Chidule Chimodzi

Mu njira yophatikizira yopangira dera, photolithography ndiye njira yayikulu yomwe imatsimikizira kuchuluka kwa mabwalo ophatikizika. Ntchito ya njirayi ndikutumiza mokhulupirika ndikusamutsa zidziwitso zojambulidwa kuchokera ku chigoba (chomwe chimatchedwanso chigoba) kupita ku gawo lapansi la semiconductor.

Mfundo yaikulu ya ndondomeko ya photolithography ndiyo kugwiritsa ntchito photochemical reaction ya photoresist yokutidwa pamwamba pa gawo lapansi kuti ajambule mawonekedwe a dera pa chigoba, potero kukwaniritsa cholinga chosamutsa dongosolo lophatikizika kuchokera ku mapangidwe kupita ku gawo lapansi.

Njira yoyambira ya Photolithography

Choyamba, photoresist imagwiritsidwa ntchito pamtunda wapansi pogwiritsa ntchito makina opaka;

Kenako, makina a photolithography amagwiritsidwa ntchito powonetsa gawo lapansi lophimbidwa ndi photoresist, ndipo njira ya photochemical reaction imagwiritsidwa ntchito polemba chidziwitso cha chigoba chomwe chimafalitsidwa ndi makina a photolithography, kumaliza kufalitsa kukhulupirika, kusamutsa ndi kubwereza kwa chigoba ku gawo lapansi;

Pomaliza, wokonza mapulogalamu amagwiritsidwa ntchito kupanga gawo lapansi lowonekera kuti achotse (kapena kusunga) chojambula chojambula chomwe chimapangidwa ndi photochemical reaction pambuyo pakuwonekera.

Njira yachiwiri ya Photolithography

Kuti musamutse mawonekedwe ozungulira opangidwa pa chigoba kupita ku chowotcha cha silicon, kutengerako kuyenera kuchitika koyamba kudzera munjira yowonekera, ndiyeno mawonekedwe a silicon ayenera kupezedwa kudzera munjira yolumikizira.

Popeza kuunikira kwa malo opangira photolithography kumagwiritsa ntchito kuwala kwachikasu komwe zinthu zowoneka bwino sizikumva, zimatchedwanso malo achikasu.

Photolithography idagwiritsidwa ntchito koyamba m'makampani osindikizira ndipo inali ukadaulo waukulu wopanga ma PCB oyambirira. Kuyambira m'ma 1950s, kujambula zithunzi pang'onopang'ono kwakhala ukadaulo wotsogola wosinthira mawonekedwe pakupanga IC.

Zizindikiro zazikulu za ndondomeko ya lithography ndi monga kuthetsa, kukhudzidwa, kulondola kwapamwamba, kuchuluka kwa chilema, ndi zina zotero.

Chinthu chofunika kwambiri pa ndondomeko ya photolithography ndi photoresist, yomwe ndi chithunzithunzi. Popeza kukhudzika kwa photoresist kumadalira kutalika kwa gwero la kuwala, zipangizo zosiyanasiyana za photoresist zimafunika pa njira za photolithography monga g/i line, 248nm KrF, ndi 193nm ArF.

Njira yaikulu ya ndondomeko ya photolithography imaphatikizapo masitepe asanu

:

-Base filimu kukonzekera;

-Ikani photoresist ndi kuphika zofewa;

- Kuyanjanitsa, kuwonetseredwa ndi kuphika pambuyo pakuwonekera;

- Pangani filimu yolimba;

-Kuzindikira chitukuko.

(1)Base filimu kukonzekera: makamaka kuyeretsa ndi kutaya madzi m'thupi. Chifukwa zodetsa zilizonse zimatha kufooketsa kumamatira pakati pa photoresist ndi chophatikizira, kuyeretsa bwino kumatha kuwongolera kumamatira pakati pa chophatikizira ndi chojambula.

(2)Chophimba cha Photoresist: Izi zimatheka potembenuza chowotcha cha silicon. Ma photoresists osiyanasiyana amafunikira magawo osiyanasiyana okutira, kuphatikiza liwiro lozungulira, makulidwe a photoresist, ndi kutentha.

Kuphika kofewa: Kuphika kumatha kupititsa patsogolo kaphatikizidwe pakati pa photoresist ndi silicon wafer, komanso kufanana kwa makulidwe a photoresist, omwe ndi opindulitsa pakuwongolera bwino kwa miyeso ya geometric ya njira yotsatsira.

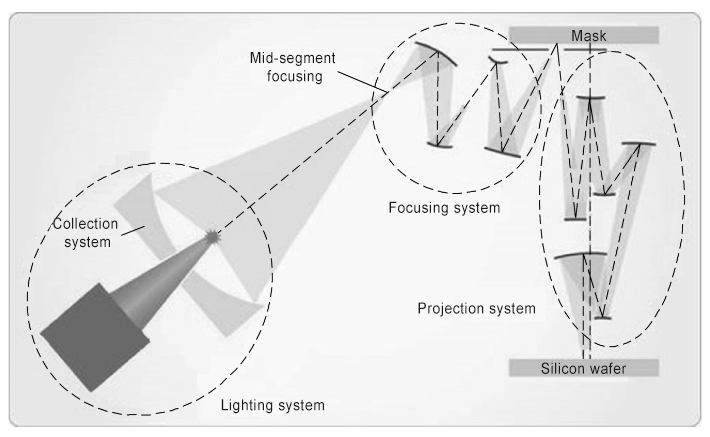

(3)Kuyanjanitsa ndi kuwonekera: Kuyanjanitsa ndi kuwonetseratu ndizofunika kwambiri pa ndondomeko ya photolithography. Amatchulanso kugwirizanitsa mawonekedwe a chigoba ndi mawonekedwe omwe alipo pa chowotcha (kapena mawonekedwe akutsogolo), kenako ndikuwunikira ndi kuwala kwake. Mphamvu ya kuwala imayendetsa zigawo za photosensitive mu photoresist, potero kusamutsa mawonekedwe a chigoba kwa photoresist.

Zida zomwe zimagwiritsidwa ntchito poyanjanitsa ndi kuwonetseredwa ndi makina a photolithography, omwe ndi okwera mtengo kwambiri omwe amagwiritsidwa ntchito popanga makina opangira magetsi. Mulingo waukadaulo wamakina a photolithography umayimira mulingo wakupita patsogolo kwa mzere wonse wopanga.

Kuphika pambuyo powonekera: kumatanthauza njira yophika pang'onopang'ono pambuyo powonekera, yomwe imakhala ndi zotsatira zosiyana ndi zozama za ultraviolet photoresists ndi i-line photoresists wamba.

Kwa photoresist yakuya ya ultraviolet, kuphika pambuyo powonekera kumachotsa zigawo zotetezera mu photoresist, kulola kuti photoresist isungunuke mu mapulogalamuwa, kotero kuphika pambuyo powonekera ndikofunikira;

Pakuti ochiritsira i-mzere photoresists, pambuyo kukhudzana kuphika akhoza kusintha adhesion wa photoresist ndi kuchepetsa kuyimirira mafunde (oyima mafunde adzakhala ndi zotsatira m'mphepete kamangidwe ka photoresist).

(4)Kupanga filimu yovuta: ntchito mapulogalamu kupasuka sungunuka gawo la photoresist (zabwino photoresist) pambuyo kukhudzana, ndi molondola kusonyeza chigoba chitsanzo ndi photoresist chitsanzo.

Zofunika kwambiri pakukula kwa chitukuko ndi kutentha kwachitukuko ndi nthawi, mlingo wa chitukuko ndi kukhazikika, kuyeretsa, ndi zina zotero. kupeza zotsatira zomwe mukufuna.

Kuumitsa kumadziwikanso kuti kuumitsa kuphika, yomwe ndi njira yochotsera zosungunulira zotsalira, mapulogalamu, madzi ndi zigawo zina zotsalira zotsalira mu photoresist yopangidwa ndi Kutentha ndi kutulutsa madzi, kuti apititse patsogolo zomatira za photoresist ku gawo lapansi la silicon. kukana etching kwa photoresist.

Kutentha kwa ndondomeko yowumitsa kumasiyanasiyana malinga ndi ma photoresists osiyanasiyana ndi njira zowumitsa. Cholinga chake ndi chakuti chithunzi cha photoresist sichimasokoneza ndipo photoresist iyenera kukhala yolimba mokwanira.

(5)Kuyendera kwachitukuko: Izi ndi kufufuza zolakwika mu photoresist chitsanzo pambuyo chitukuko. Nthawi zambiri, ukadaulo wozindikiritsa zithunzi umagwiritsidwa ntchito kusanthula kachipangizo ka chip pambuyo pa chitukuko ndikuchifananiza ndi mawonekedwe osungidwa opanda chilema. Ngati kusiyana kulikonse kumapezeka, kumaonedwa kuti ndi kolakwika.

Ngati kuchuluka kwa zolakwika kupitilira mtengo wina, chowotcha cha silicon chimawerengedwa kuti chalephera kuyesa kwachitukuko ndipo chikhoza kuchotsedwa kapena kukonzedwanso momwe kuli koyenera.

Mu njira yophatikizira yopangira dera, njira zambiri sizingasinthidwe, ndipo photolithography ndi imodzi mwazinthu zochepa zomwe zitha kukonzedwanso.

Photomasks atatu ndi zipangizo photoresist

3.1 Photomask

Photomask, yomwe imadziwikanso kuti chigoba cha photolithography, ndiukadaulo womwe umagwiritsidwa ntchito popanga chithunzithunzi chopanga chophatikizira chophatikizika chozungulira.

Njira yopangira ma photomask ndikusintha zidziwitso zoyambira zomwe zimafunikira pakupanga mawafa opangidwa ndi akatswiri ophatikizira ozungulira kukhala mawonekedwe amtundu wa data omwe amatha kudziwika ndi majenereta a laser kapena zida zowunikira ma elekitironi kudzera pakukonza ma data, kuti awululidwe ndi zida pamwamba pa photomask gawo lapansi zinthu yokutidwa ndi photosensitive zakuthupi; ndiye amakonzedwa kudzera munjira zingapo monga chitukuko ndi etching kuti akonze dongosolo pa gawo lapansi; potsiriza, amayesedwa, kukonzedwa, kutsukidwa, ndi filimu-laminated kupanga chigoba mankhwala ndi kuperekedwa kwa Integrated dera wopanga ntchito.

3.2 Wojambula zithunzi

Photoresist, yomwe imadziwikanso kuti photoresist, ndi zinthu zowoneka bwino. The photosensitive zigawo zikuluzikulu mmenemo adzadutsa kusintha mankhwala pansi walitsa wa kuwala, potero kuchititsa kusintha kwa mlingo kuvunda. Ntchito yake yayikulu ndikusamutsa chitsanzo pa chigoba kupita ku gawo lapansi monga chofufumitsa.

Ntchito mfundo photoresist: Choyamba, ndi photoresist yokutidwa pa gawo lapansi ndi chisanadze anaphika kuchotsa zosungunulira;

Kachiwiri, chigobacho chimawonekera pakuwala, zomwe zimapangitsa kuti zigawo za photosensitive zomwe zili mu gawo lowonekera zichitike ndi mankhwala;

Kenako, kuphika pambuyo powonekera kumachitika;

Potsirizira pake, photoresist imasungunuka pang'ono kupyolera mu chitukuko (kwa photoresist yabwino, malo owonekera amasungunuka; chifukwa cha photoresist yoipa, malo osadziwika amasungunuka), potero akuzindikira kusamutsidwa kwa kayendetsedwe ka dera lophatikizidwa kuchokera ku chigoba kupita ku gawo lapansi.

Zigawo za photoresist makamaka monga filimu kupanga utomoni, photosensitive chigawo chimodzi, kufufuza zina ndi zosungunulira.

Pakati pawo, utomoni wopangira filimu umagwiritsidwa ntchito popereka zinthu zamakina ndi kukana etching; chigawo cha photosensitive chimadutsa kusintha kwa mankhwala pansi pa kuwala, kuchititsa kusintha kwa chiwerengero cha kusungunuka;

Kufufuza zowonjezera kumaphatikizapo utoto, zowonjezera kukhuthala, ndi zina zotero, zomwe zimagwiritsidwa ntchito popititsa patsogolo ntchito ya photoresist; zosungunulira zimagwiritsidwa ntchito kusungunula zigawozo ndikusakaniza mofanana.

The photoresists panopa ntchito kwambiri akhoza kugawidwa mu photoresists chikhalidwe ndi photoresists mankhwala amplified malinga photochemical reaction limagwirira, ndipo akhoza kugawidwa mu ultraviolet, deep ultraviolet, kwambiri ultraviolet, elekitironi mtengo, ion mtengo ndi X-ray photoresists malinga ndi kutalika kwa mawonekedwe a photosensitivity.

Zida zinayi zojambula zithunzi

Ukadaulo wa Photolithography wadutsa munjira ya chitukuko cha kulumikizana/kuyandikira lithography, optical projection lithography, step-and-repeat lithography, scanning lithography, immersion lithography, ndi EUV lithography.

4.1 Kulumikizana / Kuyandikira Lithography Machine

Ukadaulo wolumikizana ndi lithography udawoneka m'ma 1960s ndipo udagwiritsidwa ntchito kwambiri m'ma 1970. Inali njira yayikulu yopangira ma lithography m'nthawi ya mabwalo ang'onoang'ono ophatikizika ndipo idagwiritsidwa ntchito makamaka kupanga mabwalo ophatikizika okhala ndi mawonekedwe akulu kuposa 5μm.

Pamakina olumikizirana / oyandikira lithography, chophatikiziracho nthawi zambiri chimayikidwa pamalo opingasa omwe amawunikiridwa pamanja ndi tebulo lozungulira. Wogwiritsa ntchitoyo amagwiritsa ntchito maikulosikopu yakumunda kuti ayang'ane nthawi imodzi pomwe chigoba ndi chowotcha, ndikuwongolera pamanja malo ogwirira ntchito kuti agwirizanitse chigoba ndi mkate. Pambuyo pa mtanda ndi chigoba zikugwirizana, awiriwo adzapanikizidwa pamodzi kuti chigoba chigwirizane mwachindunji ndi photoresist pamwamba pa mtanda.

Pambuyo pochotsa cholinga cha microscope, chowotcha chophwanyidwa ndi chigoba chimasunthidwa patebulo lowonekera kuti chiwonekere. Kuwala kotulutsidwa ndi nyali ya mercury kumapindika ndikufanana ndi chigoba kudzera pa lens. Popeza chigoba chikugwirizana mwachindunji ndi photoresist wosanjikiza pa mtanda, chigoba chitsanzo anasamutsa photoresist wosanjikiza pa chiŵerengero cha 1: 1 pambuyo kukhudzana.

Zida zolumikizirana ndi lithography ndi zida zosavuta komanso zotsika mtengo kwambiri, ndipo zimatha kukwaniritsa mawonekedwe azithunzi zazing'ono za micron, kotero zimagwiritsidwabe ntchito popanga zinthu zazing'ono komanso kafukufuku wa labotale. Pakupanga kwakukulu kophatikizika kophatikizana, ukadaulo wa proximity lithography udayambitsidwa kuti apewe kukwera kwamitengo ya lithography chifukwa cholumikizana mwachindunji pakati pa chigoba ndi chowotcha.

Proximity lithography idagwiritsidwa ntchito kwambiri m'zaka za m'ma 1970 panthawi ya mabwalo ang'onoang'ono ophatikizika komanso nthawi yoyambirira ya mabwalo ophatikizika apakatikati. Mosiyana kukhudzana lithography, chigoba moyandikana lithography si kukhudzana mwachindunji ndi photoresist pa mphika, koma kusiyana wodzazidwa nayitrogeni watsala. Chigobacho chimayandama pa nayitrogeni, ndipo kukula kwa kusiyana pakati pa chigoba ndi mtanda kumatsimikiziridwa ndi mphamvu ya nayitrogeni.

Popeza palibe kulumikizana kwachindunji pakati pa chophatikizika ndi chigoba pafupi ndi lithography, zolakwika zomwe zimayambitsidwa panthawi ya lithography zimachepetsedwa, potero zimachepetsa kutayika kwa chigoba ndikuwongolera zokolola za mkate. Pafupi ndi lithography, kusiyana pakati pa chophika ndi chigoba kumayika chophikacho m'chigawo cha Fresnel diffraction. Kukhalapo kwa diffraction kumalepheretsa kupititsa patsogolo kukonzanso kwa zida zoyandikana ndi lithography, kotero lusoli ndiloyenera kupanga mabwalo ophatikizika okhala ndi mawonekedwe apamwamba kuposa 3μm.

4.2 Stepper ndi Repeater

The stepper ndi chimodzi mwa zida zofunika kwambiri m'mbiri ya wafer lithography, zomwe zalimbikitsa njira ya sub-micron lithography kuti ikhale yochuluka. The stepper ntchito mmene malo amodzi kukhudzana kukhudzana 22mm × 22mm ndi kuwala projekiti mandala ndi kuchepetsa chiŵerengero cha 5: 1 kapena 4: 1 kusamutsa chitsanzo pa chigoba kwa chophatika.

Makina opangira ma step-and-repeat lithography nthawi zambiri amakhala ndi mawonekedwe owonekera, malo ogwirira ntchito, gawo lachigoba, gawo laling'ono, loyang'ana, kagawo kakang'ono, kagawo kakang'ono, kagawo kakang'ono, kagawo kakang'ono, kagawo kakang'ono kosinthira chigoba. , pulogalamu yamagetsi, ndi pulogalamu yaying'ono.

Zomwe zimagwirira ntchito pamakina opangira masitepe ndi kubwereza ndi motere:

Choyamba, chophwanyika chophimbidwa ndi photoresist chimasamutsidwa ku tebulo la workpiece pogwiritsa ntchito kachipangizo kakang'ono, ndipo chigoba chowululidwa chimasamutsidwa ku tebulo la chigoba pogwiritsa ntchito njira yosinthira chigoba;

Kenako, kachitidweko kamagwiritsa ntchito kagawo kakang'ono koyang'ana / kusanja kuti apange miyeso ya kutalika kwa mfundo zingapo pa chowotcha pagawo la workpiece kuti apeze zambiri monga kutalika ndi kupendekeka kwa pamwamba pa chopindikacho kuti chiwonekere, kuti malo owonekera awonekere. chowotchacho chimatha kuyendetsedwa nthawi zonse mkati mwa kuya kwa cholinga chowonetsera panthawi yowonekera;Pambuyo pake, makinawa amagwiritsa ntchito njira yolumikizirana kuti agwirizane ndi chigoba ndi chowotcha kuti panthawi yowonekera, kulondola kwa chithunzi cha chigoba ndi kusamutsidwa kwa mawonekedwe opindika nthawi zonse kumakhala mkati mwazofunikira zokutira.

Pomaliza, gawo-ndi-kuwonetseredwa mchitidwe lonse yopyapyala pamwamba anamaliza molingana ndi njira kuzindikiritsa ntchito kusamutsa chitsanzo.

Makina otsatirawa a stepper ndi scanner lithography amatengera zomwe zili pamwambazi, kuwongolera masitepe → kuyang'ana pa sikani → kuwonekera, ndi kuyang'ana / kusanja → kuyanjanitsa → kuwonekera pamitundu iwiri yoyezera (kuyang'ana / kusanja → kuyanjanitsa) ndi kusanthula kuwonetseredwa mu kufanana.

Poyerekeza ndi sitepe-ndi-scan lithography makina, sitepe-ndi-kubwereza lithography makina safuna kukwaniritsa synchronous n'zosiyana kupanga sikani za chigoba ndi yopyapyala, ndipo sikutanthauza kupanga sikani chigoba tebulo ndi synchronous kupanga sikani dongosolo dongosolo. Choncho, mapangidwe ake ndi ophweka, mtengo wake ndi wochepa, ndipo ntchitoyo ndi yodalirika.

Pambuyo ukadaulo wa IC udalowa 0.25μm, kugwiritsa ntchito masitepe-ndi-kubwereza lithography kunayamba kuchepa chifukwa cha ubwino wa sitepe-ndi-scan lithography pakusanthula kukula kwa munda ndi kufanana. Pakadali pano, zojambula zaposachedwa ndi zobwerezabwereza zoperekedwa ndi Nikon zili ndi mawonekedwe osasunthika monga momwe zimawonera masitepe ndi sikani, ndipo zimatha kukonza ma wafers opitilira 200 pa ola limodzi, ndikupanga bwino kwambiri. Makina amtundu uwu wa lithography pakadali pano amagwiritsidwa ntchito makamaka popanga zigawo zosafunikira za IC.

4.3 Stepper Scanner

Kugwiritsa ntchito masitepe-ndi-scan lithography kudayamba mu 1990s. Pakukonza magwero a kuwala kosiyanasiyana, ukadaulo wa sitepe ndi sikani utha kuthandizira njira zosiyanasiyana zaukadaulo, kuyambira 365nm, 248nm, 193nm kumizidwa mpaka EUV lithography. Mosiyana ndi sitepe-ndi-kubwereza lithography, kukhudzana single-munda wa sitepe-ndi-scan lithography utenga zazikulu kupanga sikani, ndiko kuti, chigoba mbale amamaliza sikani mayendedwe synchronously wachibale ndi yopyapyala; pambuyo pakali pano kukhudzana ndi munda anamaliza, yopyapyala amanyamulidwa ndi workpiece siteji ndi analowa lotsatira sikani kumunda udindo, ndi kukhudzana mobwerezabwereza akupitiriza; bwerezani kuwonetsa masitepe-ndi-scan kangapo mpaka magawo onse a mtanda wonsewo atawonekera.

Pokonzekera mitundu yosiyanasiyana ya magetsi (monga i-line, KrF, ArF), stepper-scanner imatha kuthandizira pafupifupi ma node onse aukadaulo a semiconductor kutsogolo-kumapeto. Njira zodziwika bwino za silicon-based CMOS zatengera masikanidwe okwera kwambiri kuyambira 0.18μm node; makina amphamvu kwambiri a ultraviolet (EUV) omwe amagwiritsidwa ntchito pano m'malo ochepera 7nm amagwiritsanso ntchito kusanthula kwa stepper. Pambuyo pa kusinthidwa pang'ono, chojambulira cha stepper chingathenso kuthandizira kafukufuku ndi chitukuko ndi kupanga njira zambiri zopanda silicon monga MEMS, zipangizo zamagetsi, ndi zipangizo za RF.

Akuluakulu opanga makina a step-and-scan lithography akuphatikizapo ASML (Netherlands), Nikon (Japan), Canon (Japan) ndi SMEE (China). ASML inayambitsa makina a TWINSCAN a makina opangira masitepe-ndi-scan mu 2001. Imatengera zomangamanga zamagulu awiri, zomwe zingathe kupititsa patsogolo kutulutsa kwa zidazo ndipo zakhala makina ogwiritsidwa ntchito kwambiri omwe amagwiritsidwa ntchito kwambiri.

4.4 Kumiza Lithography

Zitha kuwonedwa kuchokera ku njira ya Rayleigh kuti, pamene mawonekedwe a kutalika kwa mawonekedwe akukhalabe osasinthika, njira yabwino yopititsira patsogolo kusintha kwa kujambula ndikuwonjezera chiwerengero cha chiwerengero cha makina ojambula. Pazosankha zofananira pansi pa 45nm ndi kupitilira apo, njira ya ArF yowuma singathenso kukwaniritsa zofunikira (chifukwa imathandizira kukhazikika kwazithunzi za 65nm), kotero ndikofunikira kuyambitsa njira yomiza lithography. Muukadaulo waukadaulo waukadaulo, sing'anga pakati pa mandala ndi photoresist ndi mpweya, pomwe ukadaulo womiza lithography umalowa m'malo mwa sing'anga ya mpweya ndi madzi (nthawi zambiri madzi a ultrapure okhala ndi cholozera cha 1.44).

M'malo mwake, ukadaulo womiza lithography umagwiritsa ntchito kufupikitsa kutalika kwa gwero la kuwala pambuyo poti kuwala kumadutsa mumadzimadzi kuti apititse patsogolo kusamvana, ndipo kufupikitsa chiŵerengero ndi refractive index ya sing'anga yamadzi. Ngakhale makina omiza a lithography ndi mtundu wa makina a sitepe-ndi-scan lithography, ndipo njira yothetsera zida zake sizinasinthe, ndikusintha ndi kukulitsa makina a ArF step-and-scan lithography chifukwa cha kukhazikitsidwa kwa matekinoloje ofunikira kumizidwa.

Ubwino wa kumiza lithography ndikuti, chifukwa cha kuchuluka kwa kabowo ka manambala a dongosolo, kuthekera kwa kujambula kwa makina a stepper-scanner lithography kumapangidwa bwino, komwe kumatha kukwaniritsa zofunikira zakusintha kwazithunzi pansipa 45nm.

Popeza makina omiza lithography akugwiritsabe ntchito gwero la kuwala kwa ArF, kupitiliza kwa njirayi ndikotsimikizika, kupulumutsa mtengo wa R&D wa gwero la kuwala, zida ndi njira. Pazifukwa izi, kuphatikiza zithunzi zingapo komanso ukadaulo wowerengera, makina omiza a lithography angagwiritsidwe ntchito pamagawo a 22nm ndi pansi. Makina a EUV lithography asanakhazikitsidwe mwalamulo kupanga makina ambiri, makina omiza a lithography anali atagwiritsidwa ntchito kwambiri ndipo amatha kukwaniritsa zofunikira za 7nm node. Komabe, chifukwa cha kukhazikitsidwa kwa madzi omiza, zovuta zaumisiri wa zida zomwezo zakula kwambiri.

Ukadaulo wake wofunikira umaphatikizapo ukadaulo womiza wamadzimadzi komanso ukadaulo wobwezeretsa, ukadaulo wa kumiza madzimadzi kumunda, kuipitsidwa kwa lithography ndiukadaulo wowongolera chilema, kukonza ndi kukonza magalasi omiza opitilira muyeso, komanso ukadaulo wodziwikiratu pamikhalidwe yomizidwa.

Pakadali pano, makina a ArFi step-and-scan lithography amaperekedwa makamaka ndi makampani awiri, omwe ndi ASML yaku Netherlands ndi Nikon waku Japan. Pakati pawo, mtengo wa ASML NXT1980 Di imodzi ndi pafupifupi ma euro 80 miliyoni.

4.5 Makina Owonjezera a Ultraviolet Lithography

Pofuna kukonza kusintha kwa photolithography, kutalika kwa mawonekedwe kumafupikitsidwanso pambuyo potengera kuwala kwa excimer, ndipo kuwala koopsa kwa ultraviolet ndi kutalika kwa 10 mpaka 14 nm kumayambitsidwa ngati gwero la kuwala. Kutalika kwa kuwala kwa ultraviolet kwadzaoneni ndi kwaufupi kwambiri, ndipo mawonekedwe owoneka bwino omwe angagwiritsidwe ntchito nthawi zambiri amakhala ndi ma multilayer film reflectors monga Mo/Si kapena Mo/Be.

Pakati pawo, chiwonetsero chapamwamba kwambiri cha filimu ya Mo/Si multilayer mu wavelength ya 13.0 mpaka 13.5nm ndi pafupifupi 70%, ndipo chiwonetsero chapamwamba kwambiri cha filimu ya Mo/Be multilayer pamafunde amfupi a 11.1nm ndi pafupifupi 80%. Ngakhale kuwunikira kwa zowonetsera mafilimu a Mo/Be multilayer ndikwambiri, Khalani ndi poizoni kwambiri, kotero kafukufuku wazinthu zotere adasiyidwa popanga ukadaulo wa EUV lithography.Ukadaulo wamakono wa EUV lithography umagwiritsa ntchito filimu ya Mo/Si multilayer, ndipo mawonekedwe ake akuwonekeranso kuti akhale 13.5nm.

Gwero lalikulu la kuwala kwa ultraviolet limagwiritsa ntchito ukadaulo wopangidwa ndi laser-produced plasma (LPP), womwe umagwiritsa ntchito ma laser okwera kwambiri kuti asangalatse madzi a m'magazi a Sn kuti atulutse kuwala. Kwa nthawi yayitali, mphamvu ndi kupezeka kwa gwero lounikira kwakhala zopinga zomwe zikulepheretsa makina a EUV lithography. Kudzera muukadaulo wa master oscillator power amplifier, predictive plasma (PP) ukadaulo woyeretsera magalasi otolera mu-situ, mphamvu ndi kukhazikika kwa magwero a kuwala kwa EUV zasinthidwa kwambiri.

Makina a EUV lithography amapangidwa makamaka ndi magawo ang'onoang'ono monga gwero la kuwala, kuyatsa, ma lens, malo ogwirira ntchito, siteji ya chigoba, kuyanjanitsa kwa wafer, kuyang'ana / kusanja, kutumiza chigoba, kutumiza kwa wafer, ndi chimango cha vacuum. Pambuyo podutsa muzitsulo zounikira zomwe zimapangidwa ndi zonyezimira zosanjikiza zambiri, kuwala koopsa kwa ultraviolet kumayatsidwa pa chigoba chonyezimira. Kuwala komwe kumawonetsedwa ndi chigoba kumalowa mu mawonekedwe owoneka bwino owoneka bwino omwe amapangidwa ndi zowunikira zingapo, ndipo pamapeto pake chithunzi chowoneka bwino cha chigobacho chikuwonetsedwa pamwamba pa chophikacho pamalo opanda mpweya.

Mawonekedwe a makina a EUV lithography onse ndi owoneka ngati arc, ndipo njira yosanthula pang'onopang'ono imagwiritsidwa ntchito kuti ikwaniritse mawonekedwe onse opindika kuti apititse patsogolo kuchuluka kwa zotulutsa. Makina apamwamba kwambiri a ASML a NXE mndandanda wa EUV lithography amagwiritsa ntchito gwero lounikira lokhala ndi kutalika kwa 13.5nm, chigoba chowoneka bwino (6° oblique incidence), njira ya 4x yochepetsera yowunikira yowunikira yokhala ndi 6-mirror structure (NA=0.33), a sikani malo owonera 26mm × 33mm, ndi malo owonetsera vacuum.

Poyerekeza ndi makina omiza lithography, mawonekedwe amodzi a makina a EUV lithography omwe amagwiritsa ntchito magwero a kuwala kwa ultraviolet kwasintha kwambiri, zomwe zingathe kupeŵa njira yovuta yofunikira kuti ma photolithography angapo apange zithunzi zapamwamba kwambiri. Pakalipano, kusamvana kwapang'onopang'ono kwa makina a lithography a NXE 3400B omwe ali ndi chiwerengero cha 0.33 kufika ku 13nm, ndipo mlingo wotuluka umafika 125 zidutswa / h.

Kuti tikwaniritse zofunikira pakukulitsanso Chilamulo cha Moore, m'tsogolomu, makina a EUV opangira ma lithography okhala ndi manambala obowola a 0.5 atenga njira yolozera yomwe ili ndi kutsekereza kwapakati, pogwiritsa ntchito kukulitsa kwa 0.25 times/0.125, ndi Mawonekedwe a sikani adzachepetsedwa kuchoka pa 26m × 33mm mpaka 26mm × 16.5mm, ndi kusamvana kumodzi kumatha kufika pansi pa 8nm.

—————————————————————————————————————————————————— ————————————

Semicera ikhoza kuperekazigawo za graphite, zofewa/zokhazikika, zida za silicon carbide, Zigawo za CVD silicon carbide,ndiZigawo zokutira za SiC/TaCndi njira yonse ya semiconductor m'masiku 30.

Ngati mukufuna zinthu za semiconductor pamwambapa,chonde musazengereze kulumikizana nafe nthawi yoyamba.

Tel: +86-13373889683

Watsapp: +86-15957878134

Email: sales01@semi-cera.com

Nthawi yotumiza: Aug-31-2024