Chidule cha Semiconductor Process

Njira ya semiconductor imakhudzanso kugwiritsa ntchito matekinoloje a microfabrication ndi makanema kuti alumikizane bwino tchipisi ndi zinthu zina m'magawo osiyanasiyana, monga magawo ndi mafelemu. Izi zimathandizira kuchotsedwa kwa ma terminals otsogolera ndi kutsekereza ndi pulasitiki yotchingira sing'anga kuti ipange chophatikizika chonse, chowonetsedwa ngati mawonekedwe azithunzi zitatu, pomaliza kumaliza kuyika kwa semiconductor. Lingaliro la njira ya semiconductor limakhudzanso kutanthauzira kocheperako kwa phukusi la semiconductor chip. Kuchokera pamalingaliro ochulukirapo, amatanthauza uinjiniya wamapaketi, womwe umaphatikizapo kulumikiza ndi kukonza gawo lapansi, kukonza zida zamagetsi zofananira, ndikupanga dongosolo lathunthu logwira ntchito mwamphamvu.

Semiconductor Packaging process Flow

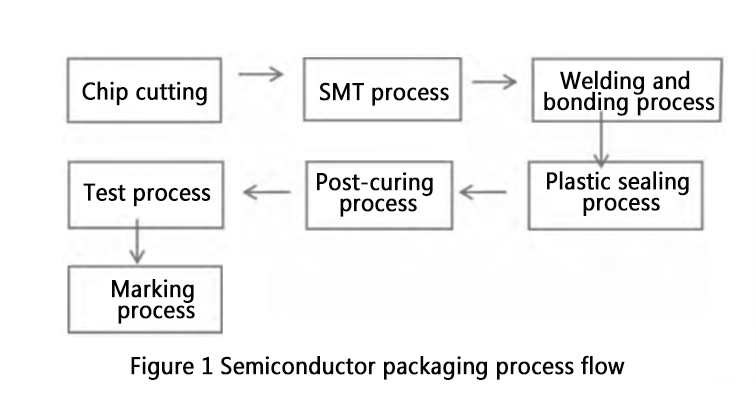

Njira yopangira ma semiconductor imaphatikizapo ntchito zambiri, monga momwe tawonetsera mu Chithunzi 1. Ndondomeko iliyonse imakhala ndi zofunikira zenizeni komanso zoyendera zogwirizana kwambiri, zomwe zimafuna kusanthula mwatsatanetsatane panthawi yothandiza. Zomwe zili mwatsatanetsatane ndi izi:

1. Kudula Chip

Pakuyika kwa semiconductor, kudula kwa chip kumaphatikizapo kudula zowotcha za silicon kukhala tchipisi tating'ono ndikuchotsa mwachangu zinyalala za silicon kuti zipewe zolepheretsa kugwira ntchito motsatira komanso kuwongolera khalidwe.

2. Chip Mounting

Kuyika kwa chip kumayang'ana kwambiri kupewa kuwonongeka kwa dera panthawi yopera yophika pogwiritsa ntchito filimu yoteteza, ndikugogomezera kukhulupirika kwa dera.

3. Njira Yopangira Mawaya

Kuwongolera mtundu wa njira yolumikizira mawaya kumaphatikizapo kugwiritsa ntchito mitundu yosiyanasiyana ya mawaya agolide kulumikiza zomangira za chip ndi zomangira, kuwonetsetsa kuti chip chimatha kulumikizana ndi mabwalo akunja ndikusunga umphumphu wonse. Nthawi zambiri, mawaya agolide opangidwa ndi doped ndi mawaya agolide ophatikizidwa amagwiritsidwa ntchito.

Mawaya Agolide a Doped: Mitundu imaphatikizapo GS, GW, ndi TS, yoyenera arc apamwamba (GS: > 250 μm), arc-high arc (GW: 200-300 μm), ndi arc-low-arc (TS: 100-200 μm) kugwirizana motsatana.

Mawaya Agolide Ophatikizana: Mitundu imaphatikizapo AG2 ndi AG3, yoyenera kulumikiza kwapansi (70-100 μm).

Zosankha ziwiri za mawayawa zimachokera ku 0.013 mm mpaka 0.070 mm. Kusankha mtundu woyenera ndi m'mimba mwake motengera zofunikira ndi miyezo yogwirira ntchito ndikofunikira pakuwongolera khalidwe.

4. Kuumba Njira

Zozungulira zazikulu zomwe zimapangidwira zimaphatikizanso encapsulation. Kuwongolera khalidwe la kuumba kumateteza zigawozo, makamaka kuchokera ku mphamvu zakunja zomwe zimayambitsa kuwonongeka kosiyana. Izi zimaphatikizapo kusanthula mwatsatanetsatane za zigawo za thupi.

Njira zazikulu zitatu zomwe zimagwiritsidwa ntchito pakali pano: kuyika kwa ceramic, kuyika kwa pulasitiki, ndi kuyika kwachikhalidwe. Kuwongolera gawo la mtundu uliwonse wapaketi ndikofunikira kuti zikwaniritse zofuna zapadziko lonse lapansi za kupanga chip. Panthawiyi, luso lathunthu limafunikira, monga kutenthetsa chip ndi chimango chotsogolera musanatseke ndi epoxy resin, kuumba, ndi kuchiritsa pambuyo nkhungu.

5. Njira Yochiritsa Pambuyo Pochiritsa

Pambuyo poumba, chithandizo chochiritsira pambuyo pake chimafunika, kuyang'ana pa kuchotsa zinthu zilizonse zowonjezera kuzungulira ndondomeko kapena phukusi. Kuwongolera kwabwino ndikofunikira kuti tipewe kusokoneza machitidwe onse komanso mawonekedwe.

6.Kuyesa Njira

Njira zam'mbuyomu zikamalizidwa, zonse zomwe zachitikazo ziyenera kuyesedwa pogwiritsa ntchito matekinoloje apamwamba oyesera ndi zida. Izi zikuphatikizapo kujambula mwatsatanetsatane deta, kuyang'ana ngati chip chimagwira ntchito moyenera malinga ndi momwe chimagwirira ntchito. Popeza kukwera mtengo kwa zida zoyezera, ndikofunikira kuti muzitha kuyang'anira bwino nthawi zonse zopanga, kuphatikiza kuyang'anira zowonera komanso kuyesa magwiridwe antchito amagetsi.

Kuyesa Kwamagwiridwe Amagetsi: Izi zimaphatikizapo kuyesa mabwalo ophatikizika pogwiritsa ntchito zida zoyesera zokha ndikuwonetsetsa kuti dera lililonse lalumikizidwa moyenera kuyezetsa magetsi.

Kuyang'ana Mwachiwonekere: Akatswiri amagwiritsa ntchito maikulosikopu kuti ayang'ane bwino tchipisi tapakiti zomwe zamalizidwa kuti zitsimikizire kuti zilibe cholakwika ndikukwaniritsa miyezo yapamwamba yapackage ya semiconductor.

7. Njira Yolembera

Kuyika chizindikiro kumaphatikizapo kusamutsa tchipisi toyesedwa ku nyumba yosungiramo zinthu zomalizidwa pang'ono kuti zithe kukonzedwa komaliza, kuunika bwino, kulongedza, ndi kutumiza. Njirayi ili ndi njira zitatu zazikulu:

1) Electroplating: Pambuyo popanga zitsogozo, chinthu chotsutsana ndi dzimbiri chimayikidwa kuti chiteteze makutidwe ndi okosijeni ndi dzimbiri. Tekinoloje ya electroplating deposition imakonda kugwiritsidwa ntchito popeza mitsogozo yambiri imakhala ya malata.

2) Kupindika: Zotsogola zokonzedwazo zimapangidwira, ndi mzere wozungulira wophatikizika woyikidwa mu chida chopangira kutsogolera, kuwongolera mawonekedwe otsogola (mtundu wa J kapena L) ndi ma CD okwera pamwamba.

3) Kusindikiza kwa Laser: Pomaliza, zopangidwazo zimasindikizidwa ndi mapangidwe, omwe amakhala ngati chizindikiro chapadera pamapakedwe a semiconductor, monga tawonetsera pa Chithunzi 3.

Mavuto ndi Malangizo

Kuphunzira kwa ma semiconductor ma CD ma phukusi kumayamba ndikuwunika mwachidule ukadaulo wa semiconductor kuti mumvetsetse mfundo zake. Chotsatira, kuyang'ana kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kamwemwemwe kapabudwenke kapanganikambo WAANI WAANI ukubonakalalelolelo ukubonakalajoro koku59taba9 koku55 iliyokobana ukulizwe ndi kachitidwe kachitidwe kazinthu zitheke, kugwiritsa ntchito kasamalidwe koyengedwa bwino kuti tipewe zovuta zanthawi zonse. Pankhani yachitukuko chamakono, kuzindikira zovuta mumayendedwe a semiconductor phukusi ndikofunikira. Ndi bwino kuganizira mbali khalidwe kulamulira, bwinobwino bwino mfundo zazikulu kuti mogwira kumapangitsanso ndondomeko khalidwe.

Kuwunika kuchokera ku kayendetsedwe ka kayendetsedwe kabwino, pali zovuta zazikulu panthawi yogwiritsira ntchito chifukwa cha njira zambiri zomwe zili ndi zofunikira zenizeni ndi zofunikira, zomwe zimakhudza wina. Kuwongolera mwamphamvu kumafunika panthawi yantchito. Pokhala ndi mtima wosamala pogwira ntchito ndi kugwiritsa ntchito umisiri wapamwamba kwambiri, njira yolongedza semiconductor ndi luso laukadaulo zitha kuwongoleredwa, kuwonetsetsa kuti ntchitoyo ikugwira ntchito bwino ndikupindula bwino kwambiri. (monga momwe tawonetsera pa Chithunzi 3).

Nthawi yotumiza: May-22-2024