Mawu Oyamba Amodzi

Etching mu Integrated circuit kupanga ndondomeko amagawidwa mu:

- kuchepa kwa madzi;

-Kupukuta kowuma.

M'masiku oyambirira, etching yonyowa inkagwiritsidwa ntchito kwambiri, koma chifukwa cha malire ake pakuwongolera m'lifupi mwake ndikuwongolera njira, njira zambiri pambuyo pa 3μm zimagwiritsa ntchito etching youma. Kunyowa kumangogwiritsidwa ntchito kuchotsa zigawo zina zapadera zakuthupi ndikuyeretsa zotsalira.

Dry etching imatanthawuza njira yogwiritsira ntchito ma etchants a gaseous chemical etchants kuti agwirizane ndi zinthu zomwe zili pawafa kuti achotse mbali ya zinthu zomwe zimayenera kuchotsedwa ndikupanga zinthu zomwe zimawonongeka, zomwe zimachotsedwa mu chipinda chochitiramo. Etchant nthawi zambiri imapangidwa mwachindunji kapena mosadukiza kuchokera ku plasma ya mpweya wotsekemera, kotero kuti kuuma kowuma kumatchedwanso plasma etching.

1.1 Plasma

Plasma ndi mpweya womwe uli mumkhalidwe wofooka wa ionized wopangidwa ndi kutulutsa kwamphamvu kwa gasi wowotchera pansi pa mphamvu yamagetsi akunja amagetsi (monga opangidwa ndi ma frequency a radio). Zimaphatikizapo ma electron, ayoni ndi tinthu tating'onoting'ono tating'onoting'ono. Pakati pawo, tinthu ting'onoting'ono tating'onoting'ono tating'ono tating'onoting'ono titha kuchitapo kanthu mwachindunji ndi zinthu zomwe zidakhazikika kuti zikwaniritse etching, koma mankhwala oyeretsedwawa nthawi zambiri amangopezeka muzinthu zochepa kwambiri ndipo sizolunjika; pamene ayoni ali ndi mphamvu zinazake, amatha kuzikika ndi kudumpha mwachindunji, koma kutsika kwamphamvu kwa thupi koyera kumakhala kotsika kwambiri ndipo kusankha kumakhala koyipa kwambiri.

Etching yambiri ya plasma imatsirizidwa ndi kutenga nawo gawo kwa tinthu tating'ono ndi ayoni nthawi imodzi. Pochita izi, bombardment ya ion ili ndi ntchito ziwiri. Mmodzi ndi kuwononga zomangira atomiki pamwamba pa zozikika zakuthupi, potero kuonjezera mlingo umene ndale particles amachita nawo; china ndi kugwetsa zimene mankhwala waikamo pa mmene mawonekedwe kuti atsogolere etchant kwathunthu kukhudzana pamwamba pa zinthu zokhazikika, kotero kuti etching akupitiriza.

Zomwe zimayikidwa m'mbali mwazomwe zimakhazikika sizingachotsedwe bwino ndi bombardment ya ion, potero kutsekereza kutsekeka kwa makoma am'mbali ndikupanga etching ya anisotropic.

Njira yachiwiri etching

2.1 Kunyowa ndi Kutsuka

Wet etching ndi imodzi mwamaukadaulo akale kwambiri omwe amagwiritsidwa ntchito popanga madera ophatikizika. Ngakhale njira zambiri zonyowa zasinthidwa ndi anisotropic dry etching chifukwa cha etching yake ya isotropic, imakhalabe ndi gawo lofunikira pakuyeretsa zigawo zosafunikira zazikulu zazikulu. Makamaka mu etching wa zotsalira kuchotsa okusayidi ndi epidermal stripping, ndi zothandiza kwambiri ndi ndalama kuposa youma etching.

Zinthu za etching yonyowa makamaka zikuphatikizapo silicon oxide, silicon nitride, single crystal silicon ndi polycrystalline silicon. Kunyowa kwa silicon oxide nthawi zambiri kumagwiritsa ntchito hydrofluoric acid (HF) ngati chonyamulira chachikulu. Pofuna kupititsa patsogolo kusankha, kusungunula hydrofluoric acid yotsekedwa ndi ammonium fluoride imagwiritsidwa ntchito pochita izi. Pofuna kusunga kukhazikika kwa pH mtengo, pang'ono asidi amphamvu kapena zinthu zina zikhoza kuwonjezeredwa. Doped silicon oxide ndiyosavuta kuwononga kuposa silicon oxide yoyera. Kuvula mankhwala onyowa kumagwiritsidwa ntchito makamaka kuchotsa photoresist ndi chigoba cholimba (silicon nitride). Hot phosphoric acid (H3PO4) ndiye chinthu chachikulu chamadzimadzi chomwe chimagwiritsidwa ntchito povula mankhwala onyowa kuti achotse silicon nitride, ndipo ali ndi kusankha bwino kwa silicon oxide.

Kuyeretsa konyowa kumakhala kofanana ndi kukokera konyowa, ndipo makamaka kumachotsa zowononga pamwamba pa zowotcha za silicon kudzera muzochita zamankhwala, kuphatikiza tinthu tating'onoting'ono, organic matter, zitsulo ndi oxides. Kuyeretsa konyowa kwakukulu ndi njira yonyowa yamadzimadzi. Ngakhale kuyeretsa kowuma kumatha kusintha njira zambiri zoyeretsera zonyowa, palibe njira yomwe ingalowe m'malo mwa kuyeretsa konyowa.

Mankhwala omwe amagwiritsidwa ntchito kawirikawiri poyeretsa madzi ndi monga sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, hydrogen peroxide, ammonium hydroxide, ammonium fluoride, ndi zina zotero. kupanga njira yoyeretsera, monga SC1, SC2, DHF, BHF, ndi zina.

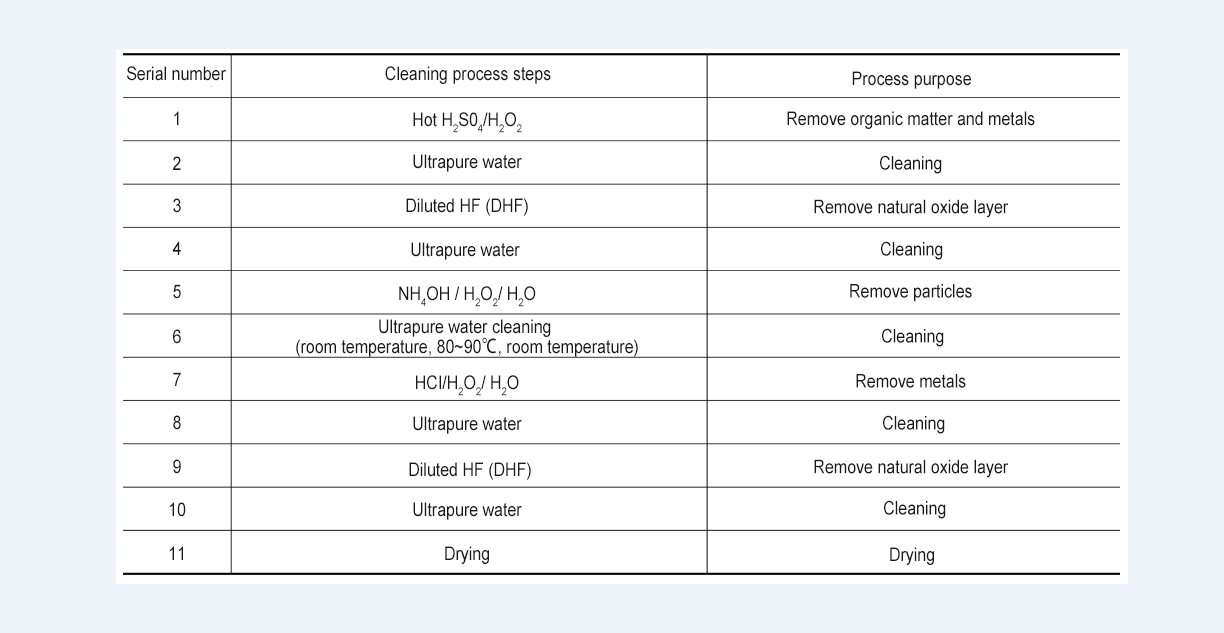

Kuyeretsa nthawi zambiri ntchito ndondomeko pamaso oxide filimu mafunsidwe, chifukwa yokonza okusayidi filimu ayenera kuchitidwa pa mwamtheradi woyera pakachitsulo mtanda wafer pamwamba. Njira yodziwika bwino yoyeretsera silicon wafer ndi motere:

2.2 Dry Etching ndi Kuyeretsa

2.2.1 Dry Etching

Kuuma kowuma m'makampani kumatanthawuza etching ya plasma, yomwe imagwiritsa ntchito madzi a m'magazi omwe ali ndi ntchito yowonjezera kuti atchule zinthu zinazake. Dongosolo la zida munjira zazikulu zopangira zimagwiritsa ntchito plasma yotsika yotsika yosagwirizana.

Etching ya plasma imagwiritsa ntchito mitundu iwiri yotulutsa: capacitive kuphatikiza kutulutsa komanso kutulutsa kophatikizana.

Mu capacitively coupled discharge mode: plasma imapangidwa ndikusungidwa m'magawo awiri ofananira ndi ma radio frequency (RF) magetsi. Kuthamanga kwa mpweya nthawi zambiri kumakhala millitorr angapo mpaka makumi a millitorr, ndipo mlingo wa ionization ndi wochepera 10-5. M'njira yophatikizika yotulutsa: nthawi zambiri pamagetsi otsika a gasi (makumi a millitorr), plasma imapangidwa ndikusungidwa ndi mphamvu yolumikizira yolumikizana. Mlingo wa ionization nthawi zambiri umakhala wokulirapo kuposa 10-5, motero umatchedwanso kuti plasma yapamwamba kwambiri. Magwero a plasma apamwamba kwambiri amathanso kupezeka kudzera pa electron cyclotron resonance ndi cyclotron wave discharge. Ma plasma amphamvu kwambiri amatha kukhathamiritsa kuchuluka kwa etching ndi kusankha kwa etching pomwe akuchepetsa kuwonongeka kwa etching poyang'anira pawokha kuthamanga kwa ion ndi mphamvu ya bombardment ya ion kudzera pamagetsi akunja a RF kapena ma microwave ndi magetsi a RF bias pa gawo lapansi.

The youma etching ndondomeko ndi motere: etching mpweya jekeseni mu zingalowe anachita chipinda, ndipo pambuyo kuthamanga mu chipinda anachita okhazikika, plasma kwaiye ndi wailesi pafupipafupi kuwala kumaliseche; atakhudzidwa ndi ma electron othamanga kwambiri, amawola kuti apange ma radicals aulere, omwe amafalikira pamwamba pa gawo lapansi ndipo amadsorbed. Pansi pa bombardment ya ayoni, ma adsorbed free radicals amakumana ndi ma atomu kapena mamolekyu pamwamba pa gawo lapansi kuti apange zinthu zotulutsa mpweya, zomwe zimatulutsidwa m'chipinda chochitiramo. Njirayi ikuwonetsedwa mu chithunzi chotsatirachi:

Dry etching process zitha kugawidwa m'magulu anayi awa:

(1)Physi sputtering etching: Zimadalira makamaka ma ion amphamvu mu plasma kuti awombe pamwamba pa zinthu zokhazikika. Kuchuluka kwa ma atomu omwe atayika kumadalira mphamvu ndi ngodya ya tinthu tating'onoting'ono. Pamene mphamvu ndi ngodya zimakhalabe zosasinthika, kuchuluka kwa sputtering kwa zipangizo zosiyanasiyana nthawi zambiri kumasiyana ndi 2 mpaka 3 nthawi, kotero palibe kusankha. The anachita ndondomeko makamaka anisotropic.

(2)Chemical etching: Plasma imapereka maatomu agasi-gawo ndi mamolekyu, omwe amalumikizana ndi zinthu pamwamba pa zinthuzo kuti apange mpweya wosakhazikika. Izi mwachilengedwe zimachita kusankha bwino ndipo zimawonetsa mawonekedwe a isotropic osaganizira kapangidwe ka latisi.

Mwachitsanzo: Si (yolimba) + 4F → SiF4 (gaseous), photoresist + O (gaseous) → CO2 (gaseous) + H2O (gaseous)

(3)Etching yoyendetsedwa ndi ion: Ma ion ndi tinthu tating'onoting'ono tomwe timayambitsa tinthu tating'onoting'ono tokhala ndi mphamvu. Kuchita bwino kwa tinthu tating'onoting'ono totengera mphamvu ngati kameneka ndi kopitilira muyeso umodzi wa ukulu kuposa wamba wamba kapena mankhwala. Pakati pawo, kukhathamiritsa kwa thupi ndi mankhwala magawo a ndondomekoyi ndi pachimake kulamulira etching ndondomeko.

(4)Ion-barrier composite etching: Imatanthawuza makamaka kubadwa kwa chotchinga chotchinga cha polima ndi tinthu tating'onoting'ono panthawi ya etching. Plasma imafuna chitetezo chotere kuti chiteteze kukhudzidwa kwa makoma am'mbali panthawi yolowera. Mwachitsanzo, kuwonjezera C ku Cl ndi Cl2 etching kumatha kutulutsa chlorocarbon pawiri wosanjikiza panthawi yokhota kuti ateteze makoma am'mbali kuti asamangidwe.

2.2.1 Kuyeretsa kowuma

Kuyeretsa kowuma kumatanthauza kuyeretsa plasma. Ma ion mu plasma amagwiritsidwa ntchito kuphulitsa pamwamba kuti atsukidwe, ndipo ma atomu ndi mamolekyu omwe ali mumkhalidwe woyendetsedwa amalumikizana ndi pamwamba kuti atsukidwe, kuti achotse ndi phulusa la photoresist. Mosiyana ndi etching youma, magawo a kuyeretsa kowuma nthawi zambiri samaphatikizira kusankha kowongolera, chifukwa chake mapangidwe ake ndi osavuta. Pakupanga kwakukulu, mpweya wochokera ku fluorine, mpweya kapena haidrojeni amagwiritsidwa ntchito makamaka ngati gawo lalikulu la plasma. Kuphatikiza apo, kuwonjezera kuchuluka kwa plasma ya argon kumatha kukulitsa mphamvu ya bombardment ya ion, potero kumapangitsa kuyeretsa bwino.

Poyeretsa plasma youma, njira yakutali ya plasma imagwiritsidwa ntchito. Izi zili choncho chifukwa poyeretsa, akuyembekeza kuchepetsa kuphulika kwa ma ion mu plasma kuti athetse kuwonongeka komwe kumachitika chifukwa cha bombardment; ndi kumatheka kachitidwe mankhwala free ankafuna kusintha zinthu mopitirira akhoza kusintha kuyeretsa dzuwa. Madzi a m'magazi akutali angagwiritse ntchito ma microwave kuti apange plasma yokhazikika komanso yochuluka kwambiri kunja kwa chipinda chochitira, ndikupanga ma radicals ambiri aulere omwe amalowa m'chipinda chochitiramo kuti akwaniritse zomwe zimafunikira pakuyeretsa. Ambiri mwa gasi woyeretsa wowuma pamsika amagwiritsa ntchito mpweya wa fluorine, monga NF3, ndipo oposa 99% a NF3 amawola mu microwave plasma. Pafupifupi palibe bombardment ya ayoni pakuyeretsa kowuma, chifukwa chake ndizothandiza kuteteza chophatikizira cha silicon kuti chisawonongeke ndikukulitsa moyo wachipindacho.

Zida zitatu zonyowa zomangira ndi zoyeretsera

3.1 Makina oyeretsa amtundu wa tanki

Makina otsuka amtundu wa mbiya amapangidwa makamaka ndi gawo lotsegulira lakutsogolo, gawo lopatsira / kutsitsa, gawo lotulutsa mpweya, gawo la tanki yamadzimadzi, gawo la tanki yamadzi ya deionized, thanki yowumitsa. module ndi control module. Ikhoza kuyeretsa mabokosi angapo a zowomba panthawi imodzi ndipo imatha kukwaniritsa zowuma ndi zowuma.

3.2 Trench Wafer Etcher

3.3 Chida Chimodzi Chokha Chonyowa Chonyowa

Malinga ndi zolinga zosiyanasiyana ndondomeko, imodzi yopyapyala chonyowa ndondomeko zipangizo akhoza kugawidwa m'magulu atatu. Gulu loyamba ndi zida zotsuka zotsuka zokhazokha, zomwe zolinga zake zoyeretsera zimaphatikizapo tinthu tating'onoting'ono, zinthu za organic, wosanjikiza wa oxide wachilengedwe, zonyansa zachitsulo ndi zoipitsa zina; gulu lachiwiri ndi imodzi yopyapyala scrubbing zida, amene cholinga chake chachikulu ndi kuchotsa particles pamwamba pa mpanda; gulu lachitatu ndi single wafer etching zida, amene makamaka ntchito kuchotsa mafilimu woonda. Malingana ndi zolinga zosiyanasiyana za ndondomeko, zida zopangira nsalu imodzi zikhoza kugawidwa m'magulu awiri. Mtundu woyamba ndi wofatsa etching zida, amene makamaka ntchito kuchotsa pamwamba filimu kuwonongeka zigawo chifukwa cha mkulu-mphamvu ion implantation; mtundu wachiwiri ndi nsembe wosanjikiza kuchotsa zida, amene makamaka ntchito kuchotsa chotchinga zigawo pambuyo yopyapyala kupatulira kapena mankhwala makina kupukuta.

Kuchokera pamalingaliro a zomangamanga zonse zamakina, kapangidwe kake ka mitundu yonse ya zida zonyowa zamtundu umodzi ndizofanana, zomwe zimakhala ndi magawo asanu ndi limodzi: chimango chachikulu, makina ophatikizira ophatikizika, gawo lachipinda, gawo lachipinda, gawo lamadzimadzi ndi kusamutsa gawo, pulogalamu yamapulogalamu. ndi module control electronic.

3.4 Chida Chimodzi Choyeretsera Wafer

Chida chimodzi chotsuka chotsuka chimapangidwa potengera njira yachikhalidwe ya RCA yoyeretsera, ndipo cholinga chake ndikuyeretsa tinthu tating'onoting'ono, organic, wosanjikiza wa oxide wachilengedwe, zonyansa zachitsulo ndi zoipitsa zina. Pankhani yogwiritsira ntchito ndondomeko, zipangizo zoyeretsera zowomba zamtundu umodzi zimagwiritsidwa ntchito kwambiri kutsogolo ndi kumbuyo kwa njira zopangira makina osakanikirana, kuphatikizapo kuyeretsa isanayambe kapena itatha kupanga filimu, kuyeretsa pambuyo pa plasma etching, kuyeretsa pambuyo pa kuika ion, kuyeretsa pambuyo pa mankhwala. makina kupukuta, ndi kuyeretsa pambuyo mafunsidwe zitsulo. Kupatula njira yotentha kwambiri ya phosphoric acid, zida zotsuka zotsuka imodzi zimayenderana ndi njira zonse zoyeretsera.

3.5 Chida Chowotcha Chimodzi Chokha

Cholinga cha makina opangira ma wafer omwe amawotchera kwambiri amakhala owonda kwambiri. Malinga ndi cholinga ndondomeko, zikhoza kugawidwa m'magulu awiri, kutanthauza, kuwala etching zipangizo (ntchito kuchotsa pamwamba filimu kuwonongeka wosanjikiza chifukwa cha mkulu-mphamvu ion implantation) ndi nsembe wosanjikiza kuchotsa zipangizo (ntchito kuchotsa chotchinga wosanjikiza pambuyo yopyapyala. kupatulira kapena kupukuta ndi makina opangira mankhwala). Zida zomwe zimayenera kuchotsedwa panthawiyi zimaphatikizapo silicon, silicon oxide, silicon nitride ndi zigawo zafilimu zachitsulo.

Zida zinayi zowuma zowuma ndi zoyeretsera

4.1 Gulu la zida za plasma etching

Kuphatikiza pa zida za ion sputtering etching zomwe zili pafupi ndi momwe thupi limagwirira ntchito komanso zida za degumming zomwe zili pafupi ndi momwe zimakhalira ndi mankhwala, etching ya plasma imatha kugawidwa m'magulu awiri molingana ndi ukadaulo wowongolera wa plasma:

-Capacitively Coupled Plasma (CCP) etching;

-Inductively Coupled Plasma (ICP) etching.

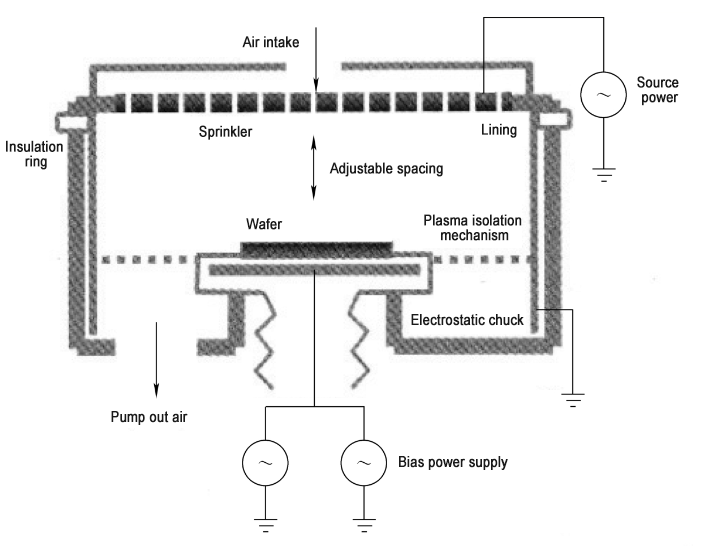

4.1.1 CCP

Capacitively kuphatikiza plasma etching ndi kulumikiza wailesi pafupipafupi magetsi kwa mmodzi kapena onse a maelekitirodi kumtunda ndi m'munsi mu chipinda reaction, ndi madzi a m'magazi pakati pa mbale ziwiri kupanga capacitor mu chophweka ofanana dera.

Pali njira ziwiri zoyambirira zaukadaulo ngati izi:

Imodzi ndi etching yoyambirira ya plasma, yomwe imalumikiza magetsi a RF ku maelekitirodi apamwamba komanso ma elekitirodi otsika pomwe chowotchacho chimakhala chokhazikika. Chifukwa madzi a m'magazi opangidwa motere sangapange chiwombankhanga chokwanira cha ayoni pamwamba pa chophikacho, mphamvu ya bombardment ya ion imakhala yochepa, ndipo nthawi zambiri imagwiritsidwa ntchito ngati silicon etching yomwe imagwiritsa ntchito tinthu tating'onoting'ono ngati gawo lalikulu.

Winawo ndi reactive ion etching (RIE), yomwe imalumikiza magetsi a RF ndi electrode yapansi pomwe pali chophatikizika, ndikuyika ma elekitirodi apamwamba ndi malo okulirapo. Tekinoloje iyi imatha kupanga sheath yokulirapo ya ion, yomwe ili yoyenera kupangira ma dielectric etching omwe amafunikira mphamvu ya ion yapamwamba kuti achite nawo zomwe zikuchitika. Pamaziko a ma ion etching oyambilira, gawo lamagetsi la DC lomwe limayenderana ndi gawo lamagetsi la RF limawonjezedwa kuti lipange ExB drift, yomwe imatha kukulitsa mwayi wogunda ma elekitironi ndi tinthu tating'onoting'ono, potero kuwongolera kuchuluka kwa plasma ndi kuchuluka kwa etching. Etching iyi imatchedwa magnetic field enhanced reactive ion etching (MERIE).

Matekinoloje atatu omwe ali pamwambawa ali ndi vuto lofanana, ndiko kuti, ndende ya plasma ndi mphamvu zake sizingathe kuyendetsedwa mosiyana. Mwachitsanzo, kuti muwonjezere kuchuluka kwa etching, njira yowonjezerera mphamvu ya RF ingagwiritsidwe ntchito kuonjezera kuchuluka kwa plasma, koma mphamvu yowonjezereka ya RF idzapangitsa kuti mphamvu ya ion ichuluke, zomwe zingayambitse kuwonongeka kwa zida zomwe zili pamagetsi. mkate wophika mkate. M'zaka khumi zapitazi, ukadaulo wa capacitive coupling watengera kapangidwe ka magwero angapo a RF, omwe amalumikizidwa ndi maelekitirodi apamwamba ndi apansi motsatana kapena onse ndi ma elekitirodi apansi.

Posankha ndikufananiza ma frequency osiyanasiyana a RF, malo a electrode, malo, zida ndi magawo ena ofunikira amalumikizidwa wina ndi mnzake, kuchuluka kwa plasma ndi mphamvu ya ion kumatha kugawidwa momwe mungathere.

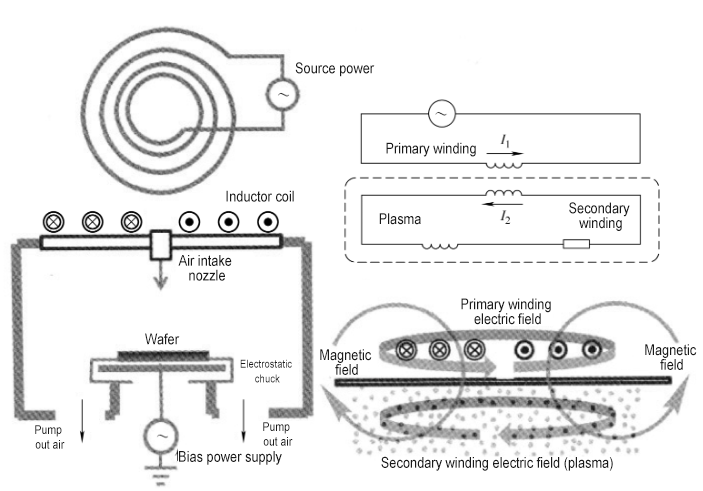

4.1.2 ICP

Etching ya plasma yolumikizidwa mokhazikika ndikuyika seti imodzi kapena zingapo zolumikizidwa kumagetsi amagetsi pawayilesi kapena kuzungulira chipindacho. Ma alternating maginito opangidwa ndi ma frequency a radio mu koyilo amalowa m'chipinda chochitiramo kudzera pawindo la dielectric kuti apititse patsogolo ma electron, potero amatulutsa plasma. Mu gawo losavuta lofananalo (transformer), koyilo ndiye njira yoyamba yomangira, ndipo madzi a m'magazi ndi njira yachiwiri yomangira.

Njira yolumikizira iyi imatha kukwaniritsa kuchuluka kwa plasma komwe kumakhala kopitilira muyeso umodzi wa ukulu kuposa kuphatikizika kwa capacitive pamphamvu yotsika. Kuphatikiza apo, mphamvu yachiwiri ya RF imalumikizidwa ndi malo opindika ngati njira yopangira magetsi kuti apereke mphamvu ya bombardment ya ion. Chifukwa chake, kuchuluka kwa ma ion kumadalira komwe kumachokera mphamvu ya koyilo ndipo mphamvu ya ion imadalira mphamvu yamagetsi, potero imakwaniritsa kufalikira kwamphamvu komanso mphamvu.

4.2 Zipangizo za Plasma Etching

Pafupifupi ma etchants onse mu etching youma amapangidwa mwachindunji kapena mwanjira ina kuchokera ku plasma, motero kuyanika kowuma kumatchedwa plasma etching. Plasma etching ndi mtundu wa plasma etching m'lingaliro lalikulu. M'mapangidwe awiri oyambirira a mbale yathyathyathya, imodzi ndiyo kuyika mbale pomwe pali chowotcha ndipo mbale ina imalumikizidwa ndi gwero la RF; chinacho n’chosiyana. M'mapangidwe akale, malo a mbale yokhazikika nthawi zambiri amakhala okulirapo kuposa gawo la mbale yolumikizidwa ndi gwero la RF, ndipo kupanikizika kwa gasi mu riyakitala kumakhala kwakukulu. Chophimba cha ion chomwe chimapangidwa pamwamba pa chophikacho chimakhala chochepa kwambiri, ndipo chophikacho chikuwoneka ngati "chomizidwa" mu plasma. Etching makamaka anamaliza ndi anachita mankhwala pakati yogwira particles mu plasma ndi pamwamba pa zinthu zokhazikika. Mphamvu ya bombardment ya ion ndi yaying'ono kwambiri, ndipo kutenga nawo gawo mu etching ndikotsika kwambiri. Mapangidwe awa amatchedwa plasma etching mode. Mu mapangidwe ena, chifukwa kuchuluka kwa kutenga nawo gawo pakuphulika kwa ayoni ndikokulirapo, kumatchedwa reactive ion etching mode.

4.3 Zida Zopangira Ma Ion Etching

Reactive ion etching (RIE) imatanthawuza njira yomwe tinthu tating'onoting'ono tating'onoting'ono ndi ma ion omwe amalowetsedwa amatenga nawo mbali pakuchitapo kanthu nthawi imodzi. Pakati pawo, tinthu tating'onoting'ono tating'onoting'ono tating'onoting'ono (omwe timatchedwanso free radicals), okhala ndi ndende yayikulu (pafupifupi 1% mpaka 10% ya ndende ya gasi), zomwe ndizo zikuluzikulu za etchant. The mankhwala opangidwa ndi zochita mankhwala pakati pawo ndi zinthu Zokhazikika mwina volatilized ndi mwachindunji yotengedwa m'chipinda anachita, kapena anasonkhanitsa pamwamba Zokhazikika; pamene ma ion omwe amaperekedwa ali pamlingo wocheperako (10-4 mpaka 10-3 wa ndende ya gasi), ndipo amafulumizitsidwa ndi gawo lamagetsi la ion sheath lomwe limapangidwa pamwamba pa mtandawo kuti liphulitse malo okhazikika. Pali ntchito ziwiri zazikulu za tinthu tating'onoting'ono. Chimodzi ndi kuwononga kapangidwe ka atomiki ya zinthu zokhazikika, potero kufulumizitsa mlingo umene tinthu tating'onoting'ono timachita nawo; wina ndi bombard ndi kuchotsa anasonkhanitsa anachita mankhwala kuti Etched zakuthupi ndi zonse kukhudzana ndi yogwira particles, kuti etching akupitiriza.

Chifukwa ma ion satenga nawo gawo mwachindunji pakuchitapo kanthu (kapena kuwerengera gawo laling'ono kwambiri, monga kuchotsa bombardment ndi kukhetsa mwachindunji kwa ma ion), kunena mosapita m'mbali, njira yolumikizira pamwambapa iyenera kutchedwa etching-assisted ion. Dzina loti reactive ion etching silolondola, koma likugwiritsidwabe ntchito mpaka pano. Zida zoyambirira za RIE zidagwiritsidwa ntchito m'ma 1980. Chifukwa chogwiritsa ntchito magetsi amtundu umodzi wa RF komanso mawonekedwe osavuta achipinda, imakhala ndi malire malinga ndi kuchuluka kwa etching, kufanana komanso kusankha.

4.4 Maginito Owonjezera Zida Zopangira Ma Ion

Chipangizo cha MERIE (Magnetically Enhanced Reactive Ion Etching) ndi chipangizo cholumikizira chomwe chimapangidwa powonjezera mphamvu ya maginito ya DC ku chipangizo chalathyathyathya cha RIE ndipo cholinga chake ndi kukulitsa kuchuluka kwa etching.

Zipangizo za MERIE zidagwiritsidwa ntchito kwambiri m'zaka za m'ma 1990, pomwe zida zowotchera zamtundu umodzi zidakhala zida zodziwika bwino pamsika. Choyipa chachikulu cha zida za MERIE ndikuti kugawa kwapang'onopang'ono kwa ndende ya plasma chifukwa cha maginito kumabweretsa kusiyana kwapano kapena magetsi pa chipangizo chophatikizika, potero kuwononga chipangizocho. Popeza kuwonongeka kumeneku kumayambitsidwa ndi inhomogeneity nthawi yomweyo, kuzungulira kwa maginito sikungathe kuthetsa. Kukula kwa mabwalo ophatikizika kukupitilira kuchepa, kuwonongeka kwa zida zawo kukuchulukirachulukira ku inhomogeneity ya plasma, ndipo ukadaulo wowonjezera kuchuluka kwa ma etching mwa kukulitsa mphamvu ya maginito pang'onopang'ono wasinthidwa ndi ukadaulo wa ma RF ambiri opangira ma planar reactive ion etching technology. ndi, luso lophatikizana bwino la plasma etching.

4.5 Zida zophatikizika bwino za plasma

Capacitively coupled plasma (CCP) etching equipment ndi chipangizo chomwe chimapanga madzi a m'magazi mu chipinda chochitirapo kanthu kudzera pa capacitive coupling pogwiritsa ntchito ma radio frequency (kapena DC) magetsi pa mbale ya electrode ndipo amagwiritsidwa ntchito polumikizira. Mfundo yake yojambulira ndi yofanana ndi zida zopangira ma ion etching.

Chithunzi chosavuta cha zida za CCP etching chikuwonetsedwa pansipa. Nthawi zambiri amagwiritsa ntchito magwero awiri kapena atatu a RF a ma frequency osiyanasiyana, ndipo ena amagwiritsanso ntchito magetsi a DC. Mafupipafupi amagetsi a RF ndi 800kHz ~ 162MHz, ndipo omwe amagwiritsidwa ntchito kwambiri ndi 2MHz, 4MHz, 13MHz, 27MHz, 40MHz ndi 60MHz. Magetsi a RF okhala ndi ma frequency a 2MHz kapena 4MHz nthawi zambiri amatchedwa magwero otsika a RF. Nthawi zambiri amalumikizidwa ndi electrode yapansi pomwe pali chotupa. Ndiwothandiza kwambiri pakuwongolera mphamvu ya ion, motero amatchedwanso mphamvu za bias; Mphamvu zamagetsi za RF zokhala ndi ma frequency pamwamba pa 27MHz zimatchedwa magwero apamwamba a RF. Amatha kulumikizidwa ndi electrode yapamwamba kapena electrode yapansi. Ndiwothandiza kwambiri pakuwongolera ndende ya plasma, motero amatchedwanso magwero amagetsi. Mphamvu yamagetsi ya 13MHz RF ili pakati ndipo nthawi zambiri imawonedwa kuti ili ndi ntchito zonse pamwambapa koma ndizochepa. Dziwani kuti ngakhale kuchuluka kwa plasma ndi mphamvu zitha kusinthidwa mumtundu wina ndi mphamvu ya RF magwero osiyanasiyana (otchedwa decoupling effect), chifukwa cha mawonekedwe a capacitive coupling, sangathe kusinthidwa ndikuwongoleredwa kwathunthu paokha.

Kugawa mphamvu kwa ma ion kumakhudza kwambiri magwiridwe antchito atsatanetsatane a etching ndi kuwonongeka kwa chipangizocho, chifukwa chake chitukuko chaukadaulo kuti chiwongolere kugawa mphamvu kwa ion chakhala chimodzi mwazinthu zofunika kwambiri pazida zotsogola. Pakadali pano, matekinoloje omwe agwiritsidwa ntchito bwino popanga akuphatikiza ma multi-RF hybrid drive, DC superposition, RF ophatikizidwa ndi DC pulse bias, ndi synchronous pulsed RF kutulutsa kwamagetsi okondera komanso magetsi oyambira.

CCP etching zida ndi imodzi mwa mitundu iwiri yogwiritsidwa ntchito kwambiri ya plasma etching zida. Amagwiritsidwa ntchito kwambiri popanga zida za dielectric, monga chipata chakumbali ndi chigoba cholimba kutsogolo kwa logic chip process, etching ya dzenje lapakati, mosaic ndi aluminium pad etching kumbuyo, komanso kutsekera kwa ngalande zakuya, mabowo akuya ndi mabowo olumikizana ndi ma waya mu 3D flash memory chip process (kutenga silicon nitride/silicon oxide structure monga chitsanzo).

Pali zovuta ziwiri zazikulu ndi njira zowongolera zomwe zida za CCP zimakumana nazo. Choyamba, pakugwiritsa ntchito mphamvu ya ion yokwera kwambiri, kuthekera kokhazikika kwazinthu zazikuluzikulu (monga dzenje ndi kutsekera kwa 3D flash memory kumafuna chiyerekezo choposa 50:1). Njira yamakono yowonjezerera mphamvu yokondera kuti iwonjezere mphamvu ya ion yagwiritsa ntchito magetsi a RF mpaka 10,000 watts. Poona kuchuluka kwa kutentha komwe kumapangidwa, ukadaulo woziziritsa komanso kutentha kwa chipinda chochitiramo uyenera kukonzedwa mosalekeza. Chachiwiri, pakufunika kutsogola pakupanga mpweya watsopano wa etching kuti athetse vuto la etching.

4.6 Zida Zophatikizana Zophatikizana ndi Plasma Etching

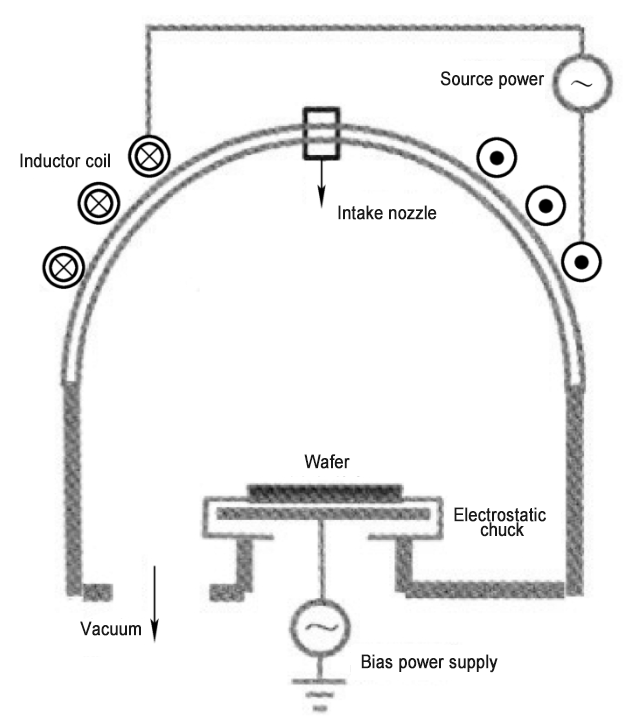

Inductively coupled plasma (ICP) etching equipment ndi chipangizo chomwe chimagwirizanitsa mphamvu ya ma radio frequency power source mu chipinda chochitiramo ngati mphamvu ya maginito kudzera pa inductor coil, potero imapanga madzi a m'magazi kuti alowemo. Mfundo yake etching imakhalanso ya generalized reactive ion etching.

Pali mitundu iwiri yayikulu yamapangidwe amtundu wa plasma pazida za ICP etching. Imodzi ndi ukadaulo wophatikizana ndi plasma (TCP) wopangidwa ndikupangidwa ndi Lam Research. Coil yake ya inductor imayikidwa pa ndege yawindo la dielectric pamwamba pa chipinda chochitira. Chizindikiro cha 13.56MHz RF chimapanga mphamvu ya maginito yosinthira mu koyilo yomwe ili pafupi ndi zenera la dielectric ndipo imasiyanitsidwa mozungulira ndi koyilo ya koyilo ngati pakatikati.

Mphamvu ya maginito imalowa m'chipinda chochitiramo kudzera pawindo la dielectric, ndipo mphamvu yamagetsi yosinthira imapanga malo osinthika amagetsi ofananira ndi zenera la dielectric muchipinda chochitiramo, potero amakwaniritsa kupasuka kwa mpweya wotsekemera ndikutulutsa plasma. Popeza mfundoyi imatha kumveka ngati thiransifoma yokhala ndi coil yopangira inductor ngati poyambira poyambira komanso plasma m'chipinda chochitiramo ngati mafunde achiwiri, etching ya ICP imatchedwa izi.

Ubwino waukulu waukadaulo wa TCP ndikuti kapangidwe kake ndi kosavuta kukulitsa. Mwachitsanzo, kuchokera ku 200mm wafer kupita ku 300mm wafer, TCP imatha kukhalabe ndi mawonekedwe omwewo pongowonjezera kukula kwa koyilo.

Mapangidwe enanso a plasma ndi ukadaulo wa decoupled plasma source (DPS) wopangidwa ndi kupangidwa ndi Applied Materials, Inc. ya ku United States. Coil yake ya inductor imakhala ndi mawonekedwe atatu pawindo la hemispherical dielectric. Mfundo yopangira plasma ndi yofanana ndi teknoloji ya TCP yomwe tatchulayi, koma kuyendetsa bwino kwa gasi ndikokwera kwambiri, komwe kumapangitsa kuti munthu apeze kuchuluka kwa plasma.

Popeza mphamvu ya kuphatikizika kwa inductive kupanga plasma ndi yayikulu kuposa ya capacitive coupling, ndipo plasma imapangidwa makamaka m'dera lomwe lili pafupi ndi zenera la dielectric, kuchuluka kwake kwa plasma kumatsimikiziridwa ndi mphamvu ya gwero lamagetsi lomwe limalumikizidwa ndi inductor. coil, ndipo mphamvu ya ion mu sheath ya ion pamwamba pa chowotchayo imatsimikiziridwa ndi mphamvu yamagetsi opangira kukondera, kotero ndende ndi mphamvu za ayoni. ikhoza kuyendetsedwa paokha, potero kukwaniritsa kugwirizanitsa.

ICP etching zida ndi imodzi mwamitundu iwiri yomwe imagwiritsidwa ntchito kwambiri pazida za plasma etching. Amagwiritsidwa ntchito kwambiri poyika ma silicon osaya, germanium (Ge), zida zapolysilicon pachipata, zida zachitsulo, silicon (Strained-Si), mawaya achitsulo, zitsulo zachitsulo (Pads), masks achitsulo olimba a mosaic ndi njira zingapo ukadaulo wojambula zithunzi.

Kuphatikiza apo, ndi kukwera kwa mabwalo ophatikizika amitundu itatu, masensa azithunzi a CMOS ndi makina amagetsi amagetsi ang'onoang'ono (MEMS), komanso kuchuluka kwachangu kwakugwiritsa ntchito kudzera pa silicon vias (TSV), mabowo akulu akulu ndi silicon etching yakuya yokhala ndi ma morphologies osiyanasiyana, opanga ambiri adayambitsa zida zomangira zomwe zidapangidwa makamaka kuti zigwiritsidwe ntchito. Makhalidwe ake ndi kuzama kwakukulu kwa etching (makumi kapena mazana a ma microns), choncho imagwira ntchito kwambiri pansi pa kutuluka kwa mpweya wambiri, kuthamanga kwambiri komanso mphamvu zambiri.

—————————————————————————————————————————————————— ————————————-

Semicera ikhoza kuperekazigawo za graphite, zofewa/zokhazikika, zida za silicon carbide, Zigawo za CVD silicon carbide,ndiZigawo zokutira za SiC/TaCndi m'masiku 30.

Ngati mukufuna zinthu za semiconductor pamwambapa,chonde musazengereze kulumikizana nafe nthawi yoyamba.

Tel: +86-13373889683

Watsapp: +86-15957878134

Email: sales01@semi-cera.com

Nthawi yotumiza: Aug-31-2024