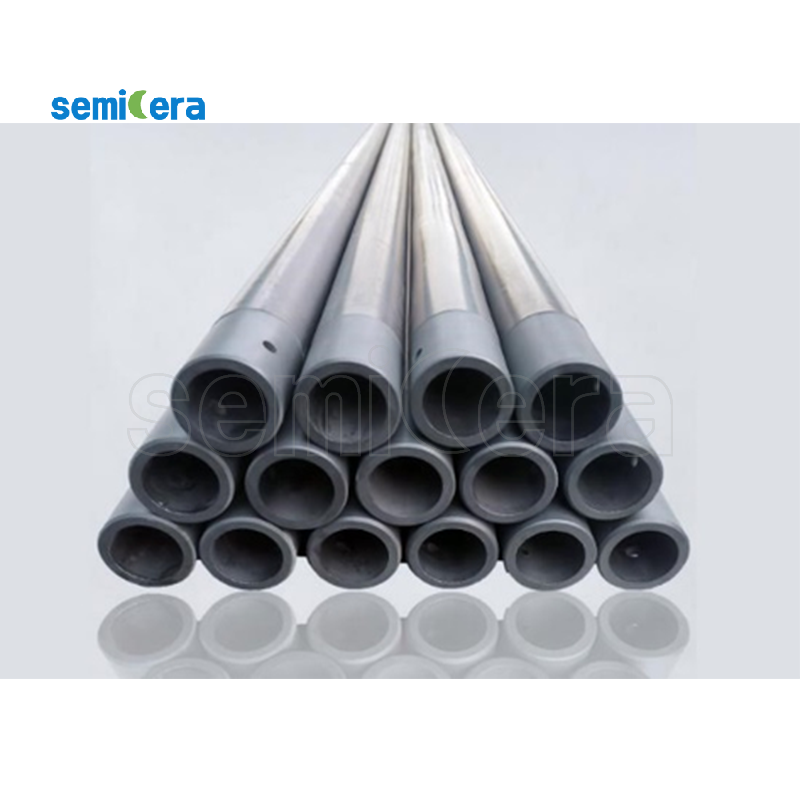

Ma roller a SiC ceramic ali ndi kukana kwabwino kwambiri ndipo amatha kupirira kuthamanga kwambiri komanso kukangana popanda kutaya mawonekedwe apamwamba. Kuuma kwake kuli pafupi ndi diamondi, zomwe zimathandiza kuti zichepetse bwino kukhudzana ndi zipangizo zachitsulo ndikuwonjezera moyo wautumiki wa wodzigudubuza. Kutsika kocheperako kwa SiC ceramic rollers kumachepetsanso kutayika kwa mphamvu komanso kutentha, ndikuwongolera kupanga bwino.

Kuphatikiza apo, ma roller a ceramic a SiC ali ndi kukana kwambiri kutentha kwambiri. Itha kugwira ntchito mokhazikika m'malo otentha kwambiri popanda kufewetsa kapena kupindika. Izi zimapangitsa ma SiC ceramic rollers kukhala oyenera kwambiri pakuwongolera kutentha kwambiri monga kugudubuza kwachitsulo ndi kuponyedwa kosalekeza, kuwonetsetsa kuti odzigudubuza amakhalabe ndi magwiridwe antchito abwino komanso osasunthika pakutentha kwambiri.

SiC ceramic rollers imakhalanso ndi kukana kwa dzimbiri. Ikhoza kukana kukokoloka kwa mankhwala monga ma asidi, alkalis, solvents ndi mpweya wowononga, kusunga mapeto a pamwamba ndi magwiridwe antchito a zodzigudubuza. Izi zimapangitsa ma SiC ceramic rollers kuti azigwira bwino ntchito monga kukonza mankhwala ndi electroplating, kukulitsa moyo wautumiki wa zida ndikuwongolera kupanga.

Makhalidwe opepuka a SiC ceramic rollers amawapatsa mawonekedwe abwino kwambiri osasunthika komanso kuthekera kochepetsera kugwedezeka, potero amachepetsa kugwedezeka ndi phokoso, kumapangitsa kuti zida zizikhazikika komanso kutonthozedwa. Miyeso yake yeniyeni ndi malo athyathyathya amatsimikizira kukhazikika kwa roller ndi kusalala, zomwe zimapereka zotsatira zabwino kwambiri zazitsulo ndi kusindikiza.

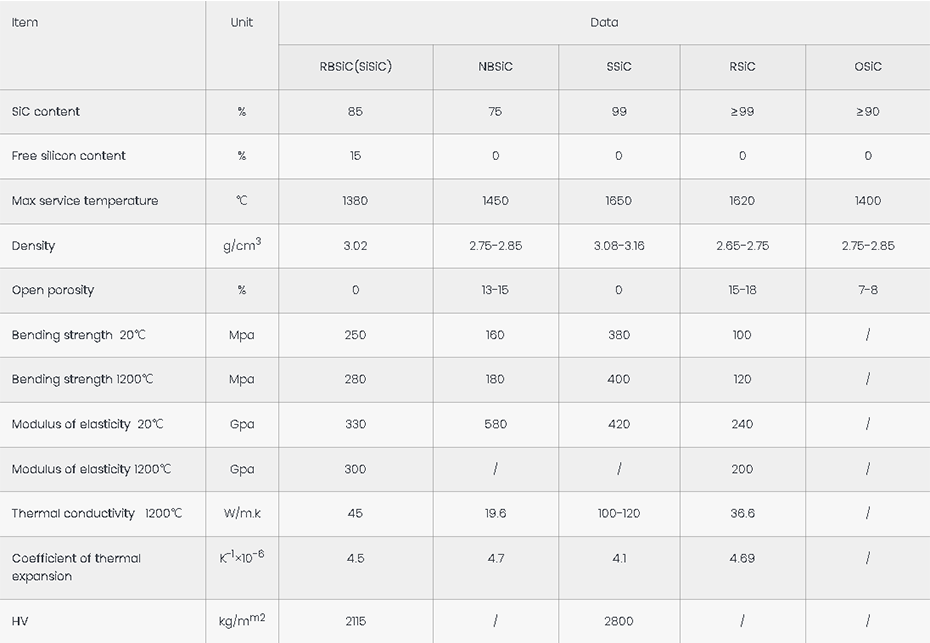

Non-pressure sintered silicon carbide wodzigudubuza, mumlengalenga kuthamanga sintered pakachitsulo carbide ceramic mankhwala, ntchito mkulu chiyero kopitilira muyeso silicon carbide ufa, sintered pa 2450 ℃ kutentha kwambiri, pakachitsulo carbide zili zoposa 99.1%, kachulukidwe mankhwala ≥3.10g/ cm3, palibe zonyansa zachitsulo monga silicon yachitsulo.

► Silicon carbide zili --≥99%;

► Kukana kutentha kwakukulu - kugwiritsa ntchito bwino pa 1800 ℃;

► High matenthedwe madutsidwe - poyerekeza ndi matenthedwe madutsidwe zipangizo graphite;

► Kuuma kwakukulu - kuuma kwachiwiri kwa diamondi, kiyubiki boron nitride;

► Kukana kwa dzimbiri - asidi amphamvu ndi alkali alibe dzimbiri, kukana kwa dzimbiri kuli bwino kuposa tungsten carbide ndi alumina;

► Kulemera kopepuka - kachulukidwe 3.10g/cm3, pafupi ndi aluminiyamu;

► Palibe kusinthika - kocheperako kakang'ono kwambiri pakukulitsa kutentha;

► Thermal shock resistance - zinthuzo zimatha kupirira kutentha kwachangu, kukana kutenthedwa kwa kutentha, kukana kuzizira ndi kutentha, kugwira ntchito mokhazikika.

Zofunikira zaukadaulo: