Popanga semiconductor, pali njira yotchedwa "etching" panthawi yokonza gawo lapansi kapena filimu yopyapyala yomwe imapangidwa pa gawo lapansi. Kukula kwaukadaulo wa etching kwathandizira kukwaniritsidwa koneneratu konenedwa ndi woyambitsa Intel Gordon Moore mu 1965 kuti "kuphatikizana kwa ma transistors kudzawirikiza kawiri muzaka 1.5 mpaka 2" (omwe amadziwika kuti "Moore's Law").

Etching si njira "yowonjezera" monga kuyika kapena kulumikiza, koma njira "yochotsera". Kuphatikiza apo, molingana ndi njira zosiyanasiyana zokhwasula, zimagawidwa m'magulu awiri, omwe ndi "wonyowa etching" ndi "dry etching". Kunena mwachidule, yoyamba ndi njira yosungunula ndipo yotsirizira ndi njira yokumba.

M'nkhaniyi, tifotokoza mwachidule makhalidwe ndi kusiyana kwa teknoloji iliyonse ya etching, etching yonyowa ndi etching youma, komanso malo ogwiritsira ntchito omwe aliyense ali woyenera.

Chidule cha etching process

Tekinoloje ya etching akuti idachokera ku Europe chapakati pazaka za zana la 15. Panthawiyo, asidi amatsanuliridwa mu mbale yamkuwa yozokota kuti awononge mkuwa wopanda kanthu, kupanga intaglio. Njira zochizira pamwamba zomwe zimagwiritsa ntchito kuwonongeka kwa dzimbiri zimadziwika kuti "etching."

Cholinga cha etching process popanga semiconductor ndikudula gawo lapansi kapena filimu pagawolo malinga ndi zojambulazo. Pobwereza masitepe okonzekera kupanga filimu, photolithography, ndi etching, dongosolo la planar limakonzedwa kukhala mawonekedwe atatu.

Kusiyana pakati pa etching yonyowa ndi etching youma

Pambuyo pa ndondomeko ya photolithography, gawo lapansi lowonekera limakhala lonyowa kapena louma lokhazikika pakupanga.

Chonyowa chonyowa chimagwiritsa ntchito njira yopopera ndikuchotsa pamwamba. Ngakhale njirayi imatha kukonzedwa mwachangu komanso motsika mtengo, choyipa chake ndikuti kulondola kwadongosolo kumatsika pang'ono. Chifukwa chake, etching youma idabadwa cha m'ma 1970. Dry etching sigwiritsa ntchito yankho, koma imagwiritsa ntchito gasi kugunda gawo lapansi kuti likande, lomwe limadziwika ndi kulondola kwambiri.

"Isotropy" ndi "Anisotropy"

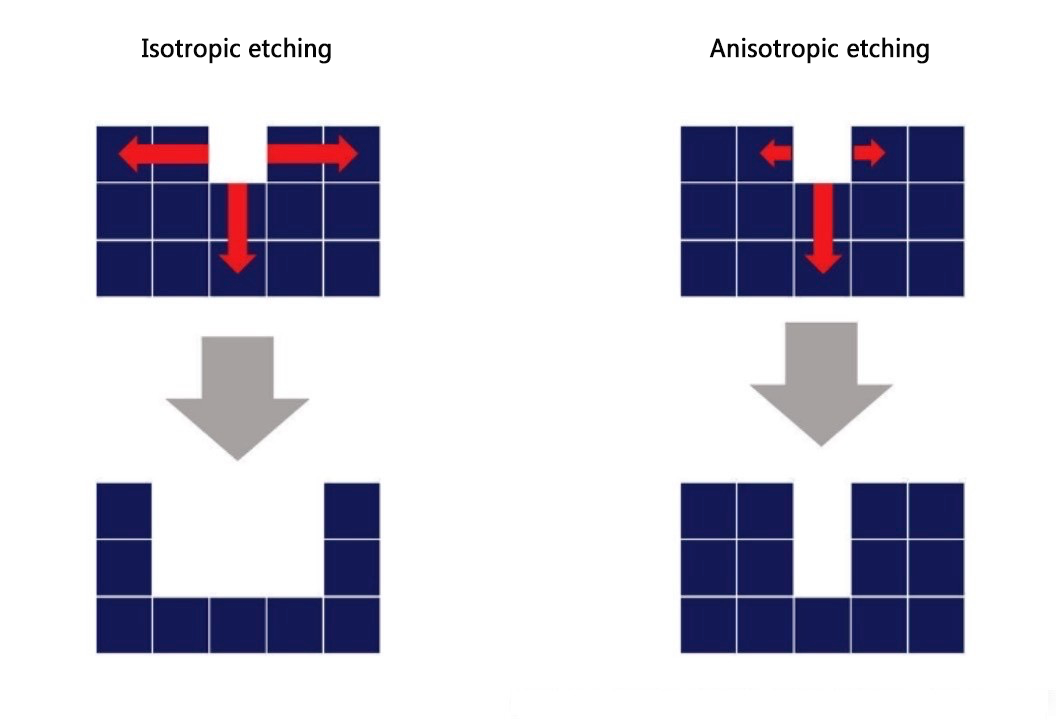

Poyambitsa kusiyana pakati pa kunyowa kwanyowa ndi kukokera kowuma, mawu ofunikira ndi "isotropic" ndi "anisotropic". Isotropy imatanthawuza kuti zinthu zakuthupi za zinthu ndi danga sizisintha ndi malangizo, ndipo anisotropy imatanthauza kuti zinthu zakuthupi ndi mlengalenga zimasiyana ndi malangizo.

Isotropic etching imatanthawuza kuti etching imapitilira mulingo womwewo kuzungulira malo enaake, ndipo etching ya anisotropic imatanthawuza kuti etching imapita mbali zosiyanasiyana kuzungulira mfundo inayake. Mwachitsanzo, pakupanga ma semiconductor, etching ya anisotropic nthawi zambiri imasankhidwa kuti malo omwe akulowera okhawo amasulidwe, kusiya mbali zina.

Zithunzi za "Isotropic Etch" ndi "Anisotropic Etch"

Zithunzi za "Isotropic Etch" ndi "Anisotropic Etch"

Kunyowa konyowa pogwiritsa ntchito mankhwala.

Kunyowa kumagwiritsa ntchito kusintha kwa mankhwala pakati pa mankhwala ndi gawo lapansi. Ndi njira iyi, kukokera kwa anisotropic sikutheka, koma ndikovuta kwambiri kuposa kukodza kwa isotropic. Pali zoletsa zambiri pakuphatikiza mayankho ndi zida, ndipo mikhalidwe monga kutentha kwa gawo lapansi, ndende ya yankho, ndi kuchuluka kwake ziyenera kuyendetsedwa mosamalitsa.

Ziribe kanthu momwe mikhalidwe imasinthidwira bwino, kukokera konyowa kumakhala kovuta kukwaniritsa kukonza bwino pansi pa 1 μm. Chifukwa chimodzi cha izi ndi kufunikira kowongolera mbali zowongolera.

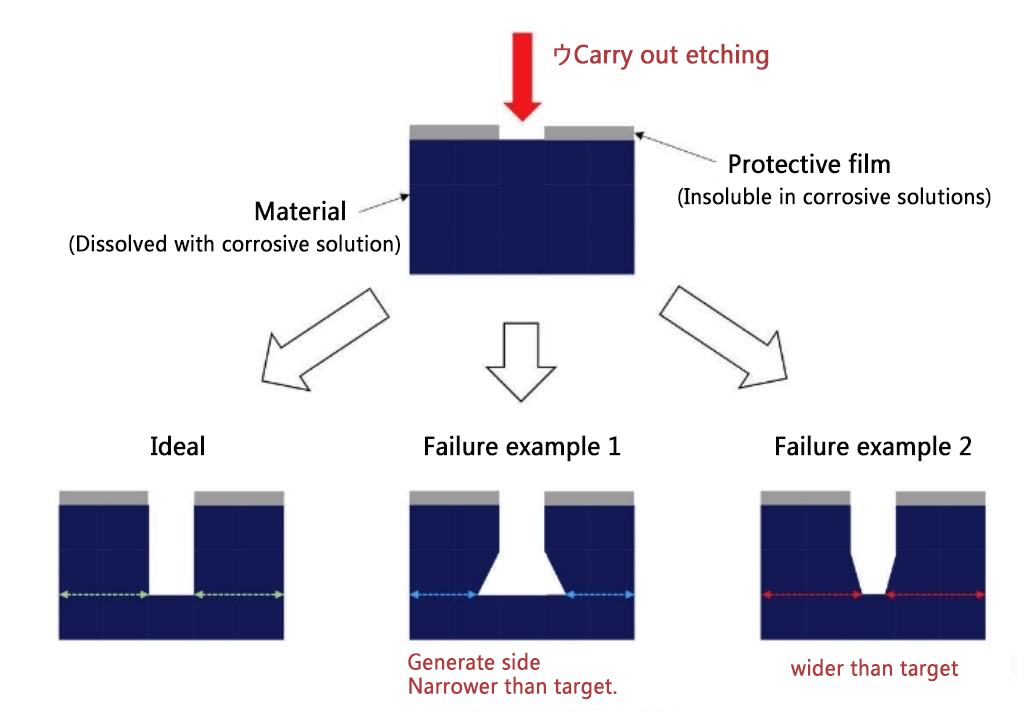

Undercutting ndi chinthu chomwe chimatchedwanso undercutting. Ngakhale tikuyembekeza kuti zinthuzo zidzasungunuka molunjika (kuzama kwakuya) ndi kutsekemera konyowa, sikutheka kulepheretsa njira yothetsera kugunda m'mbali, kotero kuti kusungunuka kwa zinthuzo motsatira njira yofanana kudzapitirirabe. . Chifukwa cha chodabwitsa ichi, kunyowa konyowa kumapanga magawo ocheperapo kuposa omwe mukufuna. Mwanjira imeneyi, pokonza zinthu zomwe zimafuna kuwongolera bwino, kuberekako kumakhala kochepa ndipo kulondola sikudalirika.

Zitsanzo za Zolephera Zomwe Zingachitike mu Wet Etching

Zitsanzo za Zolephera Zomwe Zingachitike mu Wet Etching

Chifukwa chiyani etching youma ndi yoyenera kwa micromachining

Kufotokozera kwa Related Art Dry etching yoyenera kwa anisotropic etching imagwiritsidwa ntchito popanga ma semiconductor omwe amafunikira kukonzedwa bwino kwambiri. Dry etching nthawi zambiri imatchedwa reactive ion etching (RIE), yomwe ingaphatikizepo etching ya plasma ndi sputter etching mwatsatanetsatane, koma nkhaniyi ifotokoza za RIE.

Kuti tifotokoze chifukwa chake etching ya anisotropic ndiyosavuta ndi etching youma, tiyeni tiwone mwatsatanetsatane njira ya RIE. Ndizosavuta kuzimvetsetsa pogawa njira yowuma ndikuchotsa gawolo kukhala mitundu iwiri: "chemical etching" ndi "physical etching".

Chemical etching imachitika mu masitepe atatu. Choyamba, mipweya yotulutsa mpweya imatulutsidwa pamwamba. Zomwe zimapangidwira zimapangidwa kuchokera ku zomwe gasi ndi zinthu zapansi panthaka, ndipo pamapeto pake zomwe zimapangidwira zimadetsedwa. M'malo olumikizirana, gawo lapansi limakhazikika pansi ndikuyika mpweya wa argon molunjika ku gawo lapansi.

Chemical etching imachitika isotropically, pomwe kuwotcha kwakuthupi kumatha kuchitika mwachilengedwe poyang'anira komwe gasi amapangira. Chifukwa cha kukhazikika kwakuthupi uku, kuyanika kowuma kumalola kuwongolera komwe kumalowera kuposa kukokera konyowa.

Kuwotchera kowuma komanso konyowa kumafunikiranso mikhalidwe yokhwima yofanana ndi kukokera konyowa, koma kumakhala ndi kuberekana kochulukirapo kuposa kukokera konyowa ndipo kumakhala ndi zinthu zambiri zosavuta kuziwongolera. Choncho, palibe kukayikira kuti kuuma kowuma kumathandiza kwambiri kupanga mafakitale.

Chifukwa Chake Kunyowa Kumafunikabe

Mukamvetsetsa zowuma zowoneka ngati zamphamvu zonse, mutha kudabwa chifukwa chake kukokera konyowa kudalipobe. Komabe, chifukwa chake ndi chosavuta: kunyowa konyowa kumapangitsa kuti mtengowo ukhale wotsika mtengo.

Kusiyana kwakukulu pakati pa etching youma ndi etching yonyowa ndi mtengo. Mankhwala omwe amagwiritsidwa ntchito ponyowa siwokwera mtengo kwambiri, ndipo mtengo wa chipangizocho akuti ndi pafupifupi 1/10 wa zida zowuma. Kuphatikiza apo, nthawi yokonza ndi yochepa ndipo magawo angapo amatha kukonzedwa nthawi imodzi, kuchepetsa ndalama zopangira. Zotsatira zake, titha kusunga ndalama zotsika mtengo, zomwe zimatipatsa mwayi kuposa omwe timapikisana nawo. Ngati zofunika pakukonza molondola sizili zapamwamba, makampani ambiri amasankha kunyowa konyowa kuti apange misa yambiri.

Njira yopangira etching idayambitsidwa ngati njira yomwe imagwira ntchito muukadaulo wa microfabrication. Njira yopangira etching imagawidwa kukhala etching yonyowa ndi etching youma. Ngati mtengo ndi wofunikira, woyamba ndi wabwino, ndipo ngati microprocessing pansi pa 1 μm ikufunika, yotsirizirayo ndi yabwino. Momwemo, njira ingasankhidwe potengera zomwe zimapangidwira komanso mtengo wake, m'malo motengera zomwe zili bwino.

Nthawi yotumiza: Apr-16-2024