Dry etching process nthawi zambiri imakhala ndi zigawo zinayi zofunika: isanayambe kukokera, etching pang'ono, etching, ndi etching. Makhalidwe akuluakulu ndi etching rate, selectivity, dimensional dimension, kufanana, ndi kuzindikira mapeto.

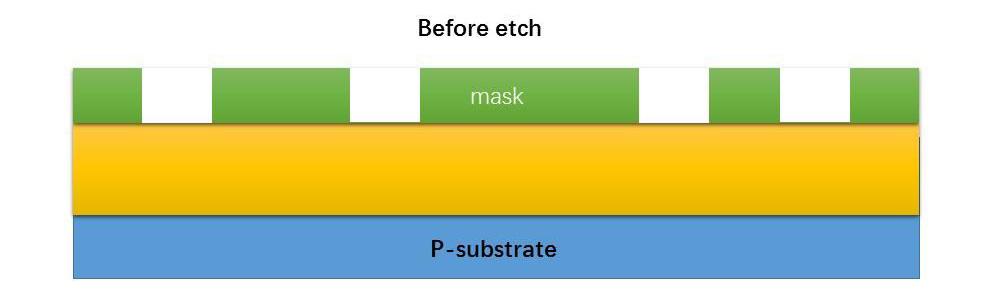

Chithunzi 1 Musanayambe etching

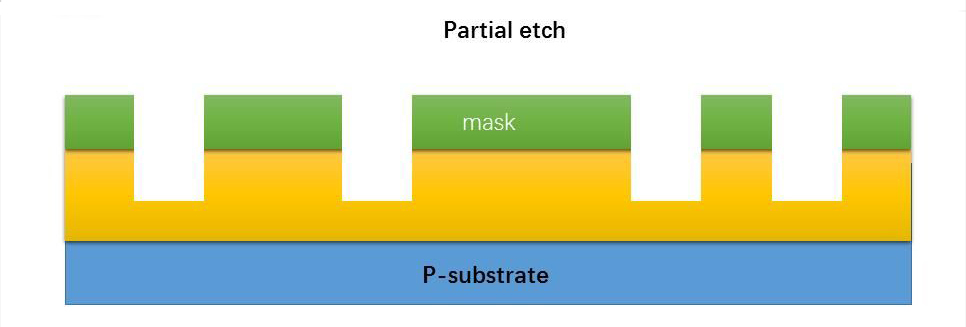

Chithunzi 2 Etching pang'ono

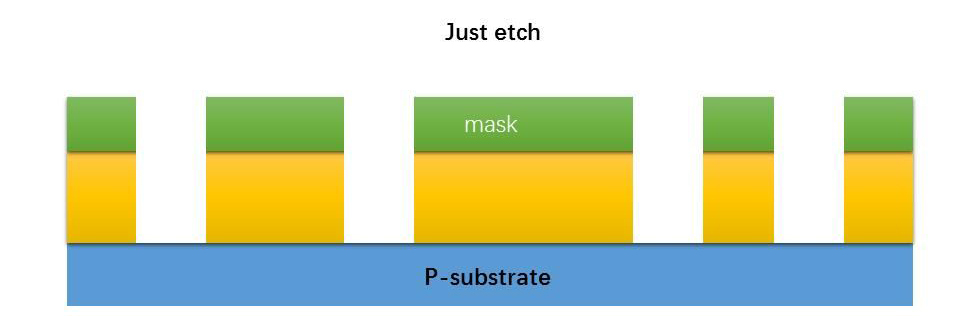

Chithunzi 3 Kungowongolera

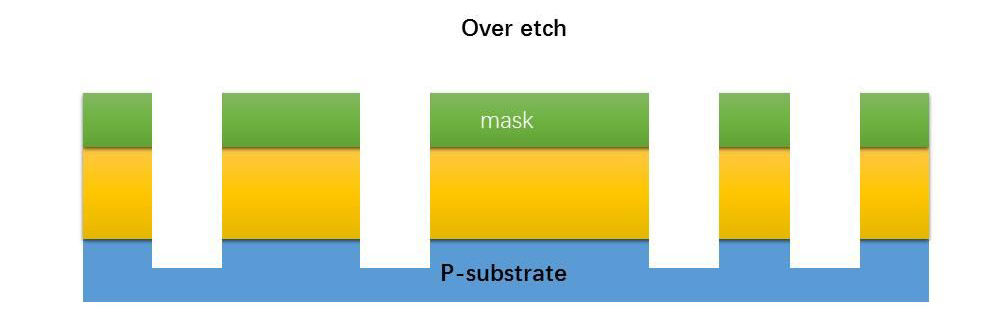

Chithunzi 4 Kuwotcha

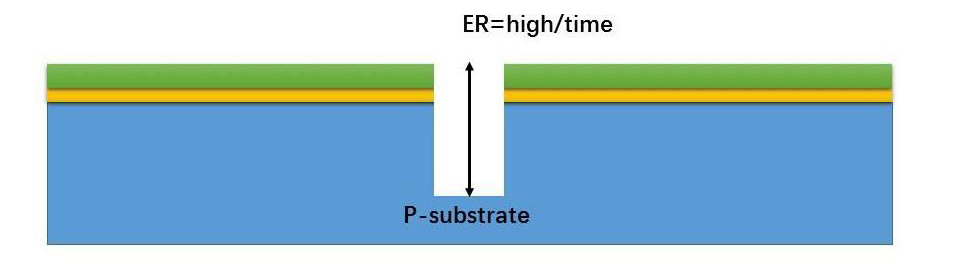

(1) Etching rate: kuya kapena makulidwe a zinthu zokhazikika zomwe zimachotsedwa panthawi imodzi.

Chithunzi 5 Etching rate rate

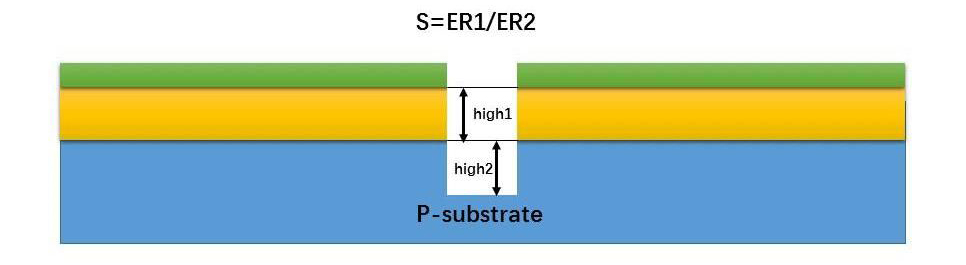

(2) Kusankhidwa: chiŵerengero cha mitengo ya etching ya zipangizo zosiyanasiyana zomangira.

Chithunzi 6 Chojambula chosankha

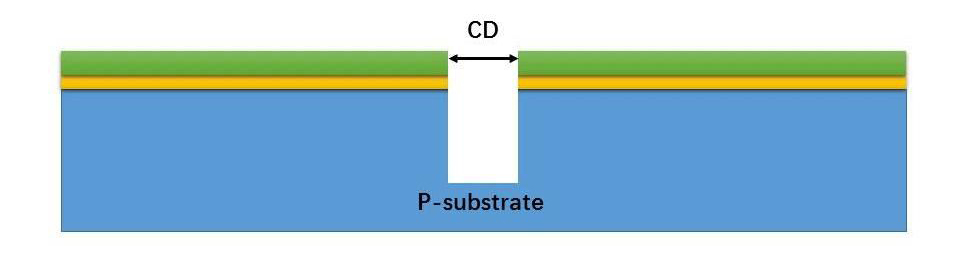

(3) Kufunika kofunikira: kukula kwa chitsanzo m'dera linalake pambuyo pomaliza.

Chithunzi 7 Chojambula chodziwika bwino

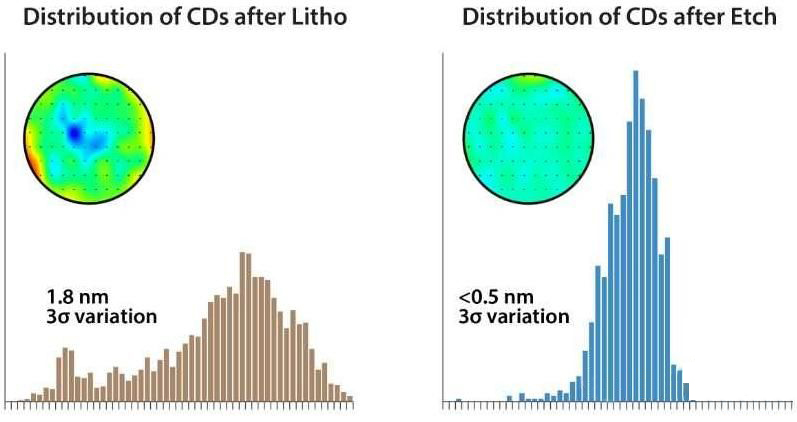

(4) Kufanana: kuyeza kufanana kwa gawo lalikulu la etching dimension (CD), lomwe nthawi zambiri limadziwika ndi mapu athunthu a CD, ndondomekoyi ndi: U=(Max-Min)/2*AVG.

Chithunzi 8 Chojambula Chofanana Chofanana

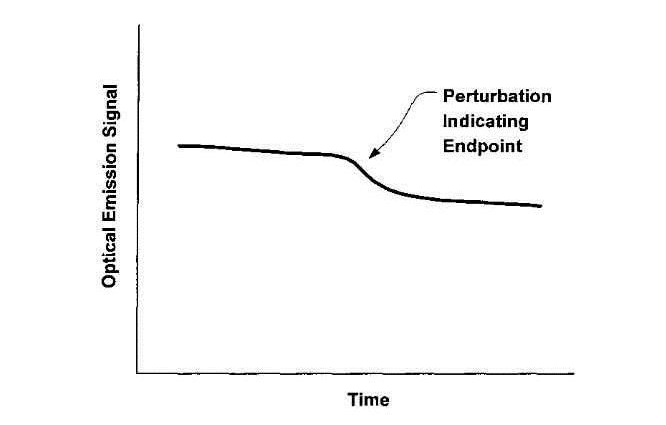

(5) Kuzindikira mfundo yomaliza: Panthawi yojambula, kusintha kwa mphamvu ya kuwala kumawonekera nthawi zonse. Kuwala kwinakwake kukakwera kapena kutsika kwambiri, kuyikako kumathetsedwa kutsimikizira kutha kwa gawo lina la kujambula filimu.

Chithunzi 9 Mapeto a chithunzi chojambula

Mu etching youma, mpweya umakondwera ndi ma frequency apamwamba (makamaka 13.56 MHz kapena 2.45 GHz). Pakukakamiza kwa 1 mpaka 100 Pa, njira yake yaulere ndi mamilimita angapo mpaka ma centimita angapo. Pali mitundu itatu yayikulu ya etching youma:

•Thupi youma etching: Imathandizira tinthu tating'onoting'ono timavala pamwamba

•Chemical dry etching: mpweya umakhudzidwa ndi mankhwala ndi pamwamba pake

•Chemical thupi youma etching: ndondomeko etching thupi ndi makhalidwe mankhwala

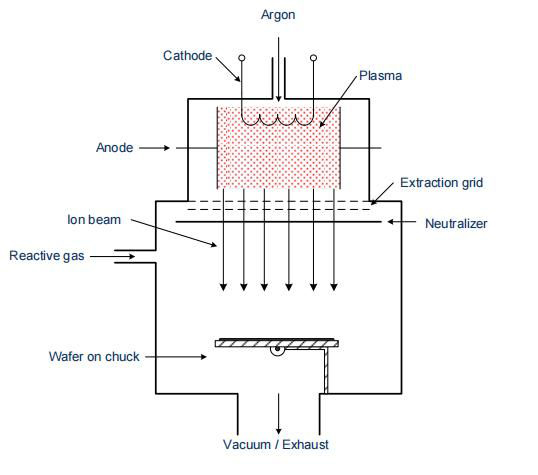

1. Kuyika mtengo wa ion

Ion beam etching (Ion Beam Etching) ndi njira yowuma yowuma yomwe imagwiritsa ntchito mtengo wa argon ion wopatsa mphamvu kwambiri wokhala ndi mphamvu pafupifupi 1 mpaka 3 keV kuyatsa zinthuzo. Mphamvu ya mtengo wa ion imapangitsa kuti ikhudze ndikuchotsa zinthu zapamtunda. The etching process ndi anisotropic pankhani ya matabwa a ion oyima kapena oblique. Komabe, chifukwa cha kusowa kwake kwa kusankha, palibe kusiyana kwakukulu pakati pa zipangizo pamagulu osiyanasiyana. The kwaiye mpweya ndi zinakhazikika zipangizo zatopa ndi vacuum mpope, koma popeza anachita mankhwala si mpweya, particles waikamo pa yopyapyala kapena chipinda makoma.

Pofuna kupewa mapangidwe a particles, mpweya wachiwiri ukhoza kulowetsedwa m'chipindamo. Mpweya uwu udzachitapo kanthu ndi ma argon ions ndikuyambitsa njira yolumikizira thupi ndi mankhwala. Gawo la gasilo lidzachitapo kanthu ndi zinthu zakuthambo, koma lidzachitanso ndi tinthu tating'onoting'ono tomwe timatulutsa mpweya. Pafupifupi mitundu yonse ya zida zitha kukhazikitsidwa ndi njira iyi. Chifukwa cha cheza chowongoka, kuvala pamakoma oyima kumakhala kochepa kwambiri (high anisotropy). Komabe, chifukwa cha kusankha kwake kochepa komanso kutsika pang'onopang'ono, njirayi sagwiritsidwa ntchito kawirikawiri popanga semiconductor yamakono.

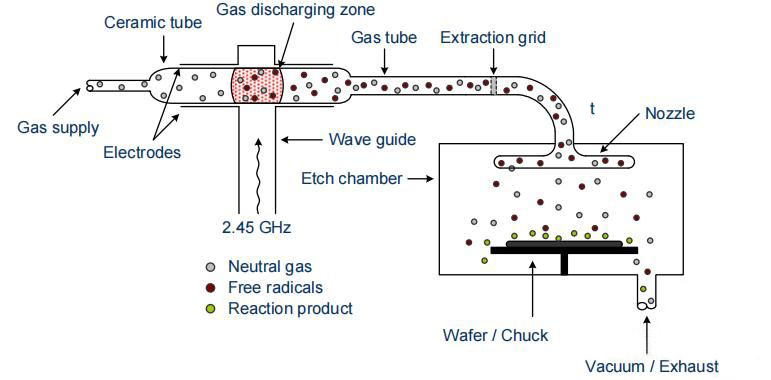

2. Kutsekemera kwa plasma

Plasma etching ndi njira yokhayo yopangira mankhwala, yomwe imatchedwanso chemical dry etching. Ubwino wake ndikuti sichimayambitsa kuwonongeka kwa ion pamtunda wosalala. Popeza kuti mitundu yogwira ntchito mu mpweya wotsekemera imakhala yaufulu kusuntha ndipo njira yowonongeka ndi isotropic, njira iyi ndi yoyenera kuchotsa filimu yonse yosanjikiza (mwachitsanzo, kuyeretsa kumbuyo pambuyo pa matenthedwe oxidation).

Chiyankhulo chakumunsi ndi mtundu wa riyakitala yomwe imagwiritsidwa ntchito popanga plasma. Mu riyakitala iyi, plasma imapangidwa ndi ionization yamphamvu mu gawo lamagetsi la 2.45GHz ndikusiyanitsidwa ndi chophatikizira.

M'dera lotulutsa mpweya, tinthu tating'onoting'ono timapangidwa chifukwa cha kukhudzidwa ndi chisangalalo, kuphatikiza ma free radicals. Ma radicals aulere ndi ma atomu osalowerera kapena mamolekyu okhala ndi ma elekitironi osakhazikika, motero amakhala otakataka. M'kati mwa plasma etching, mpweya wina wosalowerera ndale, monga tetrafluoromethane (CF4), amagwiritsidwa ntchito nthawi zambiri, omwe amalowetsedwa m'dera lotulutsa mpweya kuti apange mitundu yogwira ntchito ndi ionization kapena kuwonongeka.

Mwachitsanzo, mu mpweya wa CF4, umalowetsedwa m'dera lotulutsa mpweya ndikuwola mu fluorine radicals (F) ndi mamolekyu a carbon difluoride (CF2). Mofananamo, fluorine (F) ikhoza kuwola kuchokera ku CF4 powonjezera mpweya (O2).

2 CF4 + O2 —> 2 COF2 + 2 F2

Molekyulu ya fluorine imatha kugawika kukhala maatomu awiri odziyimira pawokha a fulorini pansi pa mphamvu ya dera lotulutsa mpweya, lililonse lomwe ndi fluorine free radical. Popeza atomu iliyonse ya fluorine ili ndi ma elekitironi asanu ndi awiri a valence ndipo imakonda kukwaniritsa kasinthidwe ka gasi wa inert, onse amakhala otakataka. Kuwonjezera ndale fulorini ufulu ankafuna kusintha zinthu mopitirira, padzakhala mlandu particles monga CF + 4, CF + 3, CF + 2, etc. mu mpweya kumaliseche dera. Pambuyo pake, tinthu tating'ono ting'onoting'ono tomwe timapanga tinthu tating'onoting'ono komanso ma free radicals amalowetsedwa m'chipinda cholumikizira kudzera mu chubu cha ceramic.

The particles mlandu akhoza oletsedwa ndi gratings m'zigawo kapena recombined m'kati kupanga ndale mamolekyulu kulamulira khalidwe lawo mu etching chipinda. Fluorine ma free radicals nawonso amapangidwanso pang'ono, koma akadali achangu mokwanira kuti alowe m'chipinda chotchingira, amachitira zinthu pamakina ophatikizika ndikuchotsa zinthu. Other ndale particles sachita nawo etching ndondomeko ndi kudyedwa pamodzi ndi anachita mankhwala.

Zitsanzo zamakanema owonda omwe amatha kuzikika mu plasma etching:

• Silikoni: Si + 4F—> SiF4

• Silicon dioxide: SiO2 + 4F—> SiF4 + O2

• Silicon nitride: Si3N4 + 12F—> 3SiF4 + 2N2

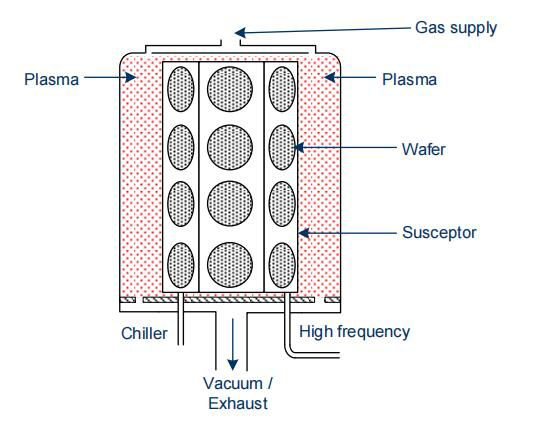

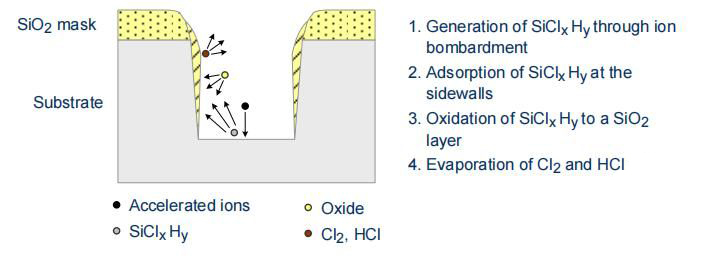

3. Reactive ion etching (RIE)

Reactive ion etching ndi njira yokhotakhota yamakina yomwe imatha kuwongolera molondola kusankha, kuyika mbiri, kuchuluka kwa etching, kufanana komanso kubwereza. Itha kukwaniritsa mbiri ya isotropic ndi anisotropic etching motero ndi imodzi mwazinthu zofunika kwambiri popanga makanema owonda osiyanasiyana popanga semiconductor.

Panthawi ya RIE, chophikacho chimayikidwa pa electrode yapamwamba kwambiri (HF electrode). Kupyolera mu ionization yamphamvu, plasma imapangidwa momwe ma elekitironi aulere ndi ma ion opangidwa bwino amakhala. Ngati mpweya wabwino umagwiritsidwa ntchito pa electrode ya HF, ma electron aulere amawunjikana pamtunda ndipo sangathe kusiyanso electrode chifukwa cha kuyanjana kwawo kwa electron. Chifukwa chake, ma elekitirodi amaperekedwa ku -1000V (voltage bias) kotero kuti ma ion apang'onopang'ono sangatsatire gawo lamagetsi lomwe likusintha mwachangu kupita ku electrode yoyipa.

Munthawi ya ion etching (RIE), ngati njira yaulere ya ayoni ndi yayikulu, imagunda pamwamba pamtunda pafupifupi perpendicular. Mwanjira iyi, ma ion othamanga amachotsa zinthuzo ndikupanga mawonekedwe amachitidwe kudzera muzolimbitsa thupi. Popeza kuti mbali zam'mbali sizikhudzidwa, mbiri ya etch imakhalabe ya anisotropic ndipo kuvala pamwamba kumakhala kochepa. Komabe, kusankha sikokwera kwambiri chifukwa njira yolumikizira thupi imachitikanso. Kuonjezera apo, kuthamanga kwa ma ion kumayambitsa kuwonongeka kwa kanyumba kakang'ono, komwe kumafuna kutentha kwa kutentha kuti kukonzedwe.

Gawo lamankhwala la etching limamalizidwa ndi ma radicals aulere omwe amakhudzidwa ndi pamwamba ndi ma ion akumenya zinthuzo kuti zisakhazikikenso pamakoma am'chipindacho, kupeŵa kukonzanso zinthu ngati chitsulo cha ion. Powonjezera mphamvu ya mpweya mu chipinda chowongolera, njira yaulere ya ayoni imachepetsedwa, zomwe zimawonjezera kuchuluka kwa mikangano pakati pa ma ion ndi mamolekyu a mpweya, ndipo ma ion amabalalika mosiyanasiyana. Izi zimabweretsa etching yocheperako, zomwe zimapangitsa kuti etching ikhale yamankhwala.

Mbiri ya anisotropic etch imatheka podutsa makoma am'mbali panthawi ya silicon etching. Oxygen imalowetsedwa m'chipinda chotchingira, momwe imayankhira ndi silikoni yokhazikika kuti ipange silicon dioxide, yomwe imayikidwa m'mbali mwake. Chifukwa cha bombardment ya ion, wosanjikiza wa oxide pamadera opingasa amachotsedwa, zomwe zimapangitsa kuti njira yolumikizirana ipitirire. Njirayi imatha kuwongolera mawonekedwe a etch mbiri komanso kutsetsereka kwa makoma am'mbali.

Mlingo wa etch umakhudzidwa ndi zinthu monga kuthamanga, mphamvu ya jenereta ya HF, gasi wopangira, kutsika kwa gasi weniweni ndi kutentha kwawafa, ndipo kusiyanasiyana kwake kumasungidwa pansi pa 15%. Anisotropy imachulukirachulukira ndikuwonjezera mphamvu ya HF, kutsitsa kuthamanga komanso kuchepa kwa kutentha. Kufanana kwa njira ya etching kumatsimikiziridwa ndi mpweya, ma electrode spacing ndi electrode material. Ngati mtunda wa electrode ndi wochepa kwambiri, plasma singakhoze kumwazikana mofanana, zomwe zimapangitsa kuti zikhale zosiyana. Kuchulukitsa mtunda wa electrode kumachepetsa kuchuluka kwa etching chifukwa plasma imagawidwa mokulirapo. Mpweya ndi chinthu chomwe chimakondedwa ndi electrode chifukwa chimapanga plasma yosakanikirana kotero kuti m'mphepete mwa mtandawo umakhudzidwa mofanana ndi pakati pa mtanda.

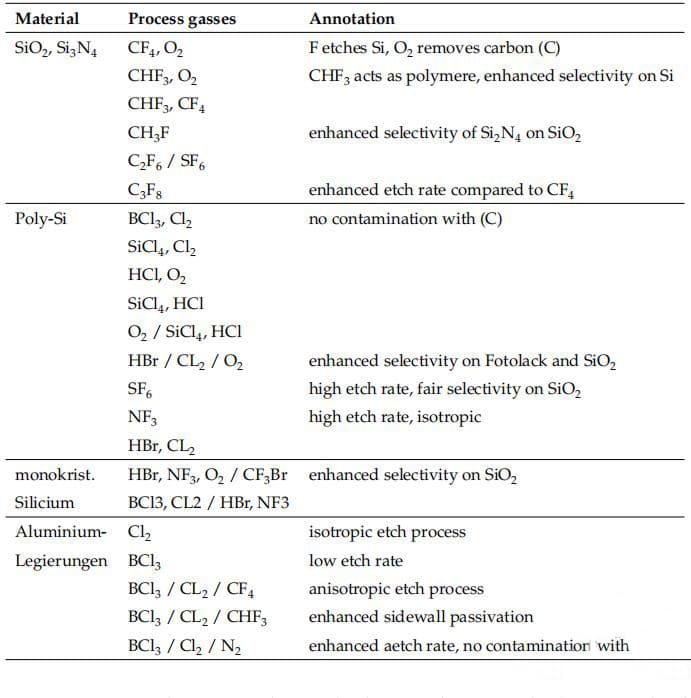

The ndondomeko mpweya kumathandiza kwambiri selectivity ndi etching mlingo. Pazinthu za silicon ndi silicon, fluorine ndi klorini amagwiritsidwa ntchito makamaka kuti akwaniritse etching. Kusankha mpweya woyenerera, kusintha kayendedwe ka gasi ndi kupanikizika, ndi kulamulira magawo ena monga kutentha ndi mphamvu mu ndondomekoyi kungathe kukwaniritsa mlingo wofunikila, kusankha, ndi kufanana. Kukhathamiritsa kwa magawowa nthawi zambiri kumasinthidwa pazogwiritsa ntchito ndi zida zosiyanasiyana.

Njira yopangira etching sikuti imangokhala ndi mpweya umodzi, kusakaniza kwa gasi, kapena magawo okhazikika. Mwachitsanzo, oxide yachilengedwe pa polysilicon imatha kuchotsedwa koyamba ndi kuchuluka kwa etch komanso kutsika kochepa, pomwe polysilicon imatha kukhazikitsidwa pambuyo pake ndi kusankha kwapamwamba kogwirizana ndi zigawo zapansi.

—————————————————————————————————————————————————— ————————————

Semicera ikhoza kuperekazigawo za graphite, zofewa/zokhazikika, zida za silicon carbide,Zigawo za CVD silicon carbide,ndiZigawo zokutira za SiC/TaC ndi m'masiku 30.

Ngati mukufuna zinthu za semiconductor pamwambapa,chonde musazengereze kulumikizana nafe nthawi yoyamba.

Tel: +86-13373889683

Watsapp: +86-15957878134

Email: sales01@semi-cera.com

Nthawi yotumiza: Sep-12-2024