Ma Wafers ndiye zida zazikulu zopangira mabwalo ophatikizika, zida za discrete semiconductor ndi zida zamagetsi. Kupitilira 90% ya mabwalo ophatikizika amapangidwa pamiyala yoyera kwambiri, yapamwamba kwambiri.

Chida chokonzekera chophatikizika chimatanthawuza njira yopangira zida zopangira silicon imodzi kukhala silicon imodzi ya ndodo yamtundu wina ndi kutalika kwake, kenako ndikuyika zida zachitsulo za silicon imodzi pamakina opanga makina, chithandizo chamankhwala ndi njira zina.

Zipangizo zomwe zimapanga zowotcha za silicon kapena zowotcha za epitaxial silicon zomwe zimakwaniritsa kulondola kwa geometric ndi zofunikira zapamtunda ndipo zimapereka gawo lapansi lofunikira la silicon popanga chip.

Njira yoyendetsera yokonzekera zophika za silicon zokhala ndi mainchesi osakwana 200 mm ndi:

Kukula kwa krustalo limodzi → kudulidwa → kugudubuzika m'mimba mwake → kudula → kuseketsa → kugaya → etching → kupeza → kupukuta → kuyeretsa → epitaxy → kuyika, ndi zina zotero.

Njira yayikulu yoyendetsera kukonzekera zowotcha za silicon zokhala ndi mainchesi 300 mm ndi motere:

Kukula kwa krustalo limodzi → kupukuta → kugudubuza m'mimba mwake → kudula → kuseketsa → kupukuta pamwamba → kupukuta → kupukuta m'mphepete → kupukuta mbali ziwiri → kupukuta mbali imodzi → kuyeretsa komaliza → epitaxy/annealing → kulongedza, ndi zina zotero.

1.Silicon zinthu

Silicon ndi semiconductor material chifukwa ali 4 valence electron ndipo ali mu gulu IVA la periodic tebulo pamodzi ndi zinthu zina.

Chiwerengero cha ma elekitironi a valence mu silikoni amachiyika pakati pa kondakitala wabwino (1 valence electron) ndi insulator (8 valence electrons).

Silicon yoyera sapezeka m'chilengedwe ndipo iyenera kuchotsedwa ndikuyeretsedwa kuti ikhale yokwanira kupanga. Nthawi zambiri amapezeka mu silika (silicon oxide kapena SiO2) ndi ma silicates ena.

Mitundu ina ya SiO2 imaphatikizapo galasi, kristalo wopanda mtundu, quartz, agate ndi diso la mphaka.

Chinthu choyamba chomwe chinagwiritsidwa ntchito ngati semiconductor chinali germanium m'ma 1940 ndi kumayambiriro kwa zaka za m'ma 1950, koma mwamsanga chinasinthidwa ndi silicon.

Silicon idasankhidwa kukhala chinthu chachikulu cha semiconductor pazifukwa zinayi:

Kuchuluka kwa Zida za Silicon: Silicon ndi chinthu chachiwiri chochuluka kwambiri padziko lapansi, chomwe chimapanga 25% ya kutumphuka kwa dziko lapansi.

Malo osungunuka kwambiri a zinthu za silicon amalola kulolerana kwakukulu: malo osungunuka a silicon pa 1412 ° C ndi apamwamba kwambiri kuposa malo osungunuka a germanium pa 937 ° C. Malo osungunuka kwambiri amalola silicon kupirira njira zotentha kwambiri.

Zida za silicon zimakhala ndi kutentha kwakukulu kogwira ntchito;

Kukula kwachilengedwe kwa silicon oxide (SiO2): SiO2 ndi yamtengo wapatali, yokhazikika yotchinga magetsi ndipo imakhala ngati chotchinga chabwino kwambiri chamankhwala kuteteza silicon ku kuipitsidwa kwakunja. Kukhazikika kwamagetsi ndikofunikira kuti tipewe kutayikira pakati pa ma conductor oyandikana nawo mabwalo ophatikizika. Kutha kukulitsa zigawo zoonda zokhazikika za zinthu za SiO2 ndizofunikira kwambiri popanga zida zapamwamba kwambiri za metal-oxide semiconductor (MOS-FET). SiO2 ili ndi zida zamakina zofanana ndi silicon, zomwe zimalola kukonza kutentha kwambiri popanda kuwotcha kwambiri kwa silicon.

2.Wafer kukonzekera

Zophika za semiconductor zimadulidwa kuchokera kuzinthu zambiri za semiconductor. Zinthu za semiconductor izi zimatchedwa crystal rod, yomwe imakula kuchokera ku chipika chachikulu cha polycrystalline ndi zinthu zosasinthika zamkati.

Kusandutsa chipika cha polycrystalline kukhala kristalo imodzi yayikulu ndikuipatsa mawonekedwe olondola a kristalo ndi kuchuluka koyenera kwa mtundu wa N kapena mtundu wa P-doping kumatchedwa kukula kwa kristalo.

Ukadaulo wodziwika bwino wopangira ma crystal silicon ingots pokonzekera silicon wafer ndi njira ya Czochralski ndi njira yosungunulira zone.

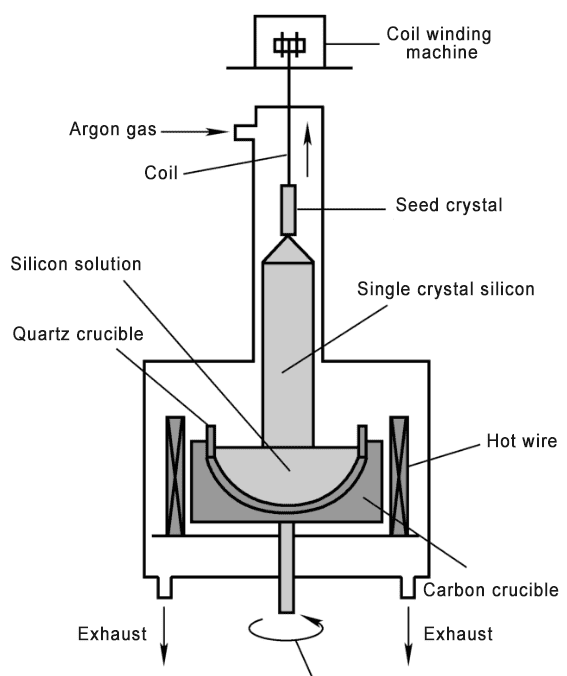

2.1 Czochralski njira ndi Czochralski single crystal ng'anjo

Njira ya Czochralski (CZ), yomwe imadziwikanso kuti njira ya Czochralski (CZ), imatanthawuza njira yosinthira madzi osungunuka a semiconductor-grade silicon kukhala ma ingots olimba a crystal silicon okhala ndi mawonekedwe olondola a kristalo ndikulowetsa mumtundu wa N kapena P- mtundu.

Pakalipano, oposa 85% a silicon imodzi ya crystal amakula pogwiritsa ntchito njira ya Czochralski.

Ng'anjo ya Czochralski single crystal ng'anjo imatanthawuza zida zopangira zomwe zimasungunula zinthu zoyera kwambiri za polysilicon kukhala zamadzimadzi powotcha pamalo otetezedwa otsekeka kwambiri kapena gasi (kapena gasi wa inert), kenako ndikuzikonzanso kuti zipange zida za silicon imodzi yokhala ndi zinthu zina zakunja. miyeso.

Mfundo yogwirira ntchito ya ng'anjo ya kristalo imodzi ndi njira yakuthupi ya polycrystalline silicon material recrystallizing mu single crystal silicon material in a liquid state.

CZ single crystal ng'anjo imatha kugawidwa m'magawo anayi: thupi la ng'anjo, makina otumizira makina, kutentha ndi kuwongolera kutentha, ndi njira yotumizira mpweya.

Thupi la ng'anjo limaphatikizapo ng'anjo ya ng'anjo, axis ya kristalo ya mbewu, crucible ya quartz, supuni ya doping, chivundikiro cha kristalo wa mbewu, ndi zenera lowonera.

Mng'anjo ya ng'anjo ndikuonetsetsa kuti kutentha kwa ng'anjo kumagawidwa mofanana ndipo kumatha kutulutsa kutentha bwino; chingwe cha kristalo cha mbewu chimagwiritsidwa ntchito poyendetsa kristalo wa mbewu kusuntha ndi kutsika ndikuzungulira; zonyansa zomwe zimayenera kutayidwa zimayikidwa mu supuni ya doping;

Chophimba cha kristalo wa mbewu ndikuteteza kristalo wa mbewu kuti zisaipitsidwe. Njira yotumizira makina imagwiritsidwa ntchito makamaka poyendetsa kayendedwe ka kristalo wa mbewu ndi crucible.

Pofuna kuonetsetsa kuti yankho la silicon silikhala oxidized, digiri ya vacuum mu ng'anjo imayenera kukhala yokwera kwambiri, nthawi zambiri pansi pa 5 Torr, ndipo chiyero cha mpweya wowonjezera wowonjezera uyenera kukhala pamwamba pa 99.9999%.

Chidutswa chimodzi cha crystal silicon chokhala ndi mawonekedwe a kristalo omwe amafunidwa chimagwiritsidwa ntchito ngati kristalo wa mbewu kukulitsa ingot ya silicon, ndipo silicon ingot yomwe yakula imakhala ngati chithunzi cha kristalo wa mbewu.

Mikhalidwe yomwe ili pakati pa silicon yosungunuka ndi kristalo imodzi ya crystal silicon iyenera kuyendetsedwa bwino. Izi zimatsimikizira kuti silicon yopyapyala imatha kubwereza molondola kapangidwe ka kristalo wa mbewu ndipo pamapeto pake imakula kukhala ingot yayikulu ya crystal silicon.

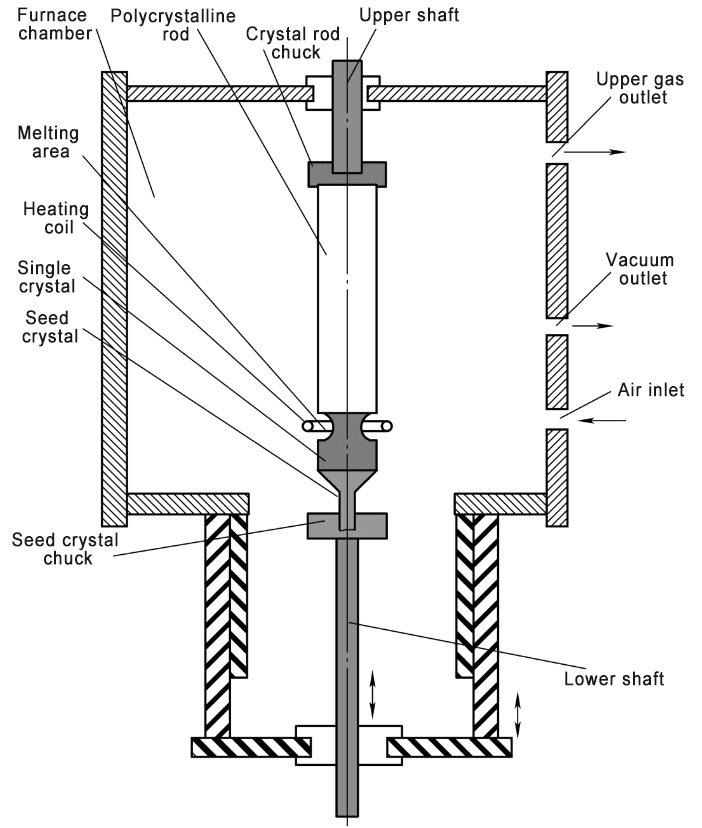

2.2 Njira Yosungunula Magawo ndi Ng'anjo ya Crystal Imodzi

Njira yoyandama (FZ) imapanga ma ingots a crystal a silicon omwe amakhala ndi okosijeni ochepa kwambiri. Njira yoyendetsera zone idapangidwa m'zaka za m'ma 1950 ndipo imatha kupanga silicon imodzi yoyera kwambiri mpaka pano.

Zone melting single crystal ng'anjo imatanthawuza ng'anjo yomwe imagwiritsa ntchito mfundo yosungunula madera kuti ipangitse malo ocheperako osungunuka mu ndodo ya polycrystalline kudzera pagawo lotentha kwambiri lotsekeka la ng'anjo ya polycrystalline ndodo muvuvu lalikulu kapena gasi wosowa wa quartz. chitetezo chilengedwe.

Chida chowongolera chomwe chimasuntha ndodo ya polycrystalline kapena chotenthetsera cha ng'anjo kusuntha malo osungunuka ndikuwunikira pang'onopang'ono kukhala ndodo imodzi ya kristalo.

Makhalidwe a kukonzekera ndodo imodzi ya kristalo ndi njira yosungunuka ya zone ndikuti chiyero cha ndodo za polycrystalline chikhoza kusinthidwa mu ndondomeko ya crystallization mu ndodo imodzi ya kristalo, ndipo kukula kwa doping kwa zipangizo za ndodo kumakhala kofanana.

Mitundu ya ng'anjo za kristalo zosungunula zone zitha kugawidwa m'mitundu iwiri: ng'anjo zoyandama zosungunula ng'anjo za kristalo zomwe zimadalira kugwedezeka kwapamtunda ndi ng'anjo yopingasa yosungunuka imodzi. Pakugwiritsa ntchito, ng'anjo zosungunula zamtundu umodzi nthawi zambiri zimagwiritsa ntchito kusungunula koyandama.

Zone yosungunula ng'anjo ya kristalo imodzi imatha kukonzekera silicon imodzi ya crystal yoyera kwambiri yopanda okosijeni popanda kufunikira kwa crucible. Amagwiritsidwa ntchito kwambiri pokonzekera kukana kwambiri (> 20kΩ·cm) crystal crystal silicon ndikuyeretsa silicon yosungunuka. Zogulitsazi zimagwiritsidwa ntchito kwambiri popanga zida zamagetsi zamagetsi.

Mng'anjo ya kristalo yomwe imasungunuka imakhala ndi chipinda choyatsira moto, shaft yakumtunda ndi shaft yotsika (gawo lotumizira makina), chuck crystal rod, chuck crystal chuck, chowotcha chotenthetsera (jenereta yapamwamba), madoko a gasi (doko la vacuum, polowera gasi, chotengera chapamwamba cha gasi), etc.

Mu chipinda cha chipinda cha ng'anjo, kuyendayenda kwa madzi ozizira kumakonzedwa. Mapeto apansi a shaft yapamwamba ya ng'anjo imodzi ya kristalo ndi chuck ya crystal rod chuck, yomwe imagwiritsidwa ntchito kukakamiza ndodo ya polycrystalline; Kumapeto kwa tsinde lakumunsi ndi kristalo wa mbewu, womwe umagwiritsidwa ntchito kukakamiza kristalo wa mbewu.

Mphamvu yamagetsi yothamanga kwambiri imaperekedwa kwa koyilo yotentha, ndipo malo ocheperako osungunuka amapangidwa mu ndodo ya polycrystalline kuyambira kumapeto kwenikweni. Panthawi imodzimodziyo, nkhwangwa zakumtunda ndi zapansi zimazungulira ndi kutsika, kotero kuti malo osungunuka amawonekera mu kristalo imodzi.

Ubwino wa zone kusungunuka ng'anjo imodzi ya kristalo ndikuti sikungowonjezera chiyero cha kristalo wokonzeka, komanso kupangitsa kukula kwa doping kukhala kofanana, ndipo ndodo imodzi ya kristalo imatha kuyeretsedwa kudzera munjira zingapo.

Kuipa kwa zone kusungunula ng'anjo imodzi ya kristalo ndi mtengo wokwera komanso wocheperako wa kristalo wokonzeka. Pakalipano, kutalika kwake kwa kristalo imodzi yomwe ingakonzekeredwe ndi 200mm.

Kutalika konse kwa ng'anjo ya ng'anjo ya kristalo imodzi ndikokwera kwambiri, ndipo kugunda kwa nkhwangwa zakumtunda ndi zam'munsi kumakhala kotalika, kotero kuti ndodo zazitali za kristalo zimatha kukula.

3. Wafer processing ndi zipangizo

Ndodo ya kristalo imayenera kudutsa njira zingapo kuti ipange gawo lapansi la silicon lomwe limakwaniritsa zofunikira pakupanga semiconductor, chomwe ndi chowotcha. The Basic process of processing ndi:

Kupunthwa, kudula, kudula, kuwotcha annealing, chamfering, kupera, kupukuta, kuyeretsa ndi kulongedza, etc.

3.1 Kuwongolera kwa Wafer

Popanga silicon ya polycrystalline ndi silicon ya Czochralski, silicon imodzi ya crystal imakhala ndi okosijeni. Pa kutentha kwina, mpweya mu crystal silicon imodzi udzapereka ma elekitironi, ndipo mpweya umasinthidwa kukhala opereka mpweya. Ma elekitironi awa adzaphatikizana ndi zonyansa mu kachitsulo kakang'ono ka silicon ndikukhudza kukhazikika kwa chopha cha silicon.

Ng'anjo yowonjezera: imatanthawuza ng'anjo yomwe imakweza kutentha kwa ng'anjo kufika 1000-1200 ° C mu hydrogen kapena argon chilengedwe. Mwa kusunga kutentha ndi kuziziritsa, mpweya womwe uli pafupi ndi pamwamba pa silicon wopukutidwa umatenthedwa ndikuchotsedwa pamwamba pake, zomwe zimapangitsa kuti mpweya ukhale wochuluka komanso wosanjikiza.

Zida zamakina zomwe zimasungunula zolakwika zazing'ono pamwamba pa zowotcha za silicon, zimachepetsa kuchuluka kwa zonyansa pafupi ndi pamwamba pa zowotcha za silicon, zimachepetsa zilema, ndikupanga malo oyera kwambiri pamwamba pa zowotcha za silicon.

Ng'anjo yamoto imatchedwanso ng'anjo yotentha kwambiri chifukwa cha kutentha kwake. Makampaniwa amatchanso njira yopangira silicon wafer annealing.

Silicon wafer annealing ng'anjo imagawidwa mu:

- Horizontal annealing ng'anjo;

-Oima annealing ng'anjo;

-Nng'anjo yowotchera mwachangu.

Kusiyana kwakukulu pakati pa ng'anjo yopingasa yopingasa ndi ng'anjo yowongoka ndikuyika momwe chipindacho chikuchitikira.

Chipinda chochitiramo ng'anjo yopingasa yopingasa ndi chopingasa, ndipo gulu la zowotcha za silicon zitha kukwezedwa muchipinda chochitiramo cha ng'anjo yowotcherayo kuti itenthedwe nthawi yomweyo. Nthawi yotsekera nthawi zambiri imakhala mphindi 20 mpaka 30, koma chipinda chochitirako chimafunika nthawi yayitali yotenthetsera kuti ifike kutentha komwe kumafunikira.

The ndondomeko ofukula annealing ng'anjo komanso utenga njira imodzi Kutsegula mtanda wa pakachitsulo zopyapyala mu anachita chipinda cha ng'anjo annealing kwa annealing mankhwala. Chipinda chochitiramo chimakhala ndi mawonekedwe oyima, omwe amalola kuti zowotcha za silicon ziyikidwe mu bwato la quartz mopingasa.

Panthawi imodzimodziyo, popeza bwato la quartz limatha kuzungulira lonse mu chipinda chochitira, kutentha kwa annealing kwa chipinda chochitiramo ndi yunifolomu, kugawa kwa kutentha kwa silicon wafer ndi yunifolomu, ndipo ili ndi makhalidwe abwino kwambiri ogwirizanitsa. Komabe, mtengo wa ng'anjo yowongoka ndi wokwera kuposa wa ng'anjo yopingasa.

Ng'anjo yowotcha mwachangu imagwiritsa ntchito nyali ya halogen tungsten kuti itenthetse mwachindunji chowotcha cha silicon, chomwe chimatha kutenthetsa mwachangu kapena kuzizirira mosiyanasiyana 1 mpaka 250 ° C/s. Kutentha kapena kuziziritsa kumathamanga kwambiri kuposa ng'anjo yachikhalidwe. Zimangotenga masekondi pang'ono kuti mutenthe kutentha kwa chipindacho kufika pamwamba pa 1100 ° C.

—————————————————————————————————————————————————— —-

Semicera ikhoza kuperekazigawo za graphite,zofewa/zokhazikika,zida za silicon carbide, Zigawo za CVD silicon carbide,ndiZigawo zokutira za SiC/TaCndi njira yonse ya semiconductor m'masiku 30.

Ngati mukufuna zinthu za semiconductor pamwambapa, chonde musazengereze kulumikizana nafe nthawi yoyamba.

Tel: +86-13373889683

Watsapp: +86-15957878134

Email: sales01@semi-cera.com

Nthawi yotumiza: Aug-26-2024