Silicon nitride (Si₃N₄) ceramics, monga zoumba zapamwamba kwambiri, zimakhala ndi zinthu zabwino kwambiri monga kukana kutentha kwambiri, mphamvu zambiri, kulimba kwambiri, kulimba kwambiri, kukana kugwa, kukana makutidwe ndi okosijeni, komanso kukana kuvala. Kuphatikiza apo, amapereka kukana kwamphamvu kwamafuta, ma dielectric, matenthedwe apamwamba kwambiri, komanso magwiridwe antchito apamwamba kwambiri amagetsi amagetsi. Zida zodziwika bwino izi zimawapangitsa kuti azigwiritsidwa ntchito kwambiri pazinthu zomangika, makamaka muzamlengalenga ndi magawo ena apamwamba kwambiri.

Komabe, Si₃N₄, pokhala gulu lomwe lili ndi zomangira zolimba, zimakhala ndi dongosolo lokhazikika lomwe limapangitsa kuti sintering to high density kukhala yovuta kupyolera mu kufalikira kwa boma lokha. Kulimbikitsa sintering, sintering aids, monga zitsulo oxides (MgO, CaO, Al₂O₃) ndi osowa nthaka oxides (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), amawonjezedwa kuti atsogolere kachulukidwe kudzera madzi-gawo sintering makina.

Pakadali pano, ukadaulo wapadziko lonse lapansi wa zida za semiconductor ukupita patsogolo kumagetsi okwera, mafunde akulu, komanso kuchulukira kwamagetsi. Kafukufuku wokhudza njira zopangira zoumba za Si₃N₄ ndizochuluka. Nkhaniyi ikuwonetsa njira zopangira sintering zomwe zimasinthitsa kachulukidwe komanso zida zonse zamakina a silicon nitride ceramics.

Njira Zodziwika Zophatikiza za Si₃N₄ Ceramics

Kuyerekeza kwa Magwiridwe a Si₃N₄ Ceramics Okonzedwa ndi Njira Zosiyanasiyana Zopangira Sintering

1. Reactive Sintering (RS):Reactive sintering inali njira yoyamba yomwe imagwiritsidwa ntchito pokonzekera mafakitale a Si₃N₄ ceramics. Ndizosavuta, zotsika mtengo, komanso zimatha kupanga mawonekedwe ovuta. Komabe, imakhala ndi nthawi yayitali yopanga zinthu, zomwe sizikugwirizana ndi kupanga mafakitale.

2. Pressureless Sintering (PLS):Izi ndi zofunika kwambiri ndi yosavuta sintering ndondomeko. Komabe, pamafunika zida zapamwamba za Si₃N₄ ndipo nthawi zambiri zimabweretsa zoumba zokhala ndi kachulukidwe kakang'ono, kuchepa kwakukulu, komanso chizolowezi chosweka kapena kupunduka.

3. Hot-Press Sintering (HP):Kugwiritsa ntchito uniaxial mechanical pressure kumawonjezera mphamvu yoyendetsa sintering, kulola kuti ziwiya zadothi zipangidwe pa kutentha kwa 100-200 ° C kutsika kusiyana ndi zomwe zimagwiritsidwa ntchito popukuta mopanda mphamvu. Njira imeneyi nthawi zambiri imagwiritsidwa ntchito popanga ziwiya zadothi zooneka ngati chipika koma zimakhala zovuta kukwaniritsa makulidwe ndi mawonekedwe a zinthu zapansi panthaka.

4. Spark Plasma Sintering (SPS):SPS imadziwika ndi sintering mwachangu, kukonza tirigu, komanso kuchepetsa kutentha kwa sintering. Komabe, SPS imafuna ndalama zambiri pazida, komanso kukonza zopangira matenthedwe apamwamba a Si₃N₄ ceramics kudzera pa SPS akadali pagawo loyesera ndipo sikunapangidwebe mafakitale.

5. Gas-Pressure Sintering (GPS):Pogwiritsa ntchito mphamvu ya gasi, njirayi imalepheretsa kuwonongeka kwa ceramic ndi kuwonda pa kutentha kwakukulu. Ndikosavuta kupanga zoumba zolimba kwambiri komanso kumathandizira kupanga batch. Komabe, njira imodzi yokha ya gasi-pressure sintering imavutika kuti ipange zigawo zamapangidwe okhala ndi mtundu umodzi wamkati ndi kunja ndi kapangidwe. Kugwiritsa ntchito masitepe awiri kapena angapo sintering kungathe kuchepetsa kwambiri mpweya wa intergranular, kupititsa patsogolo matenthedwe, ndikuwonjezera katundu.

Komabe, kutentha kwambiri kwa sintering ya magawo awiri a gasi-pressure sintering kwapangitsa kuti kafukufuku wam'mbuyomu ayang'ane kwambiri pokonzekera magawo a ceramic a Si₃N₄ okhala ndi matenthedwe apamwamba komanso mphamvu yopindika yachipinda. Kafukufuku pa zoumba za Si₃N₄ zokhala ndi makina amakina ambiri komanso makina otenthetsera kwambiri ndizochepa.

Gas-Pressure Two-Step Sintering Njira ya Si₃N₄

Yang Zhou ndi ogwira nawo ntchito ku Chongqing University of Technology adagwiritsa ntchito njira yothandizira sintering ya 5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ kukonzekera zitsulo za ceramic za Si₃N₄ pogwiritsa ntchito njira imodzi ndi ziwiri za gasi-pressure sintering pa 1800 ° C. Ma ceramics a Si₃N₄ opangidwa ndi njira yopangira masitepe awiri anali ndi kachulukidwe kakang'ono komanso makina omveka bwino. Zotsatirazi zikufotokozera mwachidule zotsatira za sitepe imodzi ndi njira ziwiri za gasi-pressure sintering pa microstructure ndi makina a Si₃N₄ ceramic components.

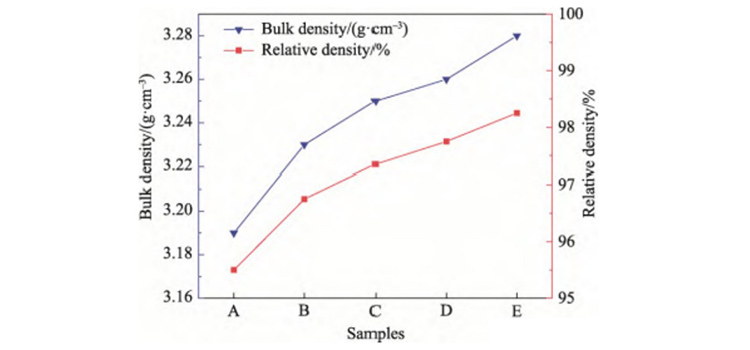

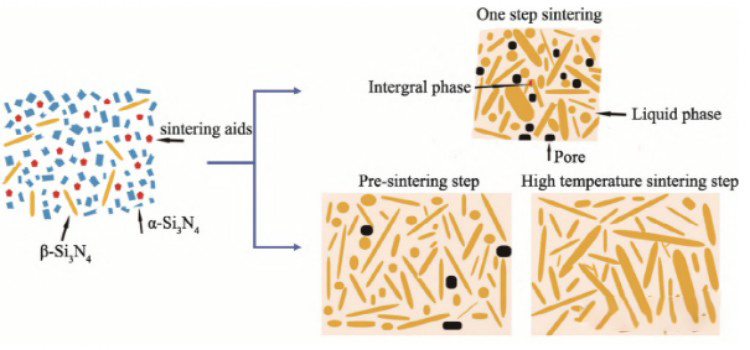

Kachulukidwe Kachulukidwe ka Si₃N₄ nthawi zambiri imakhala ndi magawo atatu, ndikulumikizana pakati pa magawowo. Gawo loyamba, kukonzanso tinthu tating'onoting'ono, ndipo gawo lachiwiri, kusungunuka - mpweya, ndi magawo ofunikira kwambiri pakukulitsa. Yokwanira anachita nthawi mu magawo amenewa kwambiri bwino chitsanzo kachulukidwe. Pamene kutentha kwa pre-sintering kwa ndondomeko ya sintering iwiri kumayikidwa ku 1600 ° C, mbewu za β-Si₃N₄ zimapanga chimango ndikupanga pores otsekedwa. Pambuyo pa sintering, kutentha kwina pansi pa kutentha kwakukulu ndi kuthamanga kwa nayitrogeni kumalimbikitsa kutuluka kwa madzi ndi kudzaza, zomwe zimathandiza kuthetsa ma pores otsekedwa, kupititsa patsogolo kachulukidwe kazitsulo za Si₃N₄. Choncho, zitsanzo opangidwa ndi masitepe awiri sintering ndondomeko amasonyeza apamwamba kachulukidwe ndi kachulukidwe wachibale kuposa opangidwa ndi sitepe sintering.

Gawo ndi Microstructure Pa sitepe sintering, nthawi yopezeka tinthu kukonzanso ndi njere malire mayamwidwe ndi yochepa. Mu njira ziwiri za sintering, sitepe yoyamba imachitika pa kutentha kochepa komanso kuthamanga kwa mpweya wochepa, komwe kumawonjezera nthawi yokonzanso tinthu ndipo kumabweretsa mbewu zazikulu. Kutentha kumawonjezeka kufika pamtunda wotentha kwambiri, kumene mbewu zimapitirizabe kukula kudzera mu njira yakucha ya Ostwald, kutulutsa zitsulo zolemera kwambiri za Si₃N₄.

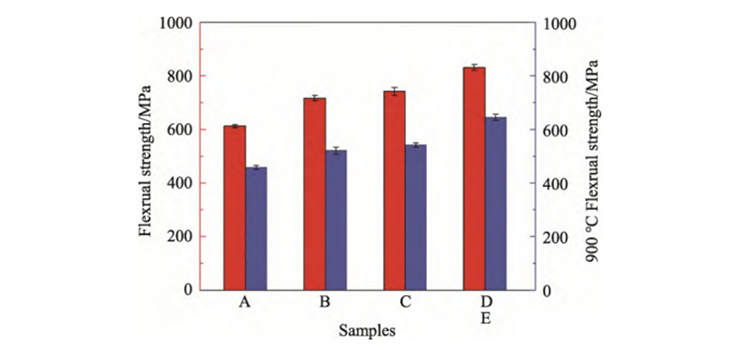

Zida Zamakina Kufewetsa kwa gawo la intergranular pa kutentha kwakukulu ndi chifukwa chachikulu cha kuchepa kwa mphamvu. Mu sintering imodzi, kukula kwambewu kosakhazikika kumapanga ma pores ang'onoang'ono pakati pa njere, zomwe zimalepheretsa kusintha kwakukulu pakutentha kwambiri. Komabe, munjira ziwiri za sintering, gawo lagalasi, lomwe limagawidwa mofanana mu malire a tirigu, ndipo mbewu zofananirako zimakulitsa mphamvu ya intergranular, zomwe zimapangitsa kuti pakhale mphamvu yopindika kwambiri.

Pomaliza, kugwira kwa nthawi yayitali pa sitepe imodzi sintering kungathandize kuchepetsa porosity mkati ndi kukwaniritsa mtundu wamkati wamkati ndi kapangidwe kake koma kungayambitse kukula kwambewu, komwe kumawononga zinthu zina zamakina. Pogwiritsa ntchito njira ziwiri zopangira sintering-kugwiritsa ntchito kutentha pang'ono kusanachitike kukulitsa nthawi yokonzanso tinthu komanso kutentha kwambiri kuti tilimbikitse kukula kwambewu zofanana-Si₃N₄ ceramic yokhala ndi kachulukidwe ka 98.25%, mawonekedwe ang'onoang'ono ofananirako, komanso makina abwino kwambiri amakina akhoza kukonzedwa bwino.

| Dzina | Gawo lapansi | Epitaxial wosanjikiza kapangidwe | Epitaxial ndondomeko | Epitaxial medium |

| Silicon homoepitaxial | Si | Si | Vapor Phase Epitaxy (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Sapphire kapena spinel | Si | Vapor Phase Epitaxy (VPE) | SiH₄+H₂ |

| GaAs homoepitaxial | Gas | Gas Gas | Vapor Phase Epitaxy (VPE) | AsCl₃+Ga+H₂ (Ar) |

| Gas | Gas Gas | Molecular Beam Epitaxy (MBE) | Ga+As | |

| GaAs heteroepitaxial | Gas Gas | GaAlAs/GaAs/GaAlAs | Liquid Phase Epitaxy (LPE) Gawo la Vapor (VPE) | Ga+Al+CaAs+ H2 Ga+AsH3+PH3+CHl+H2 |

| GaP homoepitaxial | GaP | GaP(GaP;N) | Liquid Phase Epitaxy (LPE) Liquid Phase Epitaxy (LPE) | Ga+GaP+H2+ (NH3) Ga+GaAs+GaP+NH3 |

| Superlattice | Gas | GaAlAs/GaAs (zungulira) | Molecular Beam Epitaxy (MBE) Mtengo wa MOCVD | Ca, As, Al GaR₃+AlR3+AsH3+H2 |

| InP homoepitaxial | InP | InP | Vapor Phase Epitaxy (VPE) Liquid Phase Epitaxy (LPE) | PCl3+Mu+H2 Mu+InAs+GaAs+InP+H₂ |

| Si/GaAs Epitaxy | Si | Gas | Molecular Beam Epitaxy (MBE) Mtengo wa MOGVD | Ga, monga GaR₃+AsH₃+H₂ |

Nthawi yotumiza: Dec-24-2024