Zipangizo zamagetsi za semiconductor zimakhala ndi malo ofunikira kwambiri pamagetsi amagetsi amagetsi, makamaka pokhudzana ndi chitukuko chofulumira cha matekinoloje monga luntha lochita kupanga, mauthenga a 5G ndi magalimoto atsopano amphamvu, zofunikira zogwirira ntchito kwa iwo zasinthidwa.

Silicon carbide(4H-SiC) wakhala mfundo yabwino kwa kupanga mkulu-ntchito semiconductor mphamvu zipangizo chifukwa cha ubwino wake monga bandgap lonse, mkulu matenthedwe madutsidwe, mkulu kuwonongeka kumunda mphamvu, mkulu machulukitsidwe kutengeka mlingo, bata mankhwala ndi kukana poizoniyu. Komabe, 4H-SiC ili ndi kuuma kwakukulu, brittleness yapamwamba, inertness yamphamvu yamankhwala, komanso kuvutikira kwakukulu. Kapangidwe kake kagawo kakang'ono kagawo kakang'ono kake ndi kofunikira pakugwiritsa ntchito zida zazikulu.

Chifukwa chake, kuwongolera mawonekedwe amtundu wa 4H-SiC gawo lapansi, makamaka kuchotsa wosanjikiza wowonongeka pamtunda wowongolera, ndiye chinsinsi chothandizira kukonza bwino, kutayika kochepa komanso apamwamba kwambiri a 4H-SiC gawo lapansi lawafa.

Yesani

Kuyeseraku kumagwiritsa ntchito 4-inch N-mtundu wa 4H-SiC ingot yomwe imakula ndi njira yoyendetsera nthunzi, yomwe imakonzedwa kudzera mu kudula waya, kugaya, kugaya movutikira, kupera bwino ndi kupukuta, ndikulemba makulidwe ochotsa pamwamba pa C ndi Si pamwamba. ndi makulidwe omaliza a mkate munjira iliyonse.

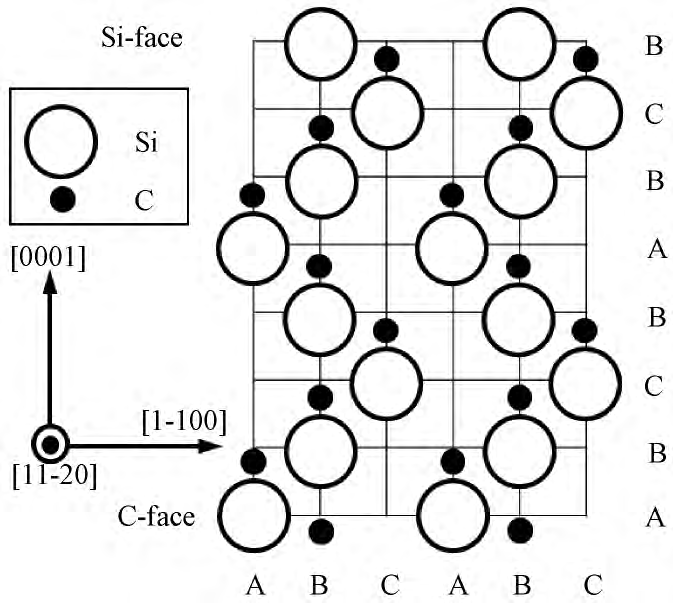

Chithunzi cha 1 Schematic chojambula cha 4H-SiC kapangidwe ka kristalo

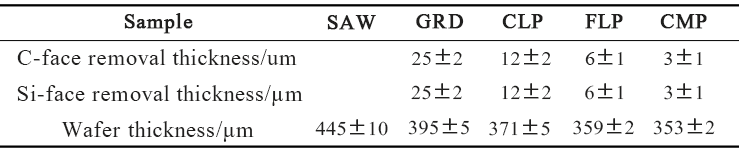

Chithunzi 2 Makulidwe achotsedwa ku C-side ndi Si-mbali ya 4H-SiC chowotchapambuyo masitepe osiyana processing ndi makulidwe a mtanda pambuyo processing

The makulidwe, pamwamba morphology, roughness ndi katundu makina yopyapyala anali bwino yodziwika ndi yopyapyala geometry parameter tester, kusiyana kusokoneza maikulosikopu, atomiki mphamvu ya microscope, pamwamba roughness kuyeza chida ndi nanoindenter. Kuphatikiza apo, X-ray diffractometer yokhala ndi mawonekedwe apamwamba idagwiritsidwa ntchito kuyesa mtundu wa kristalo wa chophatikiziracho.

Njira zoyesera izi ndi njira zoyesera zimapereka chithandizo chatsatanetsatane chaukadaulo powerenga kuchuluka kwa zinthu zochotsa komanso kutsika kwapamtunda panthawi yokonza 4H-Zophika za SiC.

Kupyolera muzoyesera, ofufuzawo adasanthula kusintha kwa kuchuluka kwa kuchotsedwa kwa zinthu (MRR), mawonekedwe apamwamba komanso kuuma, komanso mawonekedwe amakina ndi mtundu wa crystal wa 4H-Zophika za SiCm'njira zosiyanasiyana zopangira (kudula waya, kugaya, kugaya movutikira, kugaya bwino, kupukuta).

Chithunzi 3 Kuchotsa kwa zinthu za C-nkhope ndi Si-nkhope ya 4H-SiC chowotcham'njira zosiyanasiyana processing

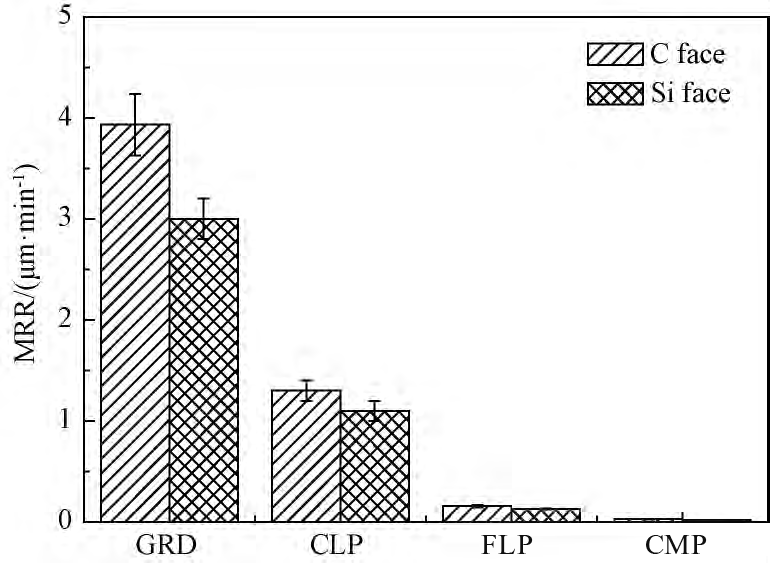

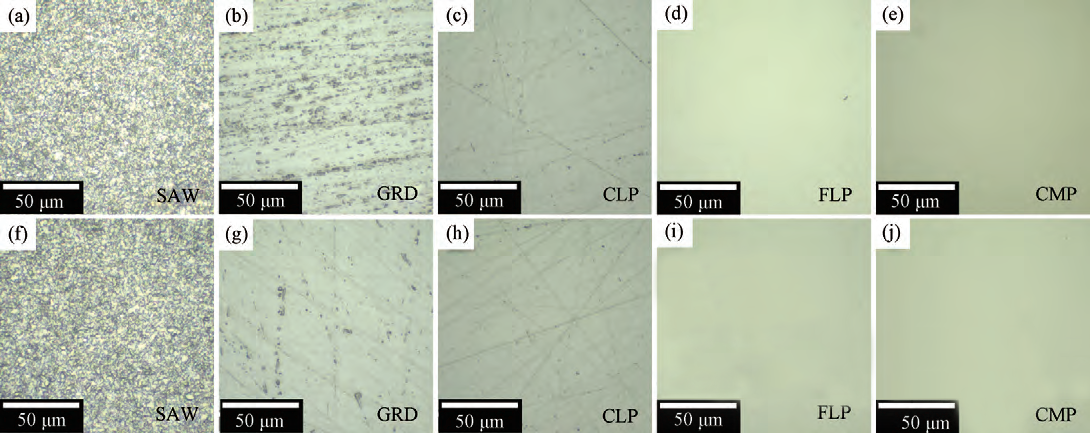

Kafukufukuyu adapeza kuti chifukwa cha anisotropy yamakina amitundu yosiyanasiyana ya 4H-SiC, pali kusiyana kwa MRR pakati pa C-nkhope ndi Si-nkhope panjira yomweyo, ndipo MRR wa C-nkhope ndi wapamwamba kwambiri kuposa wa Si-face. Ndi kupita patsogolo kwa masitepe opangira, mawonekedwe a pamwamba ndi roughness ya 4H-SiC wafers amakonzedwa pang'onopang'ono. Pambuyo popukuta, Ra wa C-nkhope ndi 0.24nm, ndipo Ra wa Si-nkhope amafika 0.14nm, yomwe ingakwaniritse zosowa za kukula kwa epitaxial.

Chithunzi cha 4 Zithunzi za microscope zowoneka bwino za C pamwamba (a~e) ndi Si pamwamba (f~j) za 4H-SiC wafer pambuyo pokonza njira zosiyanasiyana.

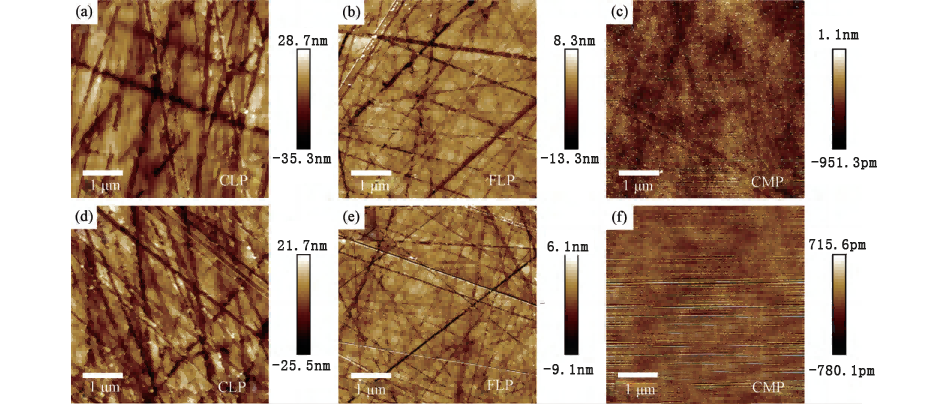

Chithunzi 5 Zithunzi za microscope ya Atomiki ya C pamwamba (a~c) ndi Si pamwamba (d~f) ya 4H-SiC wafer pambuyo pa njira za CLP, FLP ndi CMP

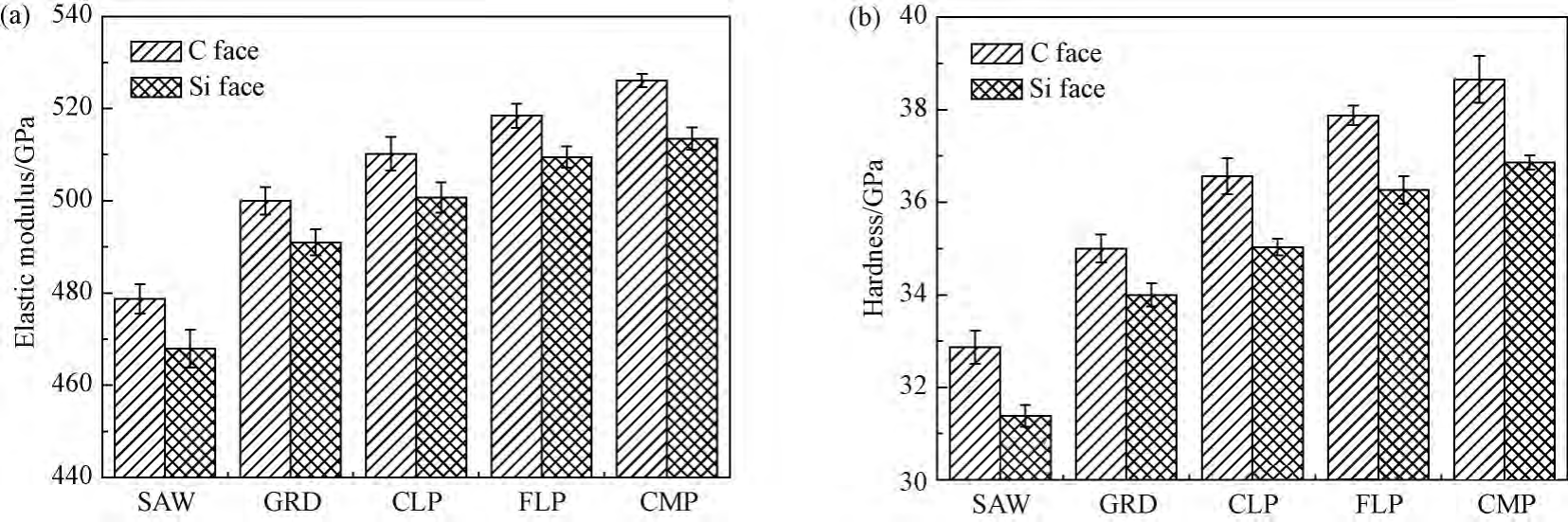

Chithunzi 6 (a) zotanuka modulus ndi (b) kuuma kwa C pamwamba ndi Si pamwamba pa 4H-SiC yopyapyala pambuyo njira zosiyanasiyana processing

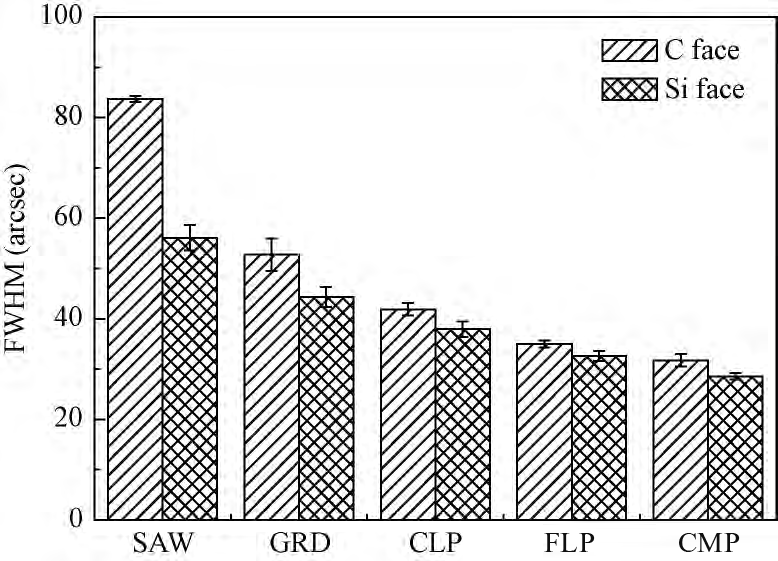

Kuyesa kwazinthu zamakina kumawonetsa kuti C pamwamba pa chowotchacho imakhala yolimba kwambiri kuposa ya Si pamwamba, kusweka kwakukulu pakukonza, kuchotsa zinthu mwachangu, komanso kusakhala bwino kwapamtunda komanso kuwuma. Kuchotsa wosanjikiza wowonongeka pa malo okonzedwa ndiye chinsinsi chowongolera mawonekedwe a pamwamba pa mtanda. Theka la kutalika kwa 4H-SiC (0004) yokhotakhota yokhotakhota ingagwiritsidwe ntchito mwachidziwitso komanso molondola kuwonetsa ndikuwunika kuwonongeka kwapang'onopang'ono.

Chithunzi 7 (0004) yokhotakhota m'lifupi mwake m'lifupi la C-nkhope ndi Si-nkhope ya 4H-SiC wafer pambuyo pokonza njira zosiyanasiyana.

Zotsatira zafukufuku zikuwonetsa kuti gawo lowonongeka la chophimbacho limatha kuchotsedwa pang'onopang'ono pambuyo pa 4H-SiC wafer processing, yomwe imathandizira bwino mawonekedwe a pamwamba pa mtandawo ndipo imapereka chidziwitso chaukadaulo chakuchita bwino kwambiri, kutayika kochepa komanso kukonza kwapamwamba. za 4H-SiC gawo lapansi lophika.

Ofufuzawa adakonza zowotcha za 4H-SiC kudzera munjira zosiyanasiyana zopangira monga kudula waya, kugaya, kugaya movutikira, kupukuta bwino komanso kupukuta, ndikuwunikanso zotsatira za njirazi pamtundu wapamtunda.

Zotsatira zikuwonetsa kuti ndikupita patsogolo kwa masitepe opangira, mawonekedwe a pamwamba ndi roughness of the wafer amakonzedwa pang'onopang'ono. Pambuyo kupukuta, roughness ya C-nkhope ndi Si-nkhope kufika 0.24nm ndi 0.14nm motero, amene amakwaniritsa zofunika kukula epitaxial. Nkhope ya C ya chophatikizira imakhala yolimba kwambiri kuposa ya Si-face, ndipo imakonda kusweka pang'onopang'ono ikakonzedwa, zomwe zimapangitsa kuti pakhale morphology yoyipa komanso roughness. Kuchotsa pamwamba kuwonongeka wosanjikiza wa kukonzedwa pamwamba ndi chinsinsi kuwongolera pamwamba khalidwe la yopyapyala. Theka-m'lifupi mwake mwa 4H-SiC (0004) wokhotakhota amatha kuwonetsa mwachidwi komanso molondola mawonekedwe owonongeka a pamwamba pa mtandawo.

Kafukufuku akuwonetsa kuti wosanjikiza wowonongeka pamwamba pa zowotcha za 4H-SiC zitha kuchotsedwa pang'onopang'ono kudzera mu 4H-SiC wafer processing, kuwongolera bwino pamwamba pa chophatikiziracho, ndikupereka chidziwitso chaukadaulo chakuchita bwino kwambiri, kutayika kochepa, komanso kukonza kwamtundu wa 4H-SiC gawo lapansi lophika.

Nthawi yotumiza: Jul-08-2024