Kodi Silicon Carbide SiC Coating ndi chiyani?

Kupaka kwa Silicon Carbide (SiC) ndiukadaulo wosinthika womwe umapereka chitetezo chapadera komanso magwiridwe antchito m'malo otentha kwambiri komanso okhathamira ndi mankhwala. Chophimba chapamwambachi chimagwiritsidwa ntchito pazinthu zosiyanasiyana, kuphatikizapo graphite, ceramics, ndi zitsulo, kuti ziwongolere katundu wawo, kupereka chitetezo chapamwamba ku dzimbiri, oxidation, ndi kuvala. Makhalidwe apadera a zokutira za SiC, kuphatikizapo kuyera kwawo kwakukulu, kutentha kwabwino kwambiri, ndi kukhulupirika kwapangidwe, zimawapangitsa kukhala abwino kugwiritsidwa ntchito m'mafakitale monga kupanga semiconductor, mlengalenga, ndi matekinoloje otenthetsera kwambiri.

Ubwino wa zokutira za silicon carbide

Kupaka kwa SiC kumapereka maubwino angapo omwe amawasiyanitsa ndi zokutira zoteteza zachikhalidwe:

- -Kutalikirana Kwambiri & Kukaniza Kuwonongeka

- Kapangidwe ka cubic SiC imatsimikizira zokutira kolimba kwambiri, kumathandizira kwambiri kukana dzimbiri ndikukulitsa moyo wa gawolo.

- -Kuwonekera Kwapadera Kwa Mawonekedwe Ovuta

- Kupaka kwa SiC kumadziwika chifukwa cha kuphimba kwake bwino, ngakhale m'mabowo ang'onoang'ono akhungu okhala ndi kuya mpaka 5 mm, opereka makulidwe a yunifolomu mpaka 30% pozama kwambiri.

- -Makonda Pamwamba Mwakali

- Njira yokutira imatha kusinthika, zomwe zimapangitsa kuti pakhale kuuma kosiyanasiyana kuti zigwirizane ndi zomwe mukufuna.

- -Kupaka Purity High

- Kutheka pogwiritsa ntchito mpweya woyeretsedwa kwambiri, zokutira za SiC zimakhalabe zoyera, zokhala ndi zonyansa zomwe zimakhala pansi pa 5 ppm. Kuyera kumeneku ndi kofunikira kwa mafakitale apamwamba omwe amafunikira kulondola komanso kuipitsidwa kochepa.

- -Kukhazikika kwamafuta

- Chophimba cha silicon carbide ceramic chimatha kupirira kutentha kwambiri, ndi kutentha kwapamwamba kwambiri mpaka 1600 ° C, kuonetsetsa kudalirika m'malo otentha kwambiri.

Kugwiritsa ntchito SiC Coating

Zovala za SiC zimagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana chifukwa chakuchita kwawo kosayerekezeka m'malo ovuta. Ntchito zazikuluzikulu zikuphatikiza:

- -LED & Solar Industry

- Chophimbacho chimagwiritsidwanso ntchito pazinthu zopangira ma LED ndi ma cell a solar, komwe kuyera kwambiri komanso kukana kutentha ndikofunikira.

- -Matekinoloje Otentha Otentha Kwambiri

- SiC yokutidwa ndi graphite ndi zida zina zimagwiritsidwa ntchito potenthetsa ng'anjo ndi ma reactor omwe amagwiritsidwa ntchito m'njira zosiyanasiyana zamafakitale.

- -Kukula kwa Crystal Semiconductor

- Mu kukula kwa kristalo wa semiconductor, zokutira za SiC zimagwiritsidwa ntchito kuteteza zigawo zomwe zimakhudzidwa ndi kukula kwa silicon ndi makristasi ena a semiconductor, omwe amapereka kukana kwa dzimbiri komanso kukhazikika kwamafuta.

- -Silicon ndi SiC Epitaxy

- Zovala za SiC zimagwiritsidwa ntchito pazigawo za epitaxial kukula kwa silicon ndi silicon carbide (SiC). Zopaka izi zimalepheretsa makutidwe ndi okosijeni, kuipitsidwa, ndikuwonetsetsa kuti zigawo za epitaxial ndizofunika kwambiri popanga zida zapamwamba za semiconductor.

- - Njira za Oxidation ndi Diffusion

- Zigawo zopangidwa ndi SiC zimagwiritsidwa ntchito popanga okosijeni ndi kufalikira, komwe zimapereka chotchinga chogwira ntchito motsutsana ndi zonyansa zosafunikira ndikuwonjezera kukhulupirika kwa chinthu chomaliza. Zopakazo zimakulitsa moyo wautali komanso kudalirika kwa zigawo zomwe zimakhudzidwa ndi kutentha kwambiri kwa okosijeni kapena masitepe ofalikira.

Zofunika Kwambiri za SiC Coating

Zovala za SiC zimapereka zinthu zingapo zomwe zimakulitsa magwiridwe antchito komanso kulimba kwa zida zomatira sic:

- -Mapangidwe a Crystal

- Chophimbacho chimapangidwa ndi aβ 3C (kiyubiki) galasikapangidwe, komwe ndi isotropic ndipo imapereka chitetezo chokwanira cha dzimbiri.

- -Kuchulukana ndi Porosity

- Zovala za SiC zimakhala ndi kachulukidwe wa3200kg/m³ndi chiwonetsero0% porosity, kuwonetsetsa kuti helium ikugwira bwino ntchito komanso kukana dzimbiri.

- -Zotentha ndi Zamagetsi

- Kupaka kwa SiC kumakhala ndi matenthedwe apamwamba kwambiri(200 W/m·K)ndi resistivity kwambiri magetsi(1MΩ·m), kuzipangitsa kukhala zabwino kwa mapulogalamu omwe amafunikira kasamalidwe ka kutentha ndi kusungunula magetsi.

- -Kulimba Kwamakina

- Ndi zotanuka modulus wa450 GPA, zokutira za SiC zimapereka mphamvu zamakina apamwamba, kupititsa patsogolo kukhulupirika kwa zigawo.

SiC silicon carbide zokutira Njira

Kupaka kwa SiC kumayikidwa kudzera mu Chemical Vapor Deposition (CVD), njira yomwe imaphatikizapo kuwola kwa mpweya kuti muyike zigawo zoonda za SiC pagawo lapansi. Njira yoyikayi imalola kukula kwakukulu komanso kuwongolera molondola pa makulidwe osanjikiza, omwe amatha kuyambira10 μm mpaka 500 µm, malinga ndi ntchito. Njira yokutira imatsimikiziranso kuphimba kofanana, ngakhale muzojambula zovuta monga mabowo ang'onoang'ono kapena akuya, omwe nthawi zambiri amakhala ovuta panjira zachikhalidwe.

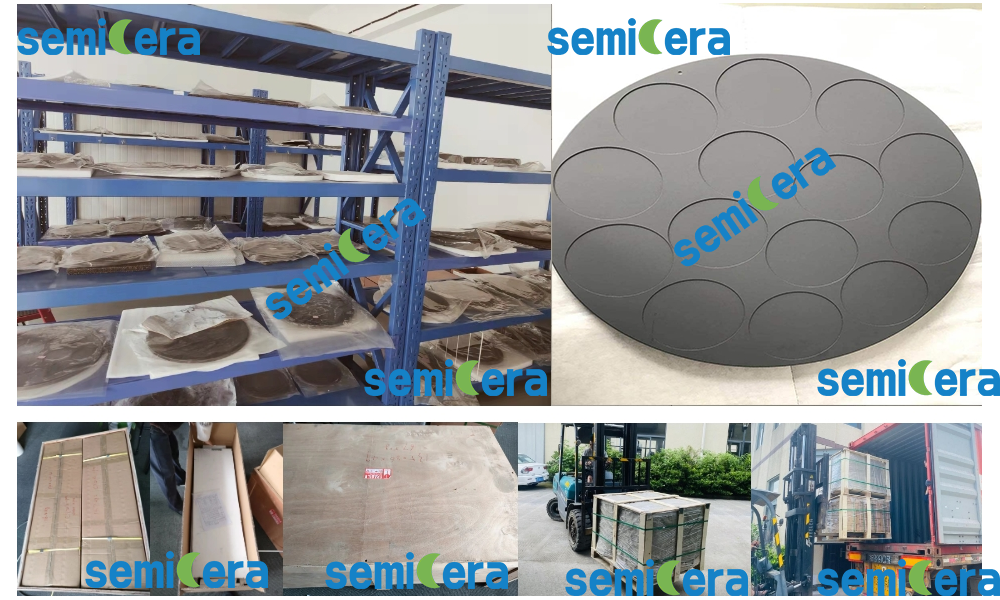

Zida Zoyenera Kupaka SiC

Zovala za SiC zitha kugwiritsidwa ntchito pazinthu zosiyanasiyana, kuphatikiza:

- - Ma graphite ndi Carbon Composites

- Graphite ndi gawo lapansi lodziwika bwino la zokutira za SiC chifukwa chamafuta ake abwino komanso magetsi. Kupaka kwa SiC kumalowa m'mitsempha ya graphite, kupanga mgwirizano wowonjezereka ndikupereka chitetezo chapamwamba.

- - Zojambula za ceramic

- Makatani opangidwa ndi silicon monga SiC, SiSiC, ndi RSiC amapindula ndi zokutira za SiC, zomwe zimapangitsa kuti zisawonongeke komanso kupewa kufalikira kwa zonyansa.

Chifukwa Chiyani Sankhani SiC Coating?

Zovala zapamtunda zimapereka njira yosunthika komanso yotsika mtengo kwa mafakitale omwe amafuna kuyera kwambiri, kukana dzimbiri, komanso kukhazikika kwamafuta. Kaya mukugwira ntchito mu semiconductor, zakuthambo, kapena zotenthetsera zogwira ntchito kwambiri, zokutira za SiC zimapereka chitetezo ndi magwiridwe antchito omwe mukufunikira kuti mupitirize kugwira ntchito bwino. Kuphatikizika kwa kachulukidwe kachubuki kakang'ono, mawonekedwe osinthika, komanso kuthekera kovala ma geometri ovuta kumatsimikizira kuti zinthu zokhala ndi sic zimatha kupirira ngakhale malo ovuta kwambiri.

Kuti mumve zambiri kapena kukambirana momwe zokutira za silicon carbide ceramic zingapindulire ndikugwiritsa ntchito kwanu, chondeLumikizanani nafe.

Nthawi yotumiza: Aug-12-2024