1. Mawu Oyamba

Kuyika kwa ion ndi imodzi mwazinthu zazikulu zopanga madera ophatikizika. Zimatanthawuza njira yofulumizitsa mtengo wa ion ku mphamvu inayake (kawirikawiri mumtundu wa keV mpaka MeV) ndikuyiyika pamwamba pa chinthu cholimba kuti chisinthe mawonekedwe a pamwamba pa zinthuzo. Mu Integrated dera ndondomeko, zinthu olimba zambiri pakachitsulo, ndipo anaikamo zonyansa ayoni zambiri boron ayoni, ayoni phosphorous, ayoni arsenic, ayoni indium, ayoni germanium, etc. The ions anaikapo angasinthe madutsidwe pamwamba pa olimba ayoni. zinthu kapena kupanga PN mphambano. Pamene kukula kwa mabwalo ophatikizika kudachepetsedwa kukhala nthawi ya sub-micron, njira yoyika ion idagwiritsidwa ntchito kwambiri.

Mu njira yophatikizira yopangira dera, kuyika kwa ion nthawi zambiri kumagwiritsidwa ntchito pazigawo zakuya zokwiriridwa, zitsime zosinthika, kusintha kwamagetsi, gwero ndi kukhetsa kukulitsa, kuyika kwa gwero ndi kukhetsa, doping ya polysilicon pachipata, kupanga ma PN olumikizirana ndi resistors / capacitors, ndi zina zambiri. Pokonzekera silicon gawo lapansi zinthu pa insulators, kukwiriridwa okusayidi wosanjikiza amapangidwa ndi mkulu-concentration oxygen ion implantation, kapena wanzeru. kudula kumatheka ndi kuyika kwakukulu kwa hydrogen ion implantation.

Ion implantation imachitidwa ndi ion implantation, ndipo magawo ake ofunikira kwambiri ndi mlingo ndi mphamvu: mlingo umatsimikizira ndende yomaliza, ndipo mphamvu imatsimikizira mtunda (ie, kuya) kwa ayoni. Malinga ndi zofunikira pakupanga zida zosiyanasiyana, mikhalidwe yoyika imagawidwa kukhala yamphamvu kwambiri, yapakatikati, yapakatikati, yapakatikati, yapakatikati, kapena yamphamvu kwambiri. Kuti mupeze zotsatira zabwino zoyika, zoyikapo zosiyanasiyana ziyenera kukhala ndi zofunikira zosiyanasiyana.

Pambuyo pa kuikidwa kwa ayoni, nthawi zambiri kumakhala kofunikira kutsata njira yotentha kwambiri kuti mukonze kuwonongeka kwa latisi komwe kudachitika chifukwa choyika ma ion ndikuyambitsa ma ion odetsedwa. M'machitidwe achikhalidwe ophatikizika ozungulira, ngakhale kutentha kwa annealing kumakhudza kwambiri doping, kutentha kwa ion implantation process sikofunikira. Pamalo aukadaulo omwe ali pansi pa 14nm, njira zina zoyika ma ion ziyenera kuchitidwa m'malo otsika kapena otentha kwambiri kuti asinthe zotsatira za kuwonongeka kwa lattice, ndi zina zambiri.

2. ion implantation ndondomeko

2.1 Mfundo Zoyambira

Kuyika kwa ion ndi njira yopangira doping yomwe idapangidwa mzaka za m'ma 1960 yomwe ndi yapamwamba kuposa njira zachikhalidwe zakufalitsa m'mbali zambiri.

Kusiyana kwakukulu pakati pa ion implantation doping ndi miyambo yachikhalidwe yofalitsa doping ndi motere:

(1) Kugawidwa kwa ndende yonyansa m'dera la doped ndi kosiyana. Chidebe chachikulu cha ion implantation chimakhala mkati mwa kristalo, pomwe nsonga yoyipa kwambiri ya kufalikira kumakhala pamwamba pa kristalo. (2) Kuyika kwa ion ndi njira yomwe imachitika kutentha kapena kutentha pang'ono, ndipo nthawi yopanga ndi yochepa. Diffusion doping imafuna chithandizo chotalikirapo cha kutentha kwambiri. (3) Kuyika kwa ion kumalola kusankha kosinthika komanso kolondola kwa zinthu zoyikidwa. (4) Popeza zonyansa zimakhudzidwa ndi kufalikira kwa matenthedwe, mawonekedwe a mafunde opangidwa ndi ion implantation mu kristalo ndiabwino kuposa mawonekedwe opangidwa ndi kufalikira mu kristalo. (5) Kuyika kwa ion nthawi zambiri kumangogwiritsa ntchito photoresist ngati chigoba, koma kufalikira kwa doping kumafuna kukula kapena kuyika kwa filimu ya makulidwe akutiakuti ngati chigoba. (6) Kuyika kwa ion kwalowa m'malo mwa kufalikira ndikukhala njira yayikulu yopangira ma circulation masiku ano.

Pamene mtengo wa ayoni wokhala ndi mphamvu inayake iphulitsa chandamale cholimba (kawirikawiri chophwanyika), ma ma ion ndi ma atomu omwe ali pamalo omwe chandamale amalumikizana mosiyanasiyana, ndikusamutsira mphamvu ku maatomu omwe akuwafuna mwanjira inayake kuti asangalale kapena ayinize. iwo. Ma ion amathanso kutaya mphamvu zina mwa kutengerapo mwachangu, ndipo pamapeto pake amabalalitsidwa ndi maatomu omwe akufuna kapena kuyimitsa muzinthu zomwe mukufuna. Ngati ma jekeseniwo ali olemera, ma ion ambiri amabayidwa mu chandamale cholimba. M'malo mwake, ngati ma ion opangidwa ndi jekeseni ali opepuka, ma ion ambiri omwe amabayidwawo amadumphira pamalo omwe mukufuna. Kwenikweni, ma ion amphamvu kwambiri awa omwe amabadwira mu chandamale adzawombana ndi ma atomu a lattice ndi ma elekitironi mu chandamale cholimba mpaka mosiyanasiyana. Pakati pawo, kugundana pakati pa ma ion ndi maatomu olimba omwe amayang'ana kutha kuwonedwa ngati kugunda kolimba chifukwa ali pafupi kwambiri.

2.2 Main magawo a ion implantation

Kuyika kwa ion ndi njira yosinthika yomwe imayenera kukwaniritsa mapangidwe okhwima a chip ndi kupanga. Zofunikira zoyika ma ion ndi: mlingo, osiyanasiyana.

Mlingo (D) umatanthawuza kuchuluka kwa ayoni omwe amabayidwa pagawo lililonse la silicon wafer pamwamba, mu ma atomu pa lalikulu sentimita (kapena ma ion pa sikweya sentimita imodzi). D ikhoza kuwerengedwa motere:

Kumene D ndi mlingo wa implantation (chiwerengero cha ayoni/gawo); t ndi nthawi yoyika; Ine ndiye chitsulo chamakono; q ndiye mtengo wonyamulidwa ndi ion (chiwongola dzanja chimodzi ndi 1.6×1019C[1]); ndipo S ndi malo oyikapo.

Chimodzi mwazifukwa zazikulu zomwe implantation ya ion yakhala ukadaulo wofunikira pakupanga silicon wafer ndikuti imatha kuyika mobwerezabwereza mlingo womwewo wa zonyansa muzowotcha za silicon. Woyikapo amakwaniritsa cholinga ichi mothandizidwa ndi ndalama zabwino za ayoni. Pamene ma ion odetsedwa abwino amapanga mtengo wa ion, kuthamanga kwake kumatchedwa ion beam current, yomwe imayesedwa mu mA. Kuchuluka kwa mafunde apakati ndi otsika ndi 0.1 mpaka 10 mA, ndipo maulendo apamwamba ndi 10 mpaka 25 mA.

Kukula kwa ion mtengo wamakono ndikusintha kofunikira pakutanthauzira mlingo. Ngati pakalipano chikuwonjezeka, chiwerengero cha maatomu onyansa omwe amaikidwa pa nthawi ya unit nawonso amawonjezeka. Kukwera kwaposachedwa kumathandizira kukulitsa zokolola za silicon wafer (kubaya ma ayoni ochulukirapo panthawi yopanga mayunitsi), komanso kumayambitsa zovuta zofanana.

3. ion implantation zida

3.1 Mapangidwe Oyambira

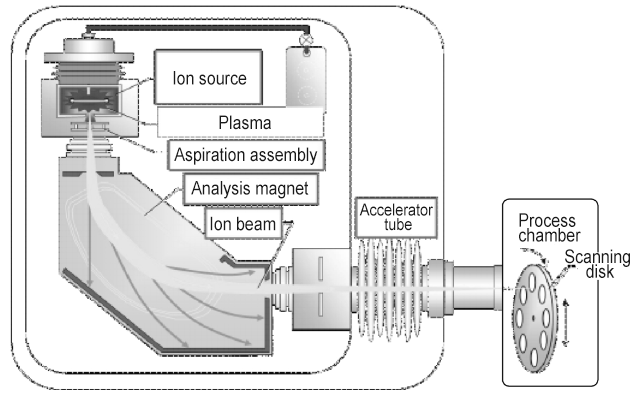

Zida zoyika ion zimaphatikizapo ma module 7 oyambira:

① gwero la ion ndi chotsitsa;

② misa analyzer (ie analytical maginito);

③ accelerator chubu;

④ sikani litayamba;

⑤ electrostatic neutralization dongosolo;

⑥ ndondomeko chipinda;

⑦ dongosolo lowongolera mlingo.

Ama module onse ali m'malo opanda vacuum okhazikitsidwa ndi vacuum system. Chojambula choyambirira cha ion implanter chikuwonetsedwa pachithunzichi.

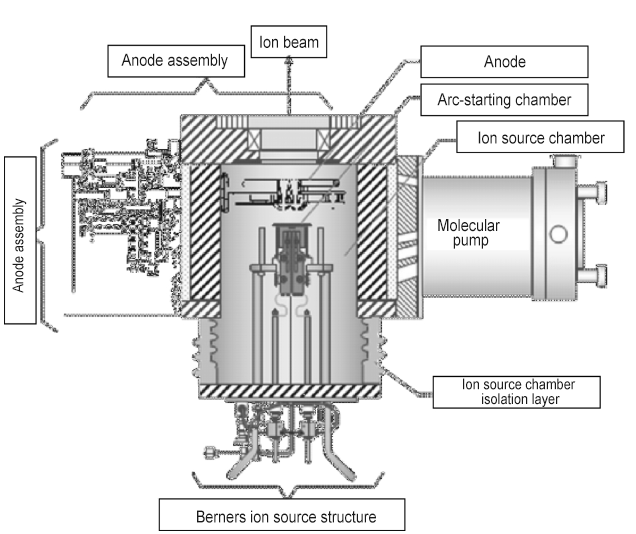

(1)ion source:

Nthawi zambiri m'chipinda cha vacuum chofanana ndi electrode yoyamwa. Zonyansa zomwe zikudikirira kubayidwa ziyenera kukhalapo mu ion state kuti ziwongoleredwe ndikufulumizitsidwa ndi gawo lamagetsi. Zomwe zimagwiritsidwa ntchito kwambiri B+, P+, As+, ndi zina zambiri zimapezeka ndi maatomu a ionizing kapena mamolekyu.

Magwero odetsedwa omwe amagwiritsidwa ntchito ndi BF3, PH3 ndi AsH3, ndi zina zambiri, ndipo mawonekedwe awo akuwonetsedwa pachithunzi pansipa. Ma elekitironi otulutsidwa ndi ulusiwo amawombana ndi maatomu a mpweya kuti apange ayoni. Ma electron nthawi zambiri amapangidwa ndi gwero lotentha la tungsten filament. Mwachitsanzo, gwero la Berners ion, cathode filament imayikidwa mu chipinda cha arc ndi mpweya wolowera. Khoma lamkati la chipinda cha arc ndi anode.

Pamene gwero la gasi likuyambitsidwa, mphamvu yaikulu yamakono imadutsa mu filament, ndipo voteji ya 100 V imagwiritsidwa ntchito pakati pa ma electrode abwino ndi oipa, omwe amapanga ma electron amphamvu kwambiri kuzungulira filament. Ma ion abwino amapangidwa pambuyo poti ma elekitironi amphamvu kwambiri agundana ndi mamolekyu a gasi.

Maginito akunja amagwiritsa ntchito maginito ofanana ndi filament kuti awonjezere ionization ndi kukhazikika kwa plasma. M'chipinda cha arc, kumapeto kwina kokhudzana ndi ulusi, pali chowonetsera molakwika chomwe chimawonetsa ma electron kuti apititse patsogolo kukula ndi mphamvu ya ma electron.

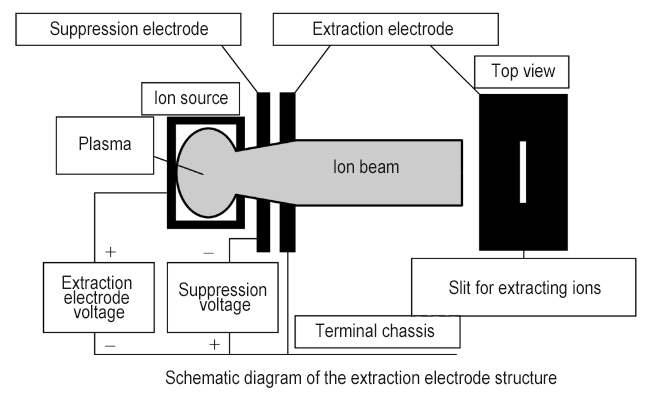

(2)Kuyamwa:

Amagwiritsidwa ntchito kusonkhanitsa ma ion abwino opangidwa mu chipinda cha arc cha gwero la ion ndikuwapanga kukhala mtengo wa ion. Popeza chipinda cha arc ndi anode ndipo cathode imapanikizika molakwika pa electrode yoyamwa, gawo lamagetsi lomwe limapangidwa limawongolera ma ion abwino, kuwapangitsa kuti asunthire ku electrode yoyamwa ndikutulutsidwa kuchokera pagawo la ion, monga momwe tawonetsera pachithunzichi. . Kuchuluka kwa mphamvu yamagetsi kumapangitsanso mphamvu ya kinetic yomwe ma ions amapeza pambuyo pothamanga. Palinso kupondereza voteji pa suction electrode kuteteza kusokoneza ma elekitironi mu plasma. Panthawi imodzimodziyo, electrode yopondereza imatha kupanga ma ion mumtengo wa ion ndikuwayika mumtsinje wofanana wa ion mtengo kuti udutse mu implanter.

(3)Mass analyzer:

Pakhoza kukhala mitundu yambiri ya ma ion opangidwa kuchokera ku gwero la ion. Pansi pa mathamangitsidwe a anode voteji, ma ions amayenda pa liwiro lalikulu. Ma ma ion osiyanasiyana ali ndi mayunitsi osiyanasiyana a misa ya atomiki ndi ma retiwoni osiyanasiyana a misa-to-charge.

(4)Accelerator chubu:

Kuti mupeze liwiro lalikulu, mphamvu zambiri zimafunikira. Kuphatikiza pa gawo lamagetsi loperekedwa ndi anode ndi misa analyzer, gawo lamagetsi loperekedwa mu chubu cha accelerator likufunikanso kuti lipititse patsogolo. The accelerator chubu imakhala ndi ma elekitirodi angapo olekanitsidwa ndi dielectric, ndipo voteji yoyipa pa maelekitirodi imawonjezeka motsatizana kudzera mu kulumikizana kwa mndandanda. Kukwera kwa voliyumu yonse, ndikokulirapo kwa liwiro lomwe ma ion amapeza, ndiko kuti, mphamvu yonyamula. Mphamvu zambiri zimatha kulola ma ion odetsedwa kubayidwa mozama mu chowotcha cha silicon kuti apange mphambano yakuya, pomwe mphamvu yotsika ingagwiritsidwe ntchito kupanga mphambano yosaya.

(5)Kusanthula disk

Mtengo wa ion wokhazikika nthawi zambiri umakhala wawung'ono kwambiri m'mimba mwake. Kutalika kwa mtengo woyikapo pamtengo wapakati ndi pafupifupi 1 cm, ndipo choyikapo chachikulu chamtengowo chimakhala pafupifupi 3 cm. Chophimba chonse cha silicon chiyenera kuphimbidwa ndi kusanthula. The repeatability wa mlingo implantation anatsimikiza ndi kupanga sikani. Nthawi zambiri, pali mitundu inayi ya makina ojambulira implanter:

① electrostatic sikani;

② makina kupanga sikani;

③ kusanthula kosakanizidwa;

④ kusanja kofanana.

(6)Static magetsi neutralization dongosolo:

Panthawi yoyikapo, mtengo wa ion umagunda chowotcha cha silicon ndikupangitsa kuti mtengo uunjike pamwamba pa chigoba. Kuchuluka kwa mtengowo kumasintha kuchuluka kwa mtengo wa ion mtengo, kupangitsa kuti mtengowo ukhale wokulirapo komanso kugawa kwa mlingo. Ikhoza ngakhale kudutsa pamwamba pa oxide wosanjikiza ndi kuchititsa chipangizo kulephera. Tsopano, chowotcha cha silicon ndi mtengo wa ion nthawi zambiri zimayikidwa pamalo okhazikika a plasma olimba kwambiri otchedwa plasma electron shower system, yomwe imatha kuwongolera kulipiritsa kwa silicon wafer. Njirayi imatulutsa ma elekitironi kuchokera ku plasma (kawirikawiri argon kapena xenon) mu chipinda cha arc chomwe chili mu njira ya ion mtengo wa ion ndi pafupi ndi silicon wafer. Madzi a m'magazi amasefedwa ndipo ma elekitironi achiwiri okha ndi omwe amatha kufika pamwamba pa silicon wafer kuti achepetse mtengo wabwino.

(7)Process cavity:

Kuyika kwa matabwa a ion muzitsulo za silicon kumachitika mu chipinda chopangira. Chipinda chogwirira ntchito ndi gawo lofunikira la choyikapo, kuphatikiza makina ojambulira, malo otsekera okhala ndi loko yotsekera ndikutsitsa zowotcha za silicon, makina osinthira a silicon wafer, ndi makina owongolera makompyuta. Kuphatikiza apo, pali zida zina zowonera Mlingo ndikuwongolera zomwe zimachitika panjira. Ngati makina ojambulira agwiritsidwa ntchito, malo okwerera amakhala okulirapo. The vacuum chipinda ndondomeko amapopedwera pansi kupanikizika chofunika ndi ndondomeko ndi Mipikisano siteji makina mpope, turbomolecular pampu, ndi condensation mpope, amene nthawi zambiri pafupifupi 1 × 10-6Torr kapena zochepa.

(8)Dosing control system:

Kuwunika kwanthawi yeniyeni mu choyikapo cha ion kumachitika poyezera mtengo wa ion womwe umafika pachiwopsezo cha silicon. Mtengo wa ion wamakono umayesedwa pogwiritsa ntchito sensa yotchedwa Faraday cup. Mu dongosolo losavuta la Faraday, pali sensa yamakono mu njira ya ion mtengo yomwe imayesa zamakono. Komabe, izi zimabweretsa vuto, popeza mtengo wa ion umakhudzidwa ndi sensa ndikupanga ma elekitironi achiwiri omwe angayambitse kuwerengedwa kolakwika kwapano. Dongosolo la Faraday limatha kupondereza ma elekitironi achiwiri pogwiritsa ntchito magetsi kapena maginito kuti apeze zowerengera zenizeni. Zomwe zimayezedwa ndi dongosolo la Faraday zimadyetsedwa mu chowongolera chamagetsi chamagetsi, chomwe chimakhala ngati chowonjezera chamakono (chomwe chimadziunjikira mosalekeza mtengo wamtengo wapatali). Wowongolera amagwiritsidwa ntchito kugwirizanitsa chiwerengero chamakono ndi nthawi yofananira yoyikidwa ndikuwerengera nthawi yofunikira pa mlingo wina.

3.2 Kukonza zowonongeka

Kuyika kwa ion kudzagwetsa maatomu kuchokera pamiyala ndikuwononga nthiti ya silicon. Ngati mlingo wobzalidwa uli waukulu, wosanjikiza wobzalidwa udzakhala wa amorphous. Kuphatikiza apo, ma ion oyikidwa kwenikweni sakhala m'malo a silicon, koma amakhala m'malo opumira. Zodetsedwa zapakati izi zitha kutsegulidwa pakangotentha kwambiri.

Annealing imatha kutentha chowotcha cha silicon choyikidwa kuti chikonze zolakwika za lattice; imathanso kusuntha maatomu osadetsedwa kupita kumalo otsetsereka ndikuwayambitsa. Kutentha kofunikira kuti mukonze zolakwika za lattice ndi pafupifupi 500 ° C, ndipo kutentha kofunikira kuti maatomu osadetsedwa ayambe kugwira ntchito ndi pafupifupi 950 ° C. Kutsegula kwa zonyansa kumakhudzana ndi nthawi ndi kutentha: nthawi yayitali komanso kutentha kwapamwamba, zonyansa zimayendetsedwa. Pali njira ziwiri zoyambira zowotchera ma silicon:

① ng'anjo yotentha kwambiri;

② kuthamanga kwachangu (RTA).

Kutentha kwa ng'anjo yotentha kwambiri: Kutentha kwa ng'anjo yotentha kwambiri ndi njira yachikhalidwe yopangira ng'anjo, yomwe imagwiritsa ntchito ng'anjo yotentha kwambiri kuti itenthetse chophika cha silicon mpaka 800-1000 ℃ ndikuchisunga kwa mphindi 30. Pakutentha uku, maatomu a silikoni amabwerera ku malo otchinga, ndipo maatomu osadetsedwa amathanso kulowa m’malo mwa maatomu a silikoni ndi kulowa m’chingwe. Komabe, kutentha kwa kutentha ndi nthawi yotereyi kudzatsogolera kufalikira kwa zonyansa, zomwe ndi zomwe makampani opanga IC amakono sakufuna kuwona.

Rapid Thermal Annealing: Rapid thermal annealing (RTA) imagwira zophika za silicon ndi kutentha kwachangu kwambiri komanso kwaufupi pa kutentha komwe mukufuna (nthawi zambiri 1000 ° C). Kuphatikizika kwa zowotcha za silicon zoyikidwa nthawi zambiri kumachitika mu purosesa yotentha yothamanga ndi Ar kapena N2. Kutentha kofulumira kwa kutentha ndi nthawi yochepa kungathe kukonzanso zowonongeka za lattice, kuyambitsa zonyansa ndi kulepheretsa kufalikira kwa zonyansa. RTA imathanso kuchepetsa kufalikira kwapang'onopang'ono ndipo ndiyo njira yabwino kwambiri yowongolera kuya kwa mphambano m'ma implants ozama.

—————————————————————————————————————————————————— ————————————-

Semicera ikhoza kuperekazigawo za graphite, zofewa/zokhazikika, zida za silicon carbide, Zigawo za CVD silicon carbide,ndiZigawo zokutira za SiC/TaCndi m'masiku 30.

Ngati mukufuna zinthu za semiconductor pamwambapa,chonde musazengereze kulumikizana nafe nthawi yoyamba.

Tel: +86-13373889683

Watsapp: +86-15957878134

Email: sales01@semi-cera.com

Nthawi yotumiza: Aug-31-2024