1. Mawu Oyamba

Njira yophatikizira zinthu (zopangira) pamwamba pa zinthu zapansi panthaka pogwiritsa ntchito njira zakuthupi kapena zamankhwala zimatchedwa kukula kwa filimu yopyapyala.

Malinga ndi mfundo zosiyanasiyana ntchito, Integrated dera woonda filimu mafunsidwe akhoza kugawidwa mu:

-Kuyika Nthunzi Pathupi (PVD);

-Chemical Vapor Deposition (CVD);

-Kuwonjezera.

2. Njira Yakukula Kwa Mafilimu Ochepa

2.1 Kuyika kwa nthunzi pathupi ndi kutulutsa mpweya

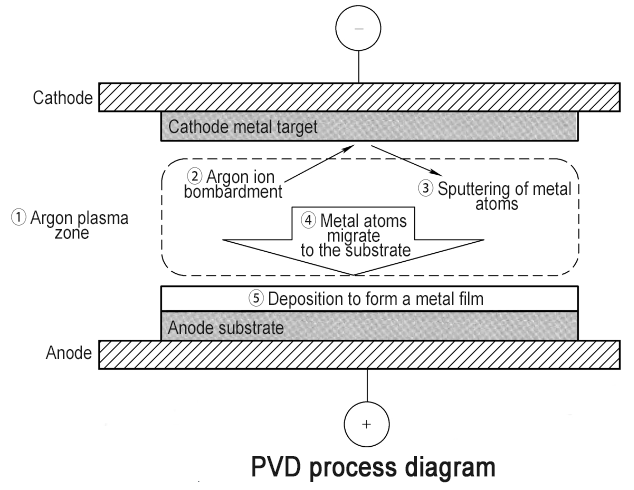

The physical vapor deposition (PVD) ndondomeko imatanthawuza kugwiritsa ntchito njira zakuthupi monga vacuum evaporation, sputtering, plasma coating ndi molecular beam epitaxy kuti apange filimu yopyapyala pamwamba pa nsalu yopyapyala.

M'makampani a VLSI, ukadaulo wa PVD womwe umagwiritsidwa ntchito kwambiri ndi sputtering, womwe umagwiritsidwa ntchito kwambiri popangira ma elekitirodi ndi ma interconnects achitsulo a mabwalo ophatikizika. Kupopera ndi njira yomwe mipweya yosowa [monga argon (Ar)] imalowetsedwa mu ayoni (monga Ar +) pansi pa mphamvu yamagetsi akunja pansi pazitali za vacuum, ndikuphulitsa gwero lazinthu zomwe zimayang'ana pansi pamagetsi apamwamba, kugogoda maatomu kapena mamolekyu a zinthu zomwe mukufuna, ndiyeno kufika pamwamba pa mtandawo kupanga filimu yopyapyala pambuyo pa kugunda kopanda kugunda. Ar ali ndi mankhwala okhazikika, ndipo ma ions ake sangagwirizane ndi mankhwala ndi zinthu zomwe mukufuna komanso filimuyo. Monga tchipisi tating'onoting'ono tomwe timalowa mu nthawi ya 0.13μm yamkuwa yolumikizirana, chotchinga chamkuwa chimagwiritsa ntchito filimu ya titanium nitride (TiN) kapena tantalum nitride (TaN). Kufunika kwaukadaulo wamafakitale kwalimbikitsa kafukufuku ndi chitukuko chaukadaulo wamankhwala osokoneza bongo, ndiye kuti, mchipinda chothirira, kuwonjezera pa Ar, palinso mpweya wa nayitrogeni (N2), kotero kuti Ti kapena Ta. Ti kapena Ta amakumana ndi N2 kuti apange filimu yofunikira ya TiN kapena TaN.

Pali njira zitatu zomwe zimagwiritsidwa ntchito nthawi zambiri, zomwe ndi DC sputtering, RF sputtering ndi magnetron sputtering. Pamene kuphatikizika kwa mabwalo ophatikizika kukukulirakulirabe, kuchuluka kwa zigawo zazitsulo zazitsulo zambiri zikuwonjezeka, ndipo kugwiritsa ntchito teknoloji ya PVD kukukulirakulira. Zida za PVD zikuphatikizapo Al-Si, Al-Cu, Al-Si-Cu, Ti, Ta, Co, TiN, TaN, Ni, WSi2, etc.

PVD ndi sputtering njira zambiri anamaliza mu kwambiri losindikizidwa anachita chipinda ndi zingalowe digiri 1 × 10-7 kuti 9 × 10-9 Torr, amene angathe kuonetsetsa chiyero cha mpweya pa anachita; pa nthawi yomweyo, kunja mkulu voteji chofunika ionize osowa mpweya kupanga mkulu mphamvu voteji kuti bomba chandamale. Miyezo yayikulu yowunikira PVD ndi njira zopopera ndikuphatikiza kuchuluka kwa fumbi, komanso kukana, kufanana, makulidwe owoneka bwino komanso kupsinjika kwa filimuyo.

2.2 Chemical Vapor Deposition and Sputtering Process

Chemical vapor deposition (CVD) imatanthawuza ukadaulo waukadaulo momwe ma reactants osiyanasiyana a gaseous okhala ndi kupsinjika kosiyana pang'ono amachitira ndi mankhwala pa kutentha kwina ndi kupanikizika, ndipo zinthu zolimba zomwe zimapangidwa zimayikidwa pamwamba pa gawo lapansi kuti zipeze zowonda zomwe zimafunikira. kanema. Munjira yophatikizira yophatikizika yophatikizika, zinthu zowonda zamakanema zomwe zimapezeka nthawi zambiri zimakhala zophatikiza monga ma oxides, nitrides, carbides, kapena zinthu monga polycrystalline silicon ndi amorphous silicon. Kukula kosankha epitaxial, komwe kumagwiritsidwa ntchito kwambiri pambuyo pa 45nm node, monga gwero ndi kukhetsa SiGe kapena Si selective epitaxial kukula, ndiukadaulo wa CVD.

Ukadaulo uwu ukhoza kupitiliza kupanga zida za kristalo zamtundu womwewo kapena zofananira ndi latisi yoyambirira pagawo limodzi la kristalo la silicon kapena zida zina pamlingo woyambirira. CVD imagwiritsidwa ntchito kwambiri pakukula kwa mafilimu oteteza dielectric (monga SiO2, Si3N4 ndi SiON, etc.) ndi mafilimu achitsulo (monga tungsten, etc.).

Nthawi zambiri, malinga ndi gulu la kuthamanga, CVD imatha kugawidwa mumlengalenga wothamanga Chemical vapor deposition (APCVD), sub-atmosphere pressure chemical vapor deposition (SAPCVD) ndi low pressure chemical vapor deposition (LPCVD).

Malinga ndi kutentha gulu, CVD akhoza kugawidwa mu kutentha / otsika kutentha okusayidi filimu mankhwala nthunzi deposition (HTO / LTO CVD) ndi mofulumira matenthedwe mankhwala nthunzi mafunsidwe (Rapid Thermal CVD, RTCVD);

Malinga ndi zomwe zimachitika, CVD ikhoza kugawidwa mu CVD yochokera ku silane, CVD yochokera ku polyester (TEOS-based CVD) ndi chitsulo cha organic chemical vapor deposition (MOCVD);

Malinga ndi gulu lamphamvu, CVD imatha kugawidwa kukhala matenthedwe amadzimadzi amadzimadzi (Thermal CVD), plasma yopititsa patsogolo mpweya wamankhwala (Plasma Enhanced CVD, PECVD) ndi kachulukidwe kakang'ono ka plasma chemical vapor deposition (High Density Plasma CVD, HDPCVD). Posachedwapa, ma flowable chemical vapor deposition (Flowable CVD, FCVD) okhala ndi luso lapamwamba lodzaza mipata adapangidwanso.

Makanema osiyanasiyana okulirapo a CVD ali ndi zinthu zosiyanasiyana (monga kapangidwe ka mankhwala, dielectric constant, tension, stress and breakdown voltage) ndipo atha kugwiritsidwa ntchito padera malinga ndi zofunikira zosiyanasiyana zamachitidwe (monga kutentha, kuphimba masitepe, kudzaza zofunika, ndi zina).

2.3 Njira yoyika magawo a atomiki

Atomic layer deposition (ALD) imatanthawuza kuyika kwa ma atomu osanjikiza ndi kusanjikiza pagawo laling'ono pokulitsa filimu ya atomiki imodzi ndi wosanjikiza. ALD wamba amatengera njira yolowetsa zoyambira mpweya mu riyakitala mosinthasintha pulsed.

Mwachitsanzo, choyamba, zomwe zimachitikira kalambulabwalo 1 zimalowetsedwa mu gawo lapansi, ndipo pambuyo pa kutsatsa kwamankhwala, gawo limodzi la atomiki limapangidwa pa gawo lapansi; ndiye kalambulabwalo 1 yotsalira pa gawo lapansi ndipo mu chipinda chochitiramo amapopedwa ndi mpope wa mpweya; ndiye zimene kalambulabwalo 2 umayamba mu gawo lapansi pamwamba, ndi mankhwala amachitira ndi kalambulabwalo 1 adsorbed pa gawo lapansi pamwamba kupanga lolingana woonda filimu zakuthupi ndi lolingana ndi-mankhwala pa gawo lapansi pamwamba; pamene kalambulabwalo 1 imachita kwathunthu, zomwe zimachitikazo zimatha zokha, zomwe ndizodziletsa zokha za ALD, ndiyeno zotsalira zotsalira ndi zotsalira zimachotsedwa kuti zikonzekere gawo lotsatira la kukula; mwa kubwereza ndondomeko pamwamba mosalekeza, mafunsidwe a woonda filimu zipangizo kukula wosanjikiza ndi wosanjikiza ndi maatomu limodzi chingapezeke.

Onse ALD ndi CVD ndi njira zopezera gwero la gaseous chemical reaction gwero kuti lizigwira ntchito pamtunda, koma kusiyana kwake ndikuti gwero la mpweya wa CVD lilibe mawonekedwe odziletsa kukula. Zitha kuwoneka kuti chinsinsi chopangira ukadaulo wa ALD ndikupeza zoyambira zokhala ndi zodziletsa zokha.

2.4 Njira ya Epitaxial

Njira ya Epitaxial imatanthawuza njira yokulitsa kusanjikiza kokhazikika kwa kristalo pa gawo lapansi. Nthawi zambiri, njira ya epitaxial ndiyo kukulitsa kristalo wosanjikiza womwe umakhala wofanana ndi lattice ngati gawo lapansi loyambirira pagawo limodzi la kristalo. Epitaxial process imagwiritsidwa ntchito kwambiri popanga semiconductor, monga epitaxial silicon wafers mu Integrated circuit industry, embedded source and draining epitaxial growth of MOS transistors, epitaxial growth pa LED substrates, etc.

Malingana ndi zigawo zosiyana za kukula kwa gwero, njira za kukula kwa epitaxial zikhoza kugawidwa kukhala olimba gawo epitaxy, madzi gawo epitaxy, ndi nthunzi gawo epitaxy. Pakupanga madera ophatikizika, njira zomwe zimagwiritsidwa ntchito kwambiri ndi epitaxial ndi gawo lolimba la epitaxy ndi vapor phase epitaxy.

Solid phase epitaxy: imatanthawuza kukula kwa kristalo umodzi wosanjikiza pa gawo lapansi pogwiritsa ntchito gwero lolimba. Mwachitsanzo, matenthedwe annealing pambuyo implantation ion kwenikweni ndi olimba gawo epitaxy ndondomeko. Pakuyika kwa ion, maatomu a silicon a wafer wa silicon amawomberedwa ndi ma ion opangidwa ndi mphamvu zambiri, kusiya malo awo oyambira ndikukhala amorphous, kupanga wosanjikiza wa silicon wa amorphous. Pambuyo pa kutentha kwapamwamba kwambiri, maatomu a amorphous amabwerera kumalo awo a lattice ndikukhalabe ofanana ndi momwe ma atomiki a kristalo amayendera mkati mwa gawo lapansi.

Njira zokulirapo za vapor phase epitaxy zimaphatikizapo chemical vapor phase epitaxy, molecular beam epitaxy, atomic layer epitaxy, etc. Pakupanga dera lophatikizika, mankhwala a vapor phase epitaxy ndi omwe amagwiritsidwa ntchito kwambiri. Mfundo ya mankhwala vapor phase epitaxy kwenikweni ndi yofanana ndi ya mankhwala vapor deposition. Zonsezi ndi njira zomwe zimayika mafilimu opyapyala pochita zinthu pamwamba pa zowotcha pambuyo posakanikirana ndi gasi.

Kusiyana kwake ndikwakuti chifukwa mankhwala vapor phase epitaxy amakula wosanjikiza wa kristalo umodzi, amakhala ndi zofunikira zapamwamba pazida zonyansa mu zida ndi ukhondo wa pamwamba. Njira yoyambirira ya nthunzi yamtundu wa epitaxial silicon iyenera kuchitika pansi pa kutentha kwambiri (kuposa 1000 ° C). Ndi kusintha kwa zipangizo zamakono, makamaka kukhazikitsidwa kwa teknoloji ya chipinda chosinthira vacuum, ukhondo wa zida zopangira zida ndi pamwamba pa nsalu ya silicon wakhala bwino kwambiri, ndipo silicon epitaxy ikhoza kuchitidwa pa kutentha kochepa (600-700 °). C). Njira ya epitaxial silicon wafer ndikukulitsa wosanjikiza wa silicon imodzi ya crystal pamwamba pa silicon wafer.

Poyerekeza ndi gawo lapansi loyambirira la silicon, wosanjikiza wa silicon wa epitaxial uli ndi chiyero chapamwamba komanso zolakwika zochepa za lattice, potero zimakulitsa zokolola zamapangidwe a semiconductor. Kuphatikiza apo, makulidwe a kukula ndi kuchuluka kwa doping kwa wosanjikiza wa silicon wa epitaxial womwe wakula pa silicon wafer amatha kupangidwa mosinthika, zomwe zimabweretsa kusinthasintha pamapangidwe a chipangizocho, monga kuchepetsa kukana kwa gawo lapansi komanso kukulitsa kudzipatula kwa gawo lapansi. Njira yophatikizika ya epitaxial source-drain ndi ukadaulo womwe umagwiritsidwa ntchito kwambiri pama node apamwamba aukadaulo.

Zimatanthawuza njira yokulitsa epitaxially doped germanium silicon kapena silicon komwe kumayambira ndi kukhetsa zigawo za transistors za MOS. Ubwino waukulu woyambitsa njira yophatikizika ya epitaxial source-drain ndi: kukula kwa pseudocrystalline wosanjikiza wokhala ndi nkhawa chifukwa cha kusintha kwa lattice, kuwongolera kuyenda kwa chonyamulira; in-situ doping ya gwero ndi kukhetsa kungachepetse kukana kwa parasitic pamphambano ya source-drain ndikuchepetsa kuwonongeka kwa implantation yamphamvu ya ion.

3. woonda filimu kukula zida

3.1 Zida zotulutsa mpweya

Vacuum evaporation ndi njira yophikira yomwe imatenthetsa zinthu zolimba m'chipinda cha vacuum kuti zisungunuke, zisungunuke kapena zisasunthike, kenako ndikumangirira ndikuyika pamwamba pa gawo lapansi pa kutentha kwina.

Kawirikawiri imakhala ndi magawo atatu, omwe ndi vacuum system, evaporation system ndi kutentha. Dongosolo la vacuum lili ndi mapaipi a vacuum ndi mapampu a vacuum, ndipo ntchito yake yayikulu ndikupereka malo oyenera opulumutsira mpweya. Dongosolo la evaporation lili ndi tebulo la evaporation, gawo lotenthetsera ndi gawo loyezera kutentha.

Zomwe mukufuna kuti zisungunuke (monga Ag, Al, etc.) zimayikidwa patebulo la evaporation; chigawo choyezera kutentha ndi kutentha ndi njira yotsekedwa yotsekedwa yomwe imagwiritsidwa ntchito poyang'anira kutentha kwa evaporation kuti zitsimikizidwe kuti zisamawonongeke. Makina otenthetsera amakhala ndi siteji yowotchera komanso gawo lotenthetsera. Gawo lawafali limagwiritsidwa ntchito kuyika gawo lapansi pomwe filimu yopyapyala imayenera kutenthedwa, ndipo gawo lotenthetsera limagwiritsidwa ntchito kuzindikira kutentha kwa gawo lapansi ndi kuwongolera kutentha kwa mayankho.

Chilengedwe cha vacuum ndi chofunikira kwambiri pamayendedwe a vacuum evaporation, omwe amagwirizana ndi kuchuluka kwa evaporation komanso mtundu wa filimuyo. Ngati vacuum digiri si kukwaniritsa zofunika, ndi vaporized maatomu kapena mamolekyu adzawombana kawirikawiri ndi mamolekyu otsala mpweya, kupanga njira yawo ufulu ang'onoang'ono, ndi maatomu kapena mamolekyu adzabalalika kwambiri, potero kusintha mayendedwe ndi kuchepetsa filimu. mlingo wa mapangidwe.

Kuonjezera apo, chifukwa cha kukhalapo kwa mamolekyu otsalira a gasi osadetsedwa, filimu yosungidwayo imakhala yoipitsidwa kwambiri komanso yopanda khalidwe, makamaka pamene kuthamanga kwa chipindacho sikukugwirizana ndi muyezo ndipo pali kutayikira, mpweya udzalowa mu chipinda chopuma. , zomwe zidzakhudza kwambiri khalidwe la filimuyi.

Mawonekedwe a zida za vacuum evaporation amatsimikizira kuti kufananiza kwa zokutira pazigawo zazikuluzikulu ndizosauka. Pofuna kupititsa patsogolo kufanana kwake, njira yowonjezerera mtunda wa gwero ndi kuzungulira gawo lapansi nthawi zambiri imatengedwa, koma kuwonjezera mtunda wa gwero-gawo laling'ono lidzapereka kukula ndi chiyero cha filimuyo. Pa nthawi yomweyi, chifukwa cha kuwonjezeka kwa malo otsekemera, kugwiritsa ntchito zinthu zowonongeka kumachepetsedwa.

3.2 DC zida zoyika mpweya

Direct current physical vapor deposition (DCPVD) imadziwikanso kuti cathode sputtering kapena vacuum DC two-stage sputtering. Zolinga za vacuum DC sputtering zimagwiritsidwa ntchito ngati cathode ndipo gawo lapansi limagwiritsidwa ntchito ngati anode. Vacuum sputtering ndi kupanga madzi a m'magazi ndi ionizing gasi.

The particles mlandu mu plasma imathandizira m'munda wamagetsi kuti apeze mphamvu zina. The particles ndi mphamvu zokwanira kuphulitsa pamwamba pa chandamale zakuthupi, kotero kuti chandamale maatomu ndi spttered kunja; maatomu otayidwa ndi mphamvu inayake ya kinetic amasunthira ku gawo lapansi kupanga filimu yopyapyala pamwamba pa gawo lapansi. Mpweya womwe umagwiritsidwa ntchito popopera nthawi zambiri ndi mpweya wosowa, monga argon (Ar), kotero kuti filimu yopangidwa ndi sputtering sichidzaipitsidwa; kuonjezera apo, utali wa atomiki wa argon ndiwoyenera kutulutsa.

Kukula kwa particles sputtering ayenera kukhala pafupi ndi kukula kwa chandamale maatomu kuti sputtered. Ngati tinthu tating'onoting'ono tating'ono kapena tating'ono, sputtering yogwira mtima siyingapangidwe. Kuphatikiza pa kukula kwa atomu, kuchuluka kwa atomu kumakhudzanso mtundu wa sputtering. Ngati sputtering tinthu gwero ndi kuwala kwambiri, chandamale maatomu sadzakhala sputtered; ngati particles sputtering ndi olemera kwambiri, chandamale adzakhala "wopindika" ndipo chandamale si spttered.

Zomwe zimagwiritsidwa ntchito mu DCPVD ziyenera kukhala kondakitala. Izi ndichifukwa choti ma argon ions munjira ya gasi aphulitsa chandamale, amalumikizananso ndi ma elekitironi pamwamba pa zomwe akufuna. Pamene chandamale chandamale ndi kondakita monga chitsulo, ma elekitironi kudyedwa ndi recombination izi mosavuta replenited ndi magetsi ndi ma elekitironi ufulu mbali zina za chandamale zinthu kudzera conduction magetsi, kotero kuti pamwamba pa chandamale zinthu monga lonse amakhalabe zoipa mlandu ndi sputtering anakhalabe.

M'malo mwake, ngati chandamale ndi insulator, pambuyo poti ma elekitironi omwe ali pamwamba pa zinthu zomwe akufuna kubwerezedwa, ma elekitironi aulere omwe ali m'malo ena azinthu zomwe akuwunikira sangathe kuwonjezeredwa ndi ma conduction amagetsi, ndipo ngakhale zolipiritsa zabwino zimadziunjikira pa. pamwamba pa zinthu zomwe chandamalezo, zomwe zimapangitsa kuti zinthu zomwe mukufuna zitheke kukwera, ndipo chiwongoladzanja choyipa cha chinthucho chimafowoka mpaka chizimiririka, ndipo pamapeto pake zimayambitsa kutha kwa sputtering.

Chifukwa chake, kuti mupange zida zoziziritsa kukhosi zomwe zingagwiritsidwenso ntchito pakupopera, ndikofunikira kupeza njira ina yothirira. Kupopera pafupipafupi kwa wailesi ndi njira yolankhulirana yomwe ili yoyenera pazolinga zonse zowongolera komanso zosagwirizana.

Kuipa kwina kwa DCPVD ndikuti mphamvu yoyatsira ndi yokwera ndipo bombardment ya ma elekitironi pa gawo lapansi ndi yamphamvu. Njira yabwino yothetsera vutoli ndikugwiritsa ntchito magnetron sputtering, kotero kuti magnetron sputtering ndi yothandiza kwambiri pamagulu ophatikizana.

3.3 RF Physical Vapor Deposition Equipment

Radio frequency physical vapor deposition (RFPVD) imagwiritsa ntchito mphamvu ya mawayilesi ngati gwero lachisangalalo ndipo ndi njira ya PVD yoyenera zitsulo zosiyanasiyana komanso zosapanga zitsulo.

Mafupipafupi amagetsi a RF omwe amagwiritsidwa ntchito mu RFPVD ndi 13.56MHz, 20MHz, ndi 60MHz. Mayendedwe abwino ndi oyipa amagetsi a RF amawonekera mosinthana. Pamene PVD chandamale ndi zabwino theka mkombero, chifukwa chandamale pamwamba ndi pa kuthekera zabwino, ma elekitironi mu ndondomeko mlengalenga adzayenderera kwa chandamale pamwamba kuti neutralize mlandu zabwino anasonkhanitsa padziko, ndipo ngakhale kupitiriza kudziunjikira ma elekitironi, kupangitsa kuti nkhope yake ikhale yosakondera; pamene chandamale cha sputtering chiri mu theka loipa, ma ion abwino amasunthira ku chandamalecho ndikukhala opanda mphamvu pa chandamalecho.

Chofunikira kwambiri ndichakuti kuthamanga kwa ma elekitironi mu gawo lamagetsi la RF ndikothamanga kwambiri kuposa ma ion abwino, pomwe nthawi yamayendedwe abwino ndi oyipa ndi ofanana, ndiye kuti pakatha kuzungulira kwathunthu, malo omwe akuwafunawo amakhala. "ukonde" woyimbidwa molakwika. Chifukwa chake, m'mizere ingapo yoyamba, chiwongolero choyipa cha malo omwe chandamale chikuwonetsa kuchulukirachulukira; pambuyo pake, chandamale pamwamba amafika khola zoipa kuthekera; pambuyo pake, chifukwa chandamale yoyipa ya chandamale imakhala ndi zotsatira zonyansa pa ma elekitironi, kuchuluka kwa zolipiritsa zabwino ndi zoyipa zomwe zimalandilidwa ndi chandamale cha electrode zimayendera bwino, ndipo chandamale chimapereka chiwopsezo chokhazikika.

Kuchokera pamwamba pa ndondomekoyi, zikhoza kuwoneka kuti ndondomeko ya mapangidwe oipa amagetsi alibe chochita ndi katundu wa zinthu zomwe akufuna, kotero njira ya RFPVD sichitha kuthetsa vuto la sputtering ya zolinga zotetezera, komanso zimagwirizana bwino. ndi mipherezero wamba zitsulo conductor.

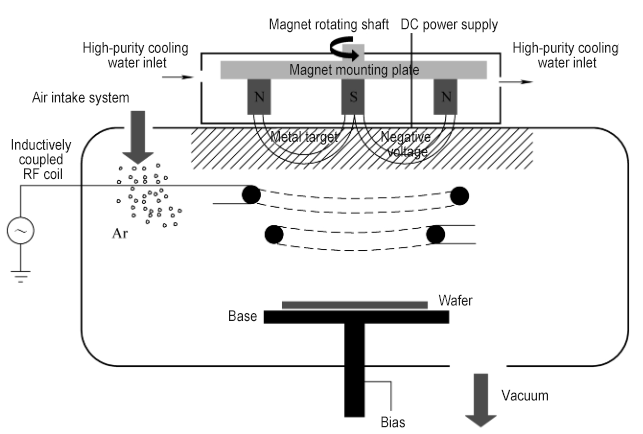

3.4 Zida za Magnetron sputtering

Magnetron sputtering ndi njira ya PVD yomwe imawonjezera maginito kumbuyo kwa chandamale. Maginito owonjezera ndi magetsi a DC (kapena magetsi a AC) amapanga gwero la magnetron sputtering. Gwero la sputtering limagwiritsidwa ntchito kupanga gawo lolumikizana lamagetsi m'chipindamo, kujambula ndi kuchepetsa kusuntha kwa ma elekitironi mu plasma mkati mwa chipindacho, kukulitsa njira yoyendetsera ma elekitironi, motero kumawonjezera kuchuluka kwa plasma, ndikukwaniritsa zambiri. kuika.

Kuonjezera apo, chifukwa ma electron ambiri amamangidwa pafupi ndi pamwamba pa chandamale, kuphulika kwa gawo lapansi ndi ma electron kumachepetsedwa, ndipo kutentha kwa gawo lapansi kumachepetsedwa. Poyerekeza ndi luso lathyathyathya mbale DCPVD, chimodzi mwa zinthu zoonekeratu za magnetron thupi nthunzi mafunsidwe luso ndi kuti poyatsira kumaliseche voteji ndi m'munsi ndi khola.

Chifukwa cha kuchuluka kwake kwa plasma komanso kutulutsa kwake kokulirapo, imatha kuchita bwino kwambiri pakuyika, kuwongolera makulidwe amtundu waukulu, kuwongolera koyenera komanso mphamvu yotsika yoyatsira. Choncho, magnetron sputtering ali ndi udindo waukulu mu filimu panopa zitsulo PVD. The losavuta magnetron sputtering gwero kapangidwe ndi kuika gulu la maginito kumbuyo kwa chandamale lathyathyathya (kunja kwa vacuum dongosolo) kupanga maginito munda kufanana ndi chandamale pamwamba m'dera m'dera chandamale pamwamba.

Ngati maginito okhazikika ayikidwa, mphamvu yake ya maginito imakhala yosasunthika, zomwe zimapangitsa kuti maginito agawidwe mokhazikika pa malo omwe akuwongolera m'chipindamo. Zida zokhazokha zomwe zili m'madera enieni a chandamale zimaphwanyidwa, chiwerengero chogwiritsira ntchito chandamale ndi chochepa, ndipo kufanana kwa filimu yokonzekera kumakhala kovuta.

Pali Mwina kuti sputtered zitsulo kapena zinthu particles adzakhala waikamo mmbuyo pa chandamale pamwamba, potero aggregating mu particles ndi kupanga chilema kuipitsidwa. Chifukwa chake, magwero a magnetron sputtering amalonda nthawi zambiri amagwiritsa ntchito kapangidwe ka maginito kozungulira kuti apititse patsogolo kufanana kwa filimu, kugwiritsira ntchito chandamale, komanso kutulutsa chandamale chonse.

Ndikofunikira kulinganiza zinthu zitatuzi. Ngati ndalamazo sizikuyendetsedwa bwino, zitha kupangitsa kuti filimuyo ikhale yofanana ndikuchepetsa kwambiri zomwe mukufuna kugwiritsa ntchito (kufupikitsa moyo womwe mukufuna), kapena kulephera kukwaniritsa chiwopsezo chonse kapena dzimbiri lathunthu, zomwe zingayambitse vuto la tinthu panthawi ya sputtering. ndondomeko.

Mu luso magnetron PVD, m'pofunika kuganizira kasinthasintha maginito kayendedwe limagwirira, chandamale mawonekedwe, chandamale kuzirala dongosolo ndi gwero magnetron sputtering, komanso kasinthidwe zinchito m'munsi kuti amanyamula yopyapyala, monga yopyapyala adsorption ndi kulamulira kutentha. Mu ndondomeko ya PVD, kutentha kwa chofufumitsa kumayendetsedwa kuti mupeze mawonekedwe a kristalo, kukula kwa tirigu ndi maonekedwe, komanso kukhazikika kwa ntchito.

Popeza kutentha kwapakati pa kumbuyo kwa chowotcha ndi pamwamba pa m'munsi kumafuna kupanikizika kwina, kawirikawiri mu dongosolo la Torr angapo, ndipo kupanikizika kwa chipinda kumakhala mu dongosolo la mTorr angapo, kupanikizika kumbuyo. Chophikacho chimakhala chokulirapo kuposa kukakamiza pamwamba pa chowotchacho, kotero kuti chuck yamakina kapena chuck ya electrostatic ndiyofunika kuyiyika ndikuchepetsa chophatikiziracho.

Makina chuck amadalira kulemera kwake komanso m'mphepete mwa chofufumitsa kuti akwaniritse ntchitoyi. Ngakhale kuti ili ndi ubwino wa mapangidwe osavuta komanso osakhudzidwa ndi zinthu zamtengo wapatali, zotsatira za m'mphepete mwa mtandawo ndizodziwikiratu, zomwe sizikugwirizana ndi kulamulira mwamphamvu kwa tinthu tating'onoting'ono. Chifukwa chake, idasinthidwa pang'onopang'ono ndi chuck electrostatic mukupanga IC.

Pazinthu zomwe sizimakhudzidwa kwambiri ndi kutentha, njira yopanda adsorption, yopanda m'mphepete yolumikizana ndi shelving (palibe kusiyana pakati pa malo apamwamba ndi otsika) angagwiritsidwenso ntchito. Panthawi ya PVD, chipinda cha chipinda ndi pamwamba pa zigawo zomwe zimagwirizana ndi plasma zidzayikidwa ndikuphimba. Pamene makulidwe a filimu yoyikidwayo adutsa malire, filimuyo imasweka ndikusweka, zomwe zimayambitsa mavuto.

Choncho, mankhwala pamwamba mbali monga akalowa ndi chinsinsi kuwonjezera malire. Kupaka mchenga pamwamba ndi kupopera zitsulo zotayidwa ndi njira ziwiri zomwe zimagwiritsidwa ntchito, zomwe cholinga chake ndi kuonjezera roughness pamwamba kuti kulimbikitsa mgwirizano pakati pa filimu ndi akalowa pamwamba.

3.5 Ionization Physical Vapor Deposition Equipment

Ndikukula kosalekeza kwaukadaulo wa ma microelectronics, kukula kwa mawonekedwe akucheperachepera. Popeza ukadaulo wa PVD sungathe kuwongolera momwe timadulira tinthu tating'onoting'ono, kuthekera kwa PVD kulowa m'mabowo ndi mayendedwe opapatiza okhala ndi mawonekedwe apamwamba kumakhala kochepa, zomwe zimapangitsa kuti kugwiritsa ntchito ukadaulo wachikhalidwe cha PVD kuvutike. Mu ndondomeko ya PVD, pamene chiŵerengero cha pore groove chikuwonjezeka, kuphimba pansi kumachepa, kupanga mawonekedwe ozungulira ngati mapiko pamwamba pa ngodya, ndikupanga kuphimba kofooka kwambiri pansi pa ngodya.

Tekinoloje ya ionized vapor deposition idapangidwa kuti ithetse vutoli. Choyamba plasmatizes zitsulo maatomu sputtered kuchokera chandamale m'njira zosiyanasiyana, ndiyeno kusintha kukondera voteji yodzaza pa mtanda kulamulira malangizo ndi mphamvu ya ayoni zitsulo kupeza khola directional zitsulo ion otaya kukonzekera filimu woonda, potero kuwongolera Kuphimba pansi pa masitepe a chiŵerengero chapamwamba kudzera m'mabowo ndi njira zopapatiza.

Chodziwika bwino chaukadaulo wa ionized metal plasma ndikuwonjezera kwa ma radio frequency coil muchipinda. Panthawiyi, kupanikizika kwa chipindacho kumasungidwa pamalo apamwamba (nthawi 5 mpaka 10 nthawi zonse). Pa PVD, ma radio frequency coil amagwiritsidwa ntchito popanga gawo lachiwiri la plasma, momwe ndende ya argon plasma imachulukira ndikuwonjezera mphamvu yamagetsi yamagetsi ndi kupanikizika kwa gasi. Pamene maatomu achitsulo omwe amatuluka kuchokera ku chandamale amadutsa m'derali, amalumikizana ndi argon plasma wochuluka kwambiri kuti apange ayoni achitsulo.

Kuyika gwero la RF pa chonyamulira chophatikizira (monga chotengera cha electrostatic) kumatha kukulitsa tsankho loyipa pa chophatikiziracho kukopa ma ion abwino achitsulo pansi pa pore pore. Izi molunjika zitsulo ion kuyenda perpendicular pamwamba yopyapyala pamwamba bwino sitepe Kuphunzira mkulu mbali chiŵerengero pores ndi yopapatiza njira.

Kukondera koyipa komwe kumagwiritsidwa ntchito pamtengowo kumapangitsanso kuti ma ion aziwombera pamwamba pamiyala (reverse sputtering), zomwe zimafooketsa mawonekedwe a pore groove pakamwa ndikutulutsa filimuyo pansi pamakona apansi pa pore. groove, potero kukulitsa kufalikira kwa masitepe pamakona.

3.6 Atmospheric Pressure Chemical Vapor Deposition Equipment

Chida cha Atmospheric pressure chemical vapor deposition (APCVD) chimatanthawuza chipangizo chomwe chimapopera gwero la mpweya ndi liwiro mosalekeza pamwamba pa gawo lapansi lotentha kwambiri pansi pa chilengedwe ndi kupanikizika kwapafupi ndi kupanikizika kwa mumlengalenga, zomwe zimapangitsa kuti gwero lizigwira ntchito ndi mankhwala. gawo lapansi pamwamba, ndi zomwe mankhwala waikamo pa gawo lapansi pamwamba kupanga woonda filimu.

Zida za APCVD ndizo zida zoyambirira za CVD ndipo zimagwiritsidwabe ntchito kwambiri popanga mafakitale ndi kafukufuku wasayansi. Zida za APCVD zingagwiritsidwe ntchito pokonzekera mafilimu oonda monga crystal silicon, polycrystalline silicon, silicon dioxide, zinc oxide, titanium dioxide, galasi la phosphosilicate, ndi galasi la borophosphosilicate.

3.7 Low Pressure Chemical Vapor Deposition Equipment

Zida za Low-pressure chemical vapor deposition (LPCVD) zimatanthawuza zida zomwe zimagwiritsa ntchito zinthu zopangira mpweya kuti zigwirizane ndi mankhwala pamtunda wa gawo lapansi lolimba pansi pa kutentha (350-1100 ° C) ndi malo otsika (10-100mTorr), ndi ma reactants amayikidwa pa gawo lapansi kuti apange filimu yopyapyala. Zipangizo za LPCVD zimapangidwira pamaziko a APCVD kuti apititse patsogolo mafilimu opyapyala, kusintha kugawa kufanana kwa magawo monga filimuyo makulidwe ndi resistivity, ndi kupititsa patsogolo kupanga.

Mbali yake yaikulu ndi yakuti m'malo otsika kwambiri otentha, mpweya umakhudzidwa ndi mankhwala pamwamba pa gawo lapansi, ndipo zomwe zimapangidwira zimayikidwa pamtunda kuti apange filimu yopyapyala. Zipangizo za LPCVD zili ndi ubwino pokonza mafilimu oonda kwambiri ndipo zingagwiritsidwe ntchito pokonzekera mafilimu oonda monga silicon oxide, silicon nitride, polysilicon, silicon carbide, gallium nitride ndi graphene.

Poyerekeza ndi APCVD, otsika-anzanu anachita chilengedwe cha LPCVD zipangizo kumawonjezera zikutanthauza ufulu njira ndi mayamwidwe coefficient wa mpweya mu chipinda anachita.

Zimene mpweya ndi chonyamulira mpweya mamolekyulu mu anachita chipinda akhoza wogawana anagawira mu nthawi yochepa, motero kwambiri kuwongolera kufanana kwa filimu makulidwe, resistivity kufanana ndi sitepe Kuphunzira filimu, ndi kumwa anachita mpweya ndi yaing'ono. Kuonjezera apo, malo otsika kwambiri amafulumizitsanso kuthamanga kwa zinthu za gasi. Zonyansa ndi zochita ndi-mankhwala diffused ku gawo lapansi akhoza mwamsanga kuchotsedwa anachita zone kupyolera malire wosanjikiza, ndi zimene mpweya mwamsanga kudutsa malire wosanjikiza kufika gawo lapansi pamwamba anachita, motero mogwira kupondereza kudziletsa doping, kukonzekera. mafilimu apamwamba kwambiri okhala ndi madera otsetsereka, komanso kupititsa patsogolo kupanga bwino.

3.8 Chida Chowonjezera cha Ma Chemical Vapor Deposition Plasma

Plasma enhanced chemical vapor deposition (PECVD) ndi njira yomwe imagwiritsidwa ntchito kwambiriHin film deposition technology. Pa plasma ndondomeko, mpweya kalambulabwalo ndi ionized pansi pa zochita za madzi a m'magazi kupanga osangalala yogwira magulu, amene diffus kuti gawo lapansi pamwamba kenako amakumana zimachitikira mankhwala kumaliza filimu kukula.

Malinga ndi kuchuluka kwa plasma m'badwo, plasma yomwe imagwiritsidwa ntchito mu PECVD imatha kugawidwa m'mitundu iwiri: radio frequency plasma (RF plasma) ndi microwave plasma (Microwave plasma). Pakalipano, mawailesi omwe amagwiritsidwa ntchito pamakampani nthawi zambiri amakhala 13.56MHz.

Kuyambitsa ma radio frequency plasma nthawi zambiri amagawidwa m'mitundu iwiri: capacitive coupling (CCP) ndi inductive coupling (ICP). The capacitive coupling njira kawirikawiri mwachindunji plasma reaction njira; pamene njira yolumikizira inductive ingakhale njira yolunjika ya plasma kapena njira yakutali ya plasma.

M'njira zopangira semiconductor, PECVD imagwiritsidwa ntchito nthawi zambiri kukulitsa mafilimu opyapyala pamagawo okhala ndi zitsulo kapena zinthu zina zotengera kutentha. Mwachitsanzo, m'munda wa kulumikiza zitsulo kumbuyo kwa mabwalo ophatikizika, popeza gwero, chipata ndi zida zokhetsera zida zakhazikitsidwa kutsogolo, kukula kwa mafilimu oonda m'munda wa kulumikizana kwazitsulo kumayendetsedwa. ku zovuta kwambiri za bajeti yamafuta, motero zimamalizidwa ndi chithandizo cha plasma. Mwa kusintha magawo a ndondomeko ya plasma, kachulukidwe, kapangidwe ka mankhwala, zonyansa, kulimba kwa makina ndi kupanikizika kwa filimu yopyapyala yomwe imakula ndi PECVD ikhoza kusinthidwa ndikukonzedwanso mkati mwazosiyana.

3.9 Zida Zoyika Ma Atomiki

Atomic layer deposition (ALD) ndi ukadaulo wocheperako woyika filimu womwe umakula nthawi ndi nthawi ngati gawo la quasi-monoatomic layer. Makhalidwe ake ndikuti makulidwe a filimu yoyikidwayo amatha kusinthidwa bwino ndikuwongolera kuchuluka kwa kakulidwe. Mosiyana ndi ndondomeko ya mankhwala a vapor deposition (CVD), zotsogola ziwiri (kapena kupitilira apo) mu njira ya ALD zimadutsa pamtunda wapansi panthaka ndipo zimasiyanitsidwa bwino ndi kuchotsedwa kwa gasi wosowa.

Ma precursors awiriwa sangasakanizike ndikukumana mu gawo la gasi kuti achitepo kanthu, koma amangochita ndi kutsatsa kwamankhwala pamtunda wapansi panthaka. Pachizunguliro chilichonse cha ALD, kuchuluka kwa precursor adsorbed pamtunda wa gawo lapansi kumakhudzana ndi kuchuluka kwa magulu omwe akugwira nawo gawo lapansi. Pamene magulu ochitapo kanthu pamtunda wa gawo lapansi atha, ngakhale kuwonjezereka kwa kalambulabwalo kumayambika, kutsatsa kwa mankhwala sikudzachitika pa gawo lapansi.

Kachitidwe kameneka kameneka kamatchedwa kuti pamwamba paokha. Kachitidwe kameneka kamapangitsa kuti makulidwe a filimuyo akule mumkombero uliwonse wa njira ya ALD mosalekeza, kotero kuti njira ya ALD ili ndi ubwino wowongolera makulidwe ake komanso kufalikira kwamayendedwe afilimu.

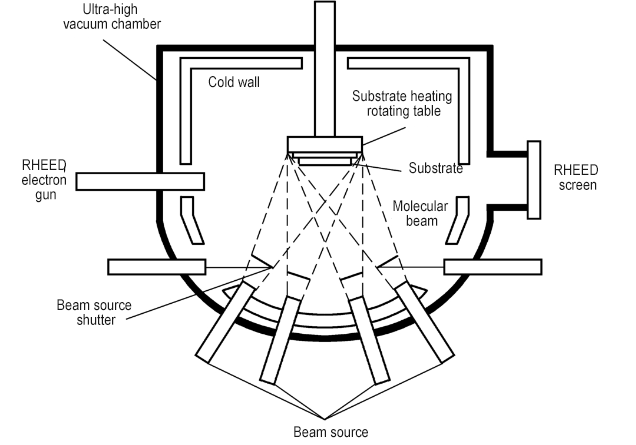

3.10 Zida za Molecular Beam Epitaxy

Dongosolo la Molecular Beam Epitaxy (MBE) limatanthawuza chipangizo cha epitaxial chomwe chimagwiritsa ntchito nthiti imodzi kapena zingapo zotentha za atomiki kapena ma molekyulu kuti zipopera pagawo lotentha la gawo lapansi pa liwiro linalake pansi pa mikhalidwe ya vacuum yapamwamba kwambiri, ndikumangirira ndi kusamuka pamtunda wapansi panthaka. kukulitsa epitaxially filimu yopyapyala yamtundu umodzi motsatira njira ya crystal axis ya gawo lapansi. Nthawi zambiri, pansi pa kutentha kwa ng'anjo ya jet yokhala ndi chishango cha kutentha, gwero la mtengowo limapanga mtengo wa atomiki kapena mtengo wa molekyulu, ndipo filimuyo imakula mosanjikiza ndi wosanjikiza motsatira njira ya crystal axis ya gawo lapansi.

Makhalidwe ake ndi otsika kutentha kwa epitaxial kukula, ndipo makulidwe, mawonekedwe, kapangidwe ka mankhwala ndi ndende yonyansa imatha kuyendetsedwa bwino pamlingo wa atomiki. Ngakhale kuti MBE inachokera pokonzekera mafilimu a semiconductor ultra-thin single crystal, ntchito yake tsopano yakula kuzinthu zosiyanasiyana monga zitsulo ndi ma dielectrics otetezera, ndipo akhoza kukonzekera III-V, II-VI, silicon, silicon germanium (SiGe). ), graphene, oxides ndi mafilimu organic.

Dongosolo la molecular beam epitaxy (MBE) limapangidwa makamaka ndi ultra-high vacuum system, gwero la molekyulu ya molekyulu, makina owongolera ndi kutentha, makina osinthira zitsanzo, makina owunikira, makina owongolera, ndi mayeso. dongosolo.

Dongosolo la vacuum limaphatikizapo mapampu a vacuum (mapampu amakina, mapampu a molekyulu, mapampu a ion, mapampu a condensation, etc.) ndi ma valve osiyanasiyana, omwe amatha kupanga malo okulirapo kwambiri. Digiri ya vacuum yomwe imapezeka nthawi zambiri ndi 10-8 mpaka 10-11 Torr. Dongosolo la vacuum limakhala ndi zipinda zitatu zogwirira ntchito, zomwe ndi chipinda chojambulira chitsanzo, chipinda chothandizira komanso chowunikira pamwamba, ndi chipinda chokulirapo.

Chipinda chojambulira chachitsanzo chimagwiritsidwa ntchito kusamutsa zitsanzo kupita kudziko lakunja kuti zitsimikizire kuti zipinda zina zimakhala ndi vacuum yapamwamba; The pretreatment and surface analysis room imagwirizanitsa chipinda chojambulira chitsanzo ndi chipinda chokulirapo, ndipo ntchito yake yaikulu ndikukonzeratu chitsanzo (kutentha kwambiri kutentha kuti muwonetsetse ukhondo wa gawo lapansi) ndikuyesa kusanthula koyambirira chitsanzo choyeretsedwa; Chipinda chokulirapo ndiye gawo lalikulu la dongosolo la MBE, lomwe limapangidwa makamaka ndi ng'anjo yoyambira ndi chotsekera chake cholumikizirana, cholumikizira chowongolera, chozizira, chiwonetsero champhamvu cha electron diffraction (RHEED), ndi in-situ monitoring system. . Zida zina za MBE zopanga zimakhala ndi masinthidwe angapo a chipinda chokulirapo. Chithunzi chojambula cha zida za MBE chikuwonetsedwa pansipa:

MBE ya zinthu za silicon imagwiritsa ntchito silicon yoyera kwambiri ngati zopangira, imamera pansi pa ultra-high vacuum (10-10~10-11Torr) mikhalidwe, ndi kutentha kwa kukula ndi 600℃ 900℃, ndi Ga (P-mtundu) ndi Sb ( N-mtundu) monga magwero a doping. Zomwe zimagwiritsidwa ntchito popanga doping monga P, As ndi B sizimagwiritsidwa ntchito nthawi zambiri ngati magwero a mtengo chifukwa zimakhala zovuta kusuntha.

The anachita chipinda cha MBE ali kopitilira muyeso vacuum chilengedwe, amene kumawonjezera zikutanthauza ufulu njira mamolekyu ndi amachepetsa kuipitsidwa ndi makutidwe ndi okosijeni padziko kukula zakuthupi. Zinthu za epitaxial zomwe zakonzedwa zimakhala ndi mawonekedwe abwino komanso ofanana, ndipo zimatha kupangidwa kukhala ma multilayer okhala ndi ma doping osiyanasiyana kapena zida zosiyanasiyana.

Ukadaulo wa MBE umakwaniritsa kukula mobwerezabwereza kwa zigawo zowonda kwambiri za epitaxial ndi makulidwe a gawo limodzi la atomiki, ndipo mawonekedwe pakati pa zigawo za epitaxial ndi otsetsereka. Imalimbikitsa kukula kwa ma semiconductors a III-V ndi zinthu zina zamitundu yambiri. Pakalipano, dongosolo la MBE lakhala chida chapamwamba chopangira makina atsopano a ma microwave ndi zipangizo za optoelectronic. The kuipa MBE luso ndi pang'onopang'ono filimu kukula mlingo, mkulu vacuum zofunika, ndi mkulu zida ndi zipangizo ntchito ndalama.

3.11 Vapor Phase Epitaxy System

Dongosolo la vapor phase epitaxy (VPE) limatanthawuza chipangizo cha kukula kwa epitaxial chomwe chimatengera zinthu za gaseous kupita ku gawo lapansi ndikupeza gawo limodzi la kristalo lomwe lili ndi dongosolo lofanana la lattice monga gawo lapansi kudzera muzochita zamankhwala. Epitaxial layer ikhoza kukhala homoepitaxial layer (Si/Si) kapena heteroepitaxial layer (SiGe/Si, SiC/Si, GaN/Al2O3, etc.). Pakalipano, teknoloji ya VPE yakhala ikugwiritsidwa ntchito kwambiri pokonzekera nanomaterial, zipangizo zamagetsi, zipangizo za semiconductor optoelectronic, solar photovoltaics, ndi maulendo ophatikizika.

VPE yodziwika bwino imaphatikizapo kuthamanga kwa mpweya wa epitaxy ndi kuchepetsa kuthamanga kwa epitaxy, ultra-high vacuum vacuum chemical deposition, metal organic chemical vapor deposition, etc. Mfundo zazikuluzikulu mu teknoloji ya VPE ndi kapangidwe ka chipinda, mawonekedwe a mpweya ndi kufanana, kufanana kwa kutentha ndi kuwongolera molondola, kulamulira kuthamanga ndi kukhazikika, tinthu ndi chilema kulamulira, etc.

Pakalipano, kachitidwe kachitukuko ka machitidwe akuluakulu a malonda a VPE ndikutsegula kwakukulu, kuwongolera kwathunthu, ndi kuyang'anira nthawi yeniyeni ya kutentha ndi kukula. Machitidwe a VPE ali ndi zigawo zitatu: ofukula, yopingasa ndi cylindrical. Njira zowotchera zimaphatikizira kutenthetsa kukaniza, kutentha kwapang'onopang'ono komanso kutentha kwa ma infrared radiation.

Pakalipano, machitidwe a VPE amagwiritsa ntchito kwambiri ma disc opingasa, omwe ali ndi makhalidwe ofanana a kukula kwa filimu ya epitaxial ndi kukweza kwakukulu kwa katumbu. Makina a VPE nthawi zambiri amakhala ndi magawo anayi: riyakitala, makina otenthetsera, njira yamagesi ndi dongosolo lowongolera. Chifukwa nthawi ya kukula kwa mafilimu a GaAs ndi GaN epitaxial ndi yaitali, kutentha kwa induction ndi kutentha kwamphamvu kumagwiritsidwa ntchito kwambiri. Mu silicon VPE, kukula kwa filimu ya epitaxial nthawi zambiri kumagwiritsa ntchito kutentha kwapadera; Kukula kwa filimu yowonda kwambiri ya epitaxial nthawi zambiri kumagwiritsa ntchito kutentha kwa infrared kuti akwaniritse cholinga cha kukwera/kutsika mwachangu.

3.12 Liquid Phase Epitaxy System

Dongosolo la Liquid Phase Epitaxy (LPE) limatanthawuza zida za kukula kwa epitaxial zomwe zimasungunula zinthu kuti zikule (monga Si, Ga, As, Al, etc.) ndi ma dopants (monga Zn, Te, Sn, etc.) chitsulo chokhala ndi malo otsika osungunuka (monga Ga, In, etc.), kotero kuti solute imakhala yodzaza kapena yowonjezereka mu zosungunulira, ndiyeno gawo limodzi la kristalo ndi kulumikizidwa ndi yankho, ndipo solute imawomberedwa kuchokera ku zosungunulira pang'onopang'ono kuzirala pansi, ndipo wosanjikiza wa zinthu za kristalo wokhala ndi mawonekedwe a kristalo ndi lattice yokhazikika yofanana ndi gawo lapansi limakula pamwamba pa gawo lapansi.

Njira ya LPE idaperekedwa ndi Nelson et al. mu 1963. Amagwiritsidwa ntchito kukulitsa mafilimu a Si woonda ndi zipangizo za kristalo imodzi, komanso zipangizo za semiconductor monga magulu a III-IV ndi mercury cadmium telluride, ndipo angagwiritsidwe ntchito kupanga zipangizo zosiyanasiyana za optoelectronic, zipangizo za microwave, zipangizo za semiconductor ndi maselo a dzuwa. .

—————————————————————————————————————————————————— ————————————-

Semicera ikhoza kuperekazigawo za graphite, zofewa/zokhazikika, zida za silicon carbide, Zigawo za CVD silicon carbide,ndiZigawo zokutira za SiC/TaCndi m'masiku 30.

Ngati mukufuna zinthu za semiconductor pamwambapa,chonde musazengereze kulumikizana nafe nthawi yoyamba.

Tel: +86-13373889683

Watsapp: +86-15957878134

Email: sales01@semi-cera.com

Nthawi yotumiza: Aug-31-2024