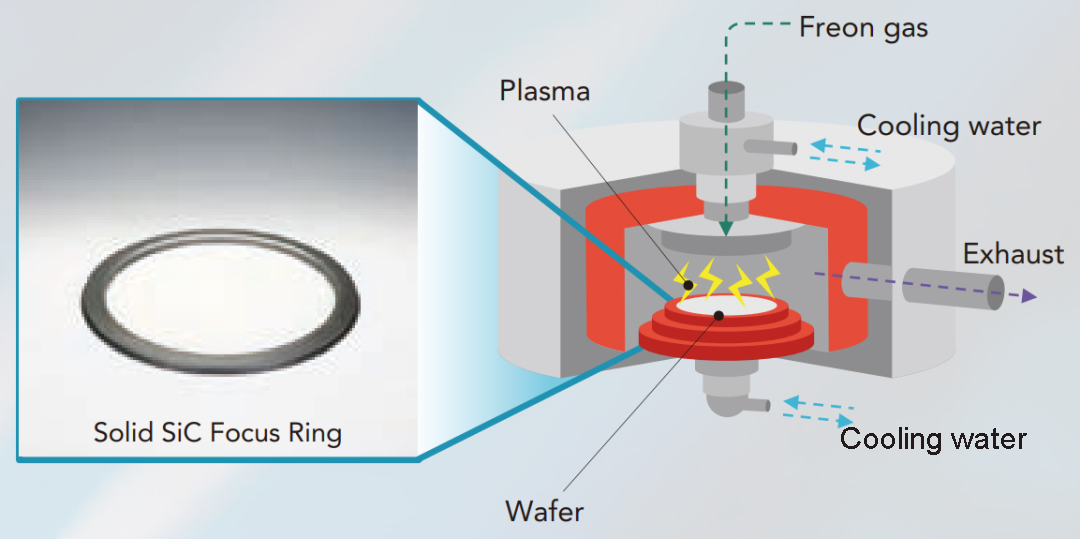

Mu zida za plasma etching, zida za ceramic zimagwira ntchito yofunikira, kuphatikizamphete yoyang'ana.The mphete yoyang'ana, yoyikidwa mozungulira chophatikiziracho ndikulumikizana nayo mwachindunji, ndiyofunikira kuti plasma ikhale pamtengowo pogwiritsira ntchito magetsi ku mphete. Izi zimakulitsa kufanana kwa njira yopangira etching.

Kugwiritsa ntchito mphete za SiC Focus mu Etching Machines

Zigawo za SiC CVDmu makina etching, mongamphete zoyang'ana, zosamba gasi, ma platens, ndi mphete za m'mphepete, zimayamikiridwa chifukwa cha kuchepa kwa SiC ndi chlorine ndi fluorine-based etching gases ndi ma conductivity ake, zomwe zimapangitsa kukhala chinthu choyenera pazida za plasma etching.

Ubwino wa SiC ngati Chida Choyang'ana mphete

Chifukwa chowonekera mwachindunji ku plasma m'chipinda cha vacuum reaction, mphete zoyang'ana ziyenera kupangidwa kuchokera kuzinthu zolimbana ndi plasma. Mphete zachikale, zopangidwa kuchokera ku silicon kapena quartz, zimakhala ndi vuto losasunthika bwino m'madzi a m'magazi opangidwa ndi fluorine, zomwe zimapangitsa kuti dzimbiri ziwonongeke komanso kuchepa kwachangu.

Kuyerekeza Pakati pa Si ndi CVD SiC Focus Rings:

1. Kuchulukana Kwambiri:Amachepetsa etching volume.

2. Wide Bandgap: Amapereka insulation yabwino kwambiri.

3. High Thermal Conductivity & Low Extutional Coefficient: Kugonjetsedwa ndi kutentha kwa kutentha.

4. Kuthamanga Kwambiri:Kukaniza kwabwino pamakina amakina.

5. Kulimba Kwambiri: Zovala ndi zosagwira dzimbiri.

SiC imagawana mphamvu zamagetsi za silicon pomwe ikupereka kukana kwa ionic etching. Pamene integrated circuit miniaturization ikupita patsogolo, kufunikira kwa njira zowongolera bwino kumawonjezeka. Zida zojambulira plasma, makamaka zomwe zimagwiritsa ntchito capacitive coupled plasma (CCP), zimafuna mphamvu zambiri za plasma, kupangaSiC focus mphetekutchuka kwambiri.

Si ndi CVD SiC Focus Ring Parameters:

| Parameter | Silicon (Si) | CVD Silicon Carbide (SiC) |

| Kachulukidwe (g/cm³) | 2.33 | 3.21 |

| Band Gap (eV) | 1.12 | 2.3 |

| Thermal Conductivity (W/cm°C) | 1.5 | 5 |

| Kuwonjeza Koyelekeza kwa Kutentha (x10⁻⁶/°C) | 2.6 | 4 |

| Elastic Modulus (GPA) | 150 | 440 |

| Kuuma | Pansi | Zapamwamba |

Njira Yopanga ya SiC Focus Rings

Mu zida za semiconductor, CVD (Chemical Vapor Deposition) imagwiritsidwa ntchito popanga zida za SiC. Mphete za Focus zimapangidwa poyika SiC m'mawonekedwe enaake kudzera pakuyika kwa nthunzi, kutsatiridwa ndi kukonza kwamakina kuti apange chomaliza. Chiyerekezo cha zinthu pakuyika kwa nthunzi chimakhazikika pambuyo poyeserera mozama, kupangitsa magawo ngati resistivity kusasinthasintha. Komabe, zida zosiyanasiyana zama etching zitha kufunikira mphete zowunikira zokhala ndi zopinga zosiyanasiyana, zomwe zimafunikira kuyesa kwazinthu zatsopano pamatchulidwe aliwonse, omwe amatenga nthawi komanso okwera mtengo.

Mwa kusankhaSiC focus mphetekuchokeraSemicera Semiconductor, makasitomala amatha kupindula ndi maulendo aatali osinthika ndikuchita bwino popanda kuwonjezeka kwakukulu kwa mtengo.

Zigawo za Rapid Thermal Processing (RTP).

Kutentha kwapadera kwa CVD SiC kumapangitsa kuti ikhale yabwino pamapulogalamu a RTP. Zigawo za RTP, kuphatikiza mphete zam'mphepete ndi mapepala, zimapindula ndi CVD SiC. Panthawi ya RTP, kutentha kwamphamvu kumagwiritsidwa ntchito pa zowotcha zapayekha kwakanthawi kochepa, ndikutsatiridwa ndi kuzizira kofulumira. CVD SiC m'mphepete mphete, kukhala woonda ndi otsika matenthedwe misa, musati kusunga kutentha kwambiri, kuwapangitsa kukhala osakhudzidwa ndi Kutentha mofulumira ndi kuzirala njira.

Zigawo za Plasma Etching

CVD SiC's high chemical resistance imapangitsa kuti ikhale yoyenera kugwiritsa ntchito etching. Zipinda zambiri zotsekera zimagwiritsa ntchito mbale zogawa gasi za CVD SiC kugawira mpweya wokhazikika, wokhala ndi mabowo ang'onoang'ono masauzande akumwaza kwa plasma. Poyerekeza ndi zipangizo zina, CVD SiC ili ndi reactivity yochepa ndi chlorine ndi mpweya wa fluorine. Mu etching youma, zida za CVD SiC monga mphete zoyang'ana, ma ICP platen, mphete zamalire, ndi shawawa zimagwiritsidwa ntchito.

Mphete zoyang'ana za SiC, zomwe zimagwiritsidwa ntchito poyang'ana plasma, ziyenera kukhala ndi ma conductivity okwanira. Nthawi zambiri amapangidwa ndi silicon, mphete zowunikira zimakumana ndi mpweya wokhazikika wokhala ndi fluorine ndi klorini, zomwe zimatsogolera ku dzimbiri kosapeŵeka. Mphete zoyang'ana za SiC, zokhala ndi kukana kwambiri kwa dzimbiri, zimapereka moyo wautali poyerekeza ndi mphete za silicon.

Kufananiza kwa Moyo Wonse:

Mphete za SiC Focus:Amasinthidwa masiku 15 mpaka 20 aliwonse.

· Mphete za Silicon Focus:Amasinthidwa masiku 10 mpaka 12 aliwonse.

Ngakhale mphete za SiC zimakhala zokwera mtengo 2 mpaka 3 kuposa mphete za silicon, nthawi yayitali yosinthira imachepetsa mtengo wazinthu zonse, popeza mavalidwe onse mchipindacho amasinthidwa nthawi imodzi pomwe chipinda chimatsegulidwa kuti chilowetsenso mphete.

Mphete za Semicera Semiconductor za SiC Focus

Semicera Semiconductor imapereka mphete zoyang'ana za SiC pamitengo yoyandikira ya mphete za silicon, ndi nthawi yotsogolera ya masiku pafupifupi 30. Pophatikiza mphete za Semicera's SiC mu zida zojambulira plasma, magwiridwe antchito ndi moyo wautali zimawongoleredwa bwino, kuchepetsa ndalama zonse zokonzekera ndikukweza kupanga bwino. Kuphatikiza apo, Semicera imatha kusintha makonda a mphete zowunikira kuti akwaniritse zofunikira zamakasitomala.

Posankha mphete zoyang'ana za SiC kuchokera ku Semicera Semiconductor, makasitomala atha kupeza phindu lakusintha kwanthawi yayitali komanso magwiridwe antchito apamwamba popanda kukwera mtengo kwamitengo.

Nthawi yotumiza: Jul-10-2024