Mpweya ndi chimodzi mwazinthu zomwe zimapezeka kwambiri m'chilengedwe, zomwe zimaphatikizapo pafupifupi zinthu zonse zomwe zimapezeka padziko lapansi. Imawonetsa mawonekedwe osiyanasiyana, monga kuuma kosiyanasiyana ndi kufewa, kutsekereza-semiconductor-superconductor khalidwe, kutentha kwa kutentha-superconductivity, ndi kuyamwa kwa kuwala-kuwonetsetsa kwathunthu. Mwa izi, zida zomwe zili ndi sp2 hybridization ndi mamembala akuluakulu a banja la zida za kaboni, kuphatikiza ma graphite, ma carbon nanotubes, graphene, fullerenes, ndi amorphous glassy carbon.

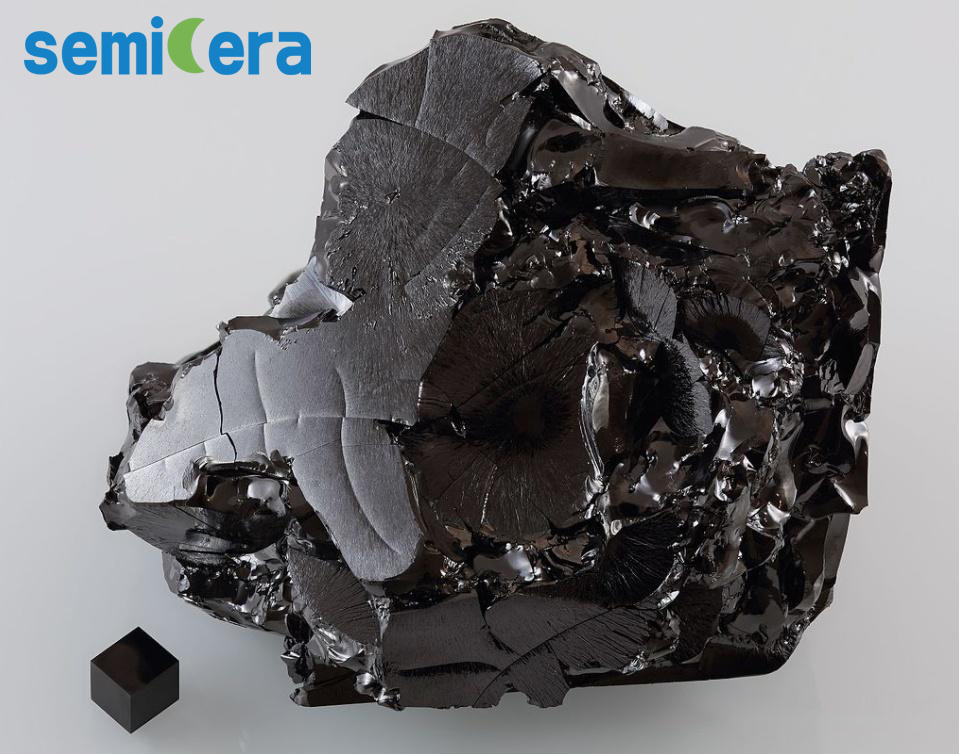

Zitsanzo za Carbon ya Graphite ndi Galasi

Ngakhale zida zam'mbuyo ndizodziwika bwino, tiyeni tiyang'ane pa kaboni wagalasi lero. Mpweya wagalasi, womwe umadziwikanso kuti kaboni wagalasi kapena vitreous carbon, umaphatikiza zinthu zamagalasi ndi zoumba kukhala zinthu za kaboni zomwe sizili ndi graphitic. Mosiyana ndi crystalline graphite, ndi amorphous carbon material yomwe ili pafupifupi 100% sp2-hybridized. Mpweya wagalasi umapangidwa ndi kutentha kwambiri kwa zinthu zopangira zinthu, monga phenolic resins kapena furfuryl alcohol resins, pansi pa mpweya wa mpweya. Maonekedwe ake akuda komanso mawonekedwe osalala ngati galasi adapatsa dzina loti "carbon carbon".

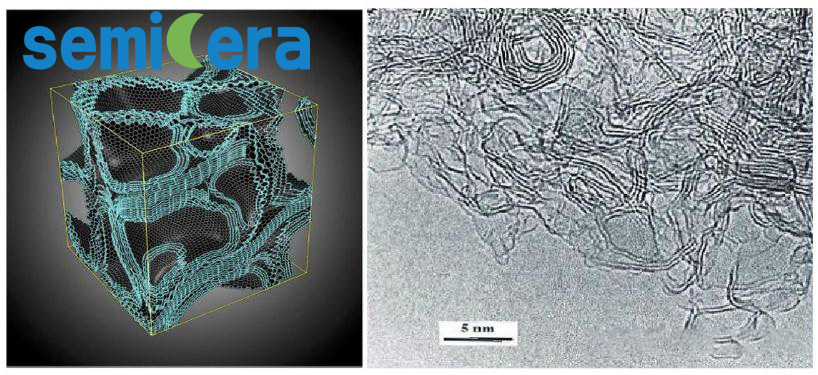

Chiyambireni kaphatikizidwe kake koyamba ndi asayansi mu 1962, kapangidwe ndi kapangidwe ka kaboni wagalasi zaphunziridwa mozama ndikukhalabe mutu wovuta kwambiri pankhani ya zida za kaboni. Mpweya wagalasi ukhoza kugawidwa m'magulu awiri: Type I ndi Type II carbony carbon. Mpweya wagalasi wa Type I umapangidwa kuchokera ku zinthu zoyambira organic pa kutentha kosachepera 2000 ° C ndipo umakhala makamaka ndi zidutswa za graphene zopindika mwachisawawa. Komano, kaboni wagalasi wa Type II, umatenthedwa pakatentha kwambiri (~ 2500°C) ndipo umapanga matrix aamorphous multilayered atatu-dimensional of self-asembled fullerene-like spherical structures (monga momwe tawonera m'chithunzichi).

Chifaniziro cha Kaboni wa Galasi (Kumanzere) ndi Chithunzi cha Electron Microscopy chapamwamba (Kumanja)

Kafukufuku waposachedwa wapeza kuti mtundu wa 2 wagalasi wa kaboni umawonetsa kupsinjika kwambiri kuposa Mtundu Woyamba, womwe umadziwika ndi mawonekedwe ake ozungulira omwe amadziphatikiza okha ngati a fullerene. Ngakhale pali kusiyana pang'ono kwa geometric, onse a Type I ndi Type II matricy carbon matrices amapangidwa ndi graphene yopindika.

Kugwiritsa ntchito Glassy Carbon

Mpweya wagalasi wagalasi uli ndi zinthu zambiri zabwino, kuphatikizapo kutsika kochepa, kuuma kwakukulu, mphamvu zambiri, kusasunthika kwa mpweya ndi zakumwa, kutentha kwakukulu ndi kukhazikika kwa mankhwala, zomwe zimapangitsa kuti zigwiritsidwe ntchito m'mafakitale monga kupanga, chemistry, ndi zamagetsi.

01 Mapulogalamu Otentha Kwambiri

Mpweya wagalasi umawonetsa kukana kutentha kwambiri m'malo opanda mpweya kapena mpweya, kupirira kutentha mpaka 3000 ° C. Mosiyana ndi zida zina za ceramic ndi zitsulo zotentha kwambiri, mphamvu ya kaboni wagalasi imawonjezeka ndi kutentha ndipo imatha kufika pa 2700K popanda kukhala brittle. Ilinso ndi misa yocheperako, mayamwidwe a kutentha pang'ono, komanso kufutukuka kwamafuta pang'ono, kupangitsa kuti ikhale yoyenera kugwiritsa ntchito zosiyanasiyana zotentha kwambiri, kuphatikiza machubu oteteza thermocouple, makina otsegulira, ndi zida za ng'anjo.

02 Chemical Applications

Chifukwa cha kukana kwake kwa dzimbiri, kaboni wagalasi umagwiritsidwa ntchito kwambiri pakuwunika mankhwala. Zipangizo zopangidwa ndi kaboni wagalasi zimapereka zabwino kuposa zida wamba za labotale zopangidwa kuchokera ku platinamu, golide, zitsulo zina zosagwira dzimbiri, zoumba zapadera, kapena fluoroplastics. Ubwinowu umaphatikizapo kukana zinthu zonse zowola zonyowa, osakumbukira (kutsatsa kosalamulirika ndi kutayika kwa zinthu), kusayipitsidwa kwa zitsanzo zowunikidwa, kukana ma acid ndi kusungunuka kwa alkaline, komanso magalasi osakhala ndi porous.

03 Dental Technology

Magalasi a carbon crucibles amagwiritsidwa ntchito kwambiri muukadaulo wamano kusungunula zitsulo zamtengo wapatali ndi ma aloyi a titaniyamu. Amapereka maubwino monga matenthedwe apamwamba, kutalika kwa moyo poyerekeza ndi ma graphite crucibles, osamata zitsulo zamtengo wapatali zosungunuka, kukana kugwedezeka kwamafuta, kugwiritsa ntchito zitsulo zonse zamtengo wapatali ndi ma aloyi a titaniyamu, kugwiritsa ntchito ma induction casting centrifuges, kupanga mlengalenga woteteza pazitsulo zosungunuka, ndi kuthetsa kufunikira kwa kusinthasintha.

Kugwiritsiridwa ntchito kwa magalasi a carbon crucibles kumachepetsa kutentha ndi nthawi yosungunuka ndipo kumapangitsa kuti zowotchera zazitsulo zosungunula zizigwira ntchito potentha kwambiri kusiyana ndi zotengera zadothi zadothi, motero kuchepetsa nthawi yofunikira pakuponyedwa kulikonse ndikutalikitsa moyo wa crucible. Komanso, kusanyowa kwake kumathetsa nkhawa za kutaya zinthu.

04 Mapulogalamu a Semiconductor

Mpweya wagalasi, wokhala ndi kuyera kwakukulu, kukana kwa dzimbiri kwapadera, kusakhalapo kwa tinthu tating'onoting'ono, ma conductivity, komanso makina abwino amakina, ndi chinthu choyenera kupanga semiconductor. Ma Crucibles ndi mabwato opangidwa kuchokera ku magalasi a carbon angagwiritsidwe ntchito kusungunuka kwa zigawo za semiconductor pogwiritsa ntchito njira za Bridgman kapena Czochralski, kaphatikizidwe ka gallium arsenide, ndi kukula kwa crystal imodzi. Kuphatikiza apo, kaboni wagalasi utha kukhala ngati zigawo za ma ion implantation system ndi ma elekitirodi mumayendedwe a plasma etching. Kuwonekera kwake kwakukulu kwa X-ray kumapangitsanso magalasi a carbon tchipisi kukhala oyenera ma X-ray mask substrates.

Pomaliza, kaboni wagalasi umapereka zinthu zapadera zomwe zimaphatikizapo kukana kutentha kwambiri, kusakhazikika kwamankhwala, komanso magwiridwe antchito amakina, ndikupangitsa kuti ikhale yoyenera kugwiritsidwa ntchito mosiyanasiyana m'mafakitale osiyanasiyana.

Lumikizanani ndi Semicera kuti mupeze zinthu zamagalasi a carbon.

Imelo:sales05@semi-cera.com

Nthawi yotumiza: Dec-18-2023