Magawo a Silicon carbide (SiC) ali ndi zolakwika zambiri zomwe zimalepheretsa kukonza mwachindunji. Kuti apange ma chip wafers, filimu yeniyeni ya kristalo iyenera kukulitsidwa pagawo la SiC kudzera mu njira ya epitaxial. Filimuyi imadziwika kuti epitaxial layer. Pafupifupi zida zonse za SiC zimazindikirika pazinthu za epitaxial, ndipo zida zapamwamba za homoepitaxial SiC zimapanga maziko opangira zida za SiC. Kuchita kwa zida za epitaxial kumatsimikizira mwachindunji magwiridwe antchito a zida za SiC.

Zipangizo zamakono za SiC zamakono komanso zodalirika kwambiri zimayika zofunikira pamapangidwe apamwamba, kachulukidwe kachilema, kufanana kwa doping, ndi kufanana kwa makulidwe aepitaxialzipangizo. Kukwaniritsa kukula kwakukulu, kachulukidwe kakang'ono, ndi mawonekedwe apamwamba a SiC epitaxy kwakhala kofunika kwambiri pa chitukuko cha makampani a SiC.

Kupanga epitaxy yapamwamba kwambiri ya SiC kumadalira njira zapamwamba ndi zida. Pakalipano, njira yomwe imagwiritsidwa ntchito kwambiri pakukula kwa SiC epitaxial ndiChemical Vapor Deposition (CVD).CVD imapereka chiwongolero cholondola pa makulidwe a filimu ya epitaxial ndi ndende ya doping, kachulukidwe kakang'ono kachilema, kukula pang'onopang'ono, ndi kuwongolera makina, ndikupangitsa kuti ikhale ukadaulo wodalirika wogwiritsa ntchito bwino malonda.

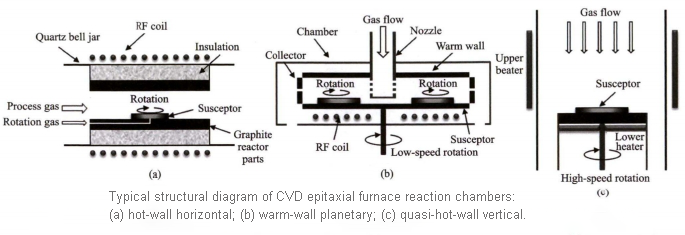

SiC CVD epitaxynthawi zambiri amagwiritsa ntchito zida za CVD zotentha kapena zotentha. Kutentha kwakukulu kwa kukula (1500-1700 ° C) kumatsimikizira kupitiriza kwa mawonekedwe a crystalline 4H-SiC. Kutengera ubale womwe ulipo pakati pa njira yoyendetsera gasi ndi gawo lapansi, zipinda zomwe zimapangidwira machitidwe a CVD zitha kugawidwa m'magulu opingasa komanso ofukula.

Ubwino wa ng'anjo za SiC epitaxial zimayesedwa makamaka pazigawo zitatu: kukula kwa epitaxial (kuphatikiza kufanana kwa makulidwe, kufanana kwa doping, chilema, ndi kukula kwake), kutentha kwa zipangizo (kuphatikizapo kutentha / kuzizira, kutentha kwakukulu, ndi kutentha mofanana. ), komanso kutsika mtengo (kuphatikiza mtengo wagawo ndi mphamvu zopanga).

Kusiyana Pakati pa Mitundu Itatu ya SiC Epitaxial Growth Furnaces

1.Hot-wall Horizontal CVD Systems:

-Mawonekedwe:Nthawi zambiri imakhala ndi makina okulirapo amtundu umodzi wowongoka woyendetsedwa ndi kuyandama kwa gasi, kukwaniritsa ma metrics abwino kwambiri a intra-wafer.

-Chitsanzo choyimira:LPE's Pe1O6, yomwe imatha kutsitsa / kutsitsa pa 900 ° C. Amadziwika ndi kukula kwakukulu, ma epitaxial cycle afupikitsa, komanso magwiridwe antchito osasinthika a intra-wafer ndi inter-run performance.

-Kachitidwe:Kwa 4-6 inchi 4H-SiC epitaxial wafers ndi makulidwe ≤30μm, imakwaniritsa makulidwe a intra-wafer osafanana ≤2%, ndende ya doping yosafanana ≤5%, kachulukidwe pachilema ≤1 cm-², komanso yopanda chilema. pamwamba (2mm × 2mm maselo) ≥90%.

-Opanga Pakhomo: Makampani monga Jingsheng Mechatronics, CETC 48, North Huachuang, ndi Nasset Intelligent apanga zida zofananira za SiC epitaxial za single-wafer zomwe zimakhala ndi ma scaled-up.

2.Warm-wall Planetary CVD Systems:

-Mawonekedwe:Gwiritsani ntchito maziko a mapulaneti pakukula kwamitundu ingapo pa batch, kuwongolera bwino zotulutsa.

-Zoyimira Zoyimira:Aixtron's AIXG5WWC (8x150mm) ndi G10-SiC (9x150mm kapena 6x200mm) mndandanda.

-Kachitidwe:Kwa 6-inch 4H-SiC epitaxial wafers ndi makulidwe ≤10μm, imakwaniritsa kupatuka kwa makulidwe apakati-wafer ± 2.5%, intra-wafer makulidwe osafanana 2%, kupatuka kwa inter-wafer doping ndende ± 5%, ndi intra-wafer doping. ndende non-uniformity <2%.

-Zovuta:Kutengera pang'ono m'misika yam'nyumba chifukwa chosowa deta yopanga ma batch, zotchinga zaukadaulo pakuwongolera kutentha ndikuyenda m'munda, komanso R&D yopitilira popanda kukhazikitsa kwakukulu.

3. Quasi-hot-wall Vertical CVD Systems:

- Mawonekedwe:Gwiritsani ntchito mawotchi akunja othandizira kusinthasintha kwapang'onopang'ono, kuchepetsa makulidwe a malire ndikuwongolera kukula kwa epitaxial, ndi zabwino zake pakuwongolera zolakwika.

- Zitsanzo zoimira:Nuflare's single-wafer EPIREVOS6 ndi EPIREVOS8.

-Kachitidwe:Imakwanitsa kukula kupitirira 50μm/h, kachulukidwe kachulukidwe pamwamba pa 0.1 cm-², ndi makulidwe a intra-wafer ndi ndende ya doping yosagwirizana ndi 1% ndi 2.6%, motsatana.

-Chitukuko Pakhomo:Makampani monga Xingsandai ndi Jingsheng Mechatronics apanga zida zofananira koma sanagwiritse ntchito mokulira.

Chidule

Iliyonse mwamitundu itatu ya zida zokulirapo za SiC epitaxial ili ndi mawonekedwe ake ndipo imakhala ndi magawo ena amsika kutengera zomwe akufuna. Hot-wall horizontal CVD imapereka chiwongola dzanja chofulumira kwambiri komanso mawonekedwe abwino komanso ofanana koma imakhala ndi magwiridwe antchito otsika chifukwa cha kachipangizo kakang'ono kamodzi. CVD yotentha ya pulaneti ya CVD imathandizira kwambiri kupanga koma imayang'anizana ndi zovuta pakuwongolera kusasinthika kwamitundu yambiri. Quasi-hot-wall vertical CVD imapambana pakuwongolera zolakwika ndi mawonekedwe ovuta ndipo imafuna kukonzanso kwakukulu ndi luso la magwiridwe antchito.

Pamene makampaniwa akupita patsogolo, kukhathamiritsa kobwerezabwereza ndi kukweza kwa zida izi kumabweretsa kusinthika kochulukira, kuchita mbali zofunika kwambiri pokwaniritsa zofunikira za epitaxial wafer za makulidwe ndi zofunikira.

Ubwino ndi Kuipa kwa Zosiyanasiyana za SiC Epitaxial Growth Furnaces

| Mtundu wa Ng'anjo | Ubwino wake | Zoipa | Oimira Opanga |

| Hot-wall Horizontal CVD | Kukula kwachangu, kapangidwe kosavuta, kukonza kosavuta | Kukonzekera kwakanthawi kochepa | LPE (Italy), TEL (Japan) |

| Warm-wall Planetary CVD | Kuthekera kwakukulu kopanga, kothandiza | Kapangidwe kazovuta, kuwongolera kosasinthasintha | Aixtron (Germany) |

| Quasi-hot-wall Vertical CVD | Kuwongolera kwabwino kwambiri, kuwongolera kwanthawi yayitali | Mapangidwe ovuta, ovuta kuwasamalira | Nuflare (Japan) |

Ndi chitukuko chosalekeza chamakampani, zida zamitundu itatu iyi zidzakonzedwanso ndikukonzedwanso, zomwe zimapangitsa kuti masinthidwe ochulukirachuluke omwe amafanana ndi ma epitaxial wafer osiyanasiyana amakulidwe ndi zofunikira.

Nthawi yotumiza: Jul-19-2024