Mwa njira zonse zomwe zimakhudzidwa popanga chip, tsogolo lomaliza lamtandaAyenera kudulidwa m'madiresi a munthu aliyense ndi kuikidwa m'mabokosi ang'onoang'ono, otsekedwa ndi mapini ochepa okha owonekera. Chipcho chidzawunikidwa potengera momwe akulipirira, kukana, mayendedwe apano, ndi magetsi, koma palibe amene angaganizire mawonekedwe ake. Panthawi yopangira, timapukuta mobwerezabwereza kuti tikwaniritse planarization yofunikira, makamaka pa sitepe iliyonse ya photolithography. ThemtandaPamwamba payenera kukhala lathyathyathya kwambiri chifukwa, pamene njira yopangira tchipisi ikucheperachepera, disolo la makina a photolithography lifunika kukwanilitsa kusamvana kwa nanometer powonjezera kabowo ka manambala (NA) ka mandala. Komabe, izi nthawi imodzi zimachepetsa kuya kwa kuganizira (DoF). Kuzama kwa kuyang'ana kumatanthawuza kuya komwe makina owoneka bwino amatha kuyang'anitsitsa. Kuonetsetsa kuti chithunzi cha photolithography chikhale chomveka bwino komanso chokhazikika, kusiyana kwa pamwamba pamtandaziyenera kugwera mkati mwa kuya kwa kuyang'ana.

M'mawu osavuta, makina a photolithography amadzipereka kuwongolera luso lojambula bwino. Mwachitsanzo, makina a EUV photolithography a m'badwo watsopano ali ndi malo obowola manambala a 0.55, koma kuya kwake koyang'ana ndi ma nanometer 45 okha, okhala ndi mawonekedwe ang'onoang'ono oyerekeza pazithunzithunzi. Ngati ndimtandasi lathyathyathya, ali makulidwe osagwirizana, kapena pamwamba undulations, izo zingayambitse nkhani photolithography pa okwera ndi otsika mfundo.

Photolithography si njira yokhayo yomwe imafuna kuti ikhale yosalalamtandapamwamba. Njira zina zambiri zopangira tchipisi zimafunikanso kupukuta. Mwachitsanzo, pambuyo pa kunyowa, kupukuta kumafunika kusalaza pamwamba pake kuti kupaka ndi kuyika. Pambuyo pakudzipatula kwakuya (STI), kupukuta kumafunika kusalaza silicon dioxide yochulukirapo ndikumaliza kudzaza ngalandeyo. Pambuyo poyika zitsulo, kupukuta kumafunika kuti muchotse zigawo zazitsulo zochulukirapo ndikupewa mabwalo amfupi a chipangizo.

Choncho, kubadwa kwa chip kumaphatikizapo njira zambiri zopukutira kuti muchepetse kukhwinyata ndi kusiyanasiyana kwa pamwamba ndi kuchotsa zinthu zochulukirapo pamwamba. Kuphatikiza apo, zolakwika zapamtunda zomwe zimayambitsidwa ndi zovuta zosiyanasiyana pazakudya zowotcha nthawi zambiri zimangowonekera pambuyo popukuta. Chifukwa chake, mainjiniya omwe ali ndi udindo wopukuta amakhala ndi udindo waukulu. Ndiwo omwe ali pakati pakupanga chip ndipo nthawi zambiri amakhala ndi mlandu pamisonkhano yopanga. Ayenera kukhala odziwa bwino kunyowa komanso kutulutsa thupi, monga njira zazikulu zopukutira pakupanga chip.

Kodi njira zopukutira zoonda ndi ziti?

Njira zopukutira zitha kugawidwa m'magulu atatu akuluakulu kutengera mfundo zolumikizirana pakati pamadzi opukutira ndi pamwamba pa silicon wafer:

1. Njira Yoyezera Mwamakina:

Kupukuta kwamakina kumachotsa zotulukapo zopukutidwa podula ndi kupunduka kwa pulasitiki kuti pakhale malo osalala. Zida zodziwika bwino zimaphatikizapo miyala yamafuta, mawilo a ubweya, ndi sandpaper, zomwe zimagwiritsidwa ntchito ndi manja. Magawo apadera, monga mawonekedwe a matupi ozungulira, amatha kugwiritsa ntchito ma turntable ndi zida zina zothandizira. Pamalo okhala ndi zofunikira zapamwamba, njira zopukutira bwino kwambiri zitha kugwiritsidwa ntchito. Kupukuta kwabwino kwambiri kumagwiritsa ntchito zida zopangidwa mwapadera, zomwe, mumadzi opukutira okhala ndi abrasive, amakanikizidwa mwamphamvu pamwamba pa chogwirira ntchito ndikuzungulira mwachangu. Njirayi imatha kukhala ndi roughness pamwamba pa Ra0.008μm, yapamwamba kwambiri mwa njira zonse zopukutira. Njirayi imagwiritsidwa ntchito kwambiri popanga ma lens opangira ma lens.

2. Njira Yoyezera Ma Chemical:

Mankhwala kupukuta kumafuna kuvunda mwamakonda wa yaying'ono-protrusions pa zinthu padziko mu sing'anga mankhwala, chifukwa mu yosalala pamwamba. Ubwino waukulu wa njirayi ndi kusowa kwa zida zovuta, kutha kupukuta zida zooneka ngati zovuta, komanso kutha kupukuta zida zambiri panthawi imodzi ndikuchita bwino kwambiri. Nkhani yaikulu ya mankhwala kupukuta ndi mapangidwe amadzimadzi opukuta. Kuuma kwapamwamba komwe kumatheka chifukwa cha kupukuta kwamankhwala kumakhala ma micrometer angapo.

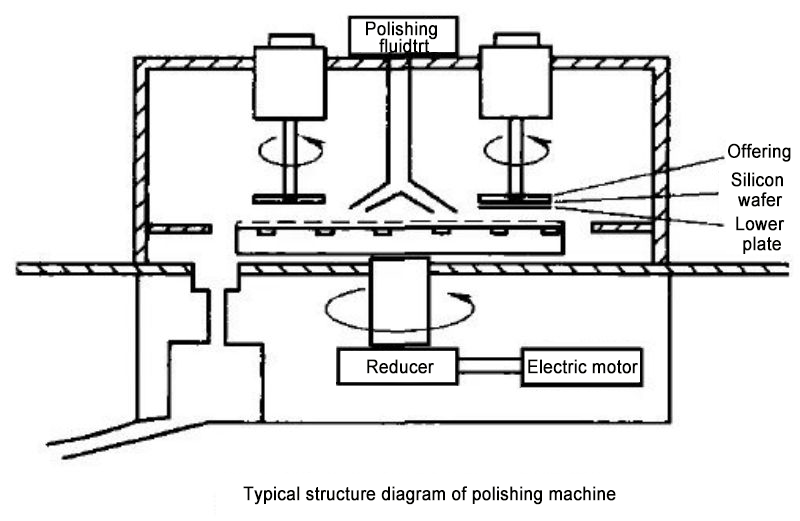

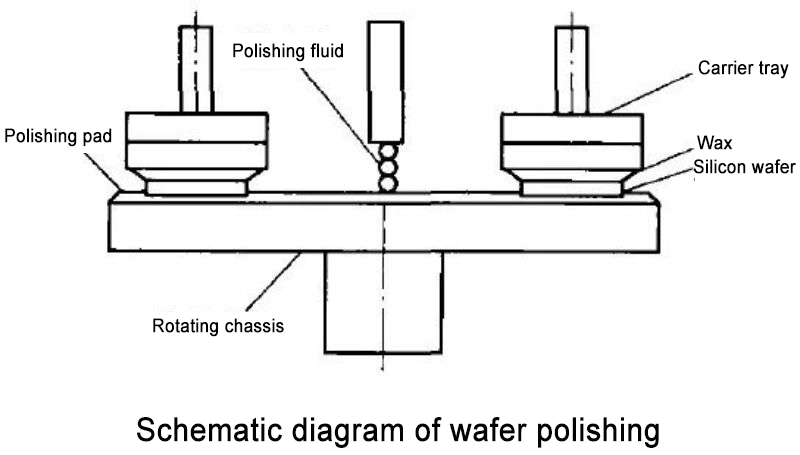

3. Chemical Mechanical polishing (CMP) Njira:

Njira ziwiri zoyambirira zopukutira zili ndi ubwino wake wapadera. Kuphatikizira njira ziwirizi kungathe kukwaniritsa zotsatira zowonjezera panthawiyi. Chemical makina kupukuta amaphatikiza mikangano yamakina ndi njira zowononga mankhwala. Panthawi ya CMP, ma reagents amankhwala mumadzi opukutira amatsitsimutsa gawo lapansi lopukutidwa, ndikupanga wosanjikiza wofewa wa okusayidi. Osayidi wosanjikiza uwu amachotsedwa kudzera mu kukangana kwamakina. Kubwereza makutidwe ndi okosijeni ndi makina kuchotsa ndondomeko amakwaniritsa bwino kupukuta.

Zovuta Zomwe Zilipo Panopa mu Chemical Mechanical polishing (CMP):

CMP ikukumana ndi zovuta ndi zovuta zingapo pazaukadaulo, zachuma, ndi kukhazikika kwa chilengedwe:

1) Kusasinthika kwadongosolo: Kukwaniritsa kusasinthika kwakukulu munjira ya CMP kumakhalabe kovuta. Ngakhale mkati mwa mzere womwewo wopangira, kusinthasintha kwakung'ono kwa magawo azinthu pakati pa magulu osiyanasiyana kapena zida zitha kukhudza kusasinthika kwa chinthu chomaliza.

2) Kusintha kwa Zida Zatsopano: Pamene zipangizo zatsopano zikupitiriza kuonekera, teknoloji ya CMP iyenera kusinthana ndi makhalidwe awo. Zida zina zapamwamba sizingagwirizane ndi njira zachikhalidwe za CMP, zomwe zimafuna kupangidwa kwa zakumwa zopukutira zosinthika komanso zomatira.

3) Kukula kwa Kukula: Pamene miyeso ya zida za semiconductor ikupitilira kuchepa, zovuta zomwe zimachitika chifukwa cha kukula zimakhala zofunikira kwambiri. Zing'onozing'ono zimafuna kutsetsereka kwapamwamba, zomwe zimafunikira njira zolondola za CMP.

4) Kuwongolera kwa Mtengo Wochotsa Zinthu: Muzogwiritsa ntchito zina, kuwongolera molondola kuchuluka kwa zinthu zochotsera zinthu zosiyanasiyana ndikofunikira. Kuwonetsetsa kuti ziwopsezo zochotsa mosasinthasintha m'magawo osiyanasiyana panthawi ya CMP ndikofunikira pakupanga zida zogwira ntchito kwambiri.

5) Ubwenzi Wachilengedwe: Zakumwa zopukutira ndi ma abrasives omwe amagwiritsidwa ntchito mu CMP amatha kukhala ndi zinthu zowononga chilengedwe. Kafukufuku ndi chitukuko cha njira zowongoka komanso zokhazikika za CMP ndizovuta zofunika.

6) Luntha ndi Zochita Zodzichitira: Ngakhale kuti nzeru ndi makina opangira makina a CMP akupita patsogolo pang'onopang'ono, amayenera kulimbana ndi zovuta komanso zosiyana siyana. Kukwaniritsa magawo apamwamba a makina opangira okha komanso kuyang'anira mwanzeru kuti muwongolere magwiridwe antchito ndizovuta zomwe ziyenera kuthetsedwa.

7) Kuwongolera Mtengo: CMP imaphatikizapo zida zapamwamba komanso ndalama zakuthupi. Opanga akuyenera kuwongolera magwiridwe antchito pomwe akuyesetsa kuchepetsa ndalama zopangira kuti apitilize kupikisana pamsika.

Nthawi yotumiza: Jun-05-2024