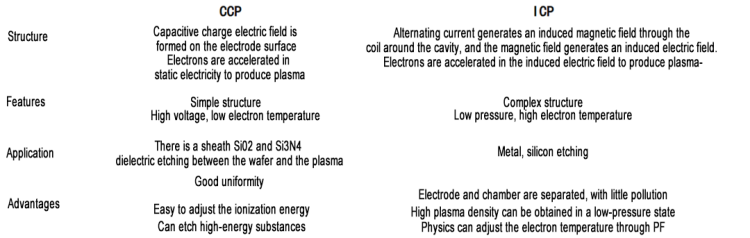

Pakupanga semiconductor,etchingteknoloji ndi njira yovuta yomwe imagwiritsidwa ntchito kuchotsa ndendende zinthu zosafunikira pa gawo lapansi kuti apange machitidwe ozungulira ovuta. Nkhaniyi ifotokoza mwatsatanetsatane matekinoloje awiri odziwika bwino - kuphatikiza plasma etching (CCP) komanso kuphatikiza plasma etching (ICP), ndikuwunika momwe amagwiritsira ntchito polemba zida zosiyanasiyana.

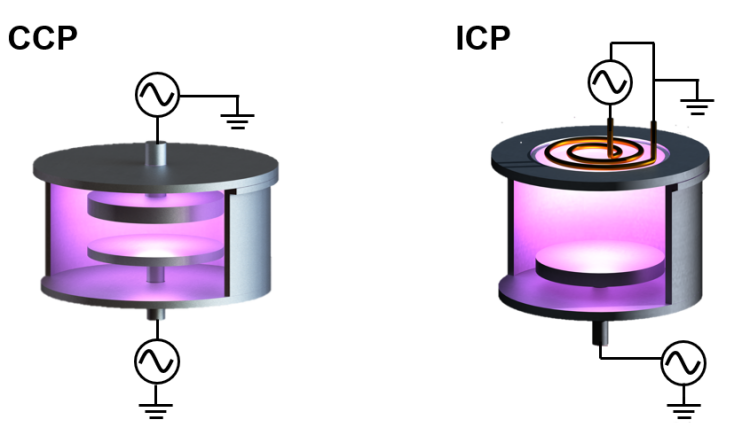

Kuphatikiza kwa plasma etching (CCP)

Capacitively coupled plasma etching (CCP) imatheka pogwiritsa ntchito magetsi a RF ku maelekitirodi a mbale ziwiri zofananira kudzera pa matcher ndi DC blocking capacitor. Ma electrodes awiri ndi plasma pamodzi amapanga capacitor yofanana. Pochita izi, magetsi a RF amapanga sheath capacitive pafupi ndi electrode, ndipo malire a sheath amasintha ndi kuthamanga kwachangu kwa voliyumu. Ma electron akafika m'chimake chosintha mofulumirachi, amawonetsedwa ndikupeza mphamvu, zomwe zimayambitsa kupatukana kapena ionization ya mamolekyu a gasi kuti apange plasma. CCP etching nthawi zambiri imagwiritsidwa ntchito kuzinthu zokhala ndi mphamvu zambiri zomangira mankhwala, monga ma dielectrics, koma chifukwa cha kuchepa kwake, ndizoyenera kugwiritsa ntchito zomwe zimafunikira kuwongolera bwino.

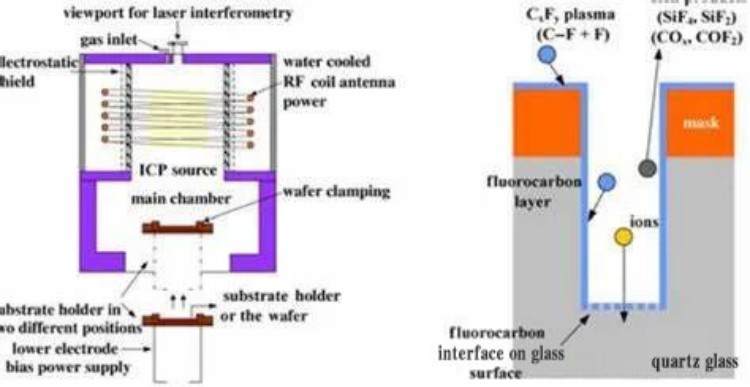

Kuphatikiza kwa plasma etching (ICP)

Kuphatikizidwa kwa plasmaetching(ICP) imachokera pa mfundo yakuti magetsi osinthasintha amadutsa pa koyilo kuti apange mphamvu ya maginito. Pansi pa mphamvu ya maginitoyi, ma electron omwe ali mu chipinda chochitiramo amafulumizitsa ndikupitiriza kuthamangira kumalo opangira magetsi, ndipo pamapeto pake amamenyana ndi mamolekyu a gasi, zomwe zimapangitsa kuti mamolekyu asokonezeke kapena ionize ndikupanga plasma. Njirayi imatha kupanga kuchuluka kwa ionization ndikulola kuti kachulukidwe ka plasma ndi bombardment mphamvu zisinthidwe paokha, zomwe zimapangitsaKusintha kwa ICPoyenera kwambiri etching zipangizo ndi otsika mankhwala chomangira mphamvu, monga pakachitsulo ndi zitsulo. Kuphatikiza apo, ukadaulo wa ICP umaperekanso kufanana kwabwinoko komanso kuchuluka kwa etching.

1. Kujambula zitsulo

Chitsulo etching makamaka ntchito processing wa interconnects ndi Mipikisano wosanjikiza mawaya zitsulo. Zofunikira zake zikuphatikiza: kutsika kwakukulu, kusankha kwakukulu (kuposa 4: 1 kwa wosanjikiza wa chigoba ndi wamkulu kuposa 20: 1 ya dielectric ya interlayer), kufanana kwakukulu, kuwongolera kwabwino kofunikira, kusawonongeka kwa plasma, zowononga zotsalira, ndi palibe dzimbiri ku zitsulo. Kuyika kwachitsulo nthawi zambiri kumagwiritsa ntchito zida zolumikizirana ndi plasma.

•Aluminium etching: Aluminiyamu ndiye chinthu chofunikira kwambiri chawaya pakati ndi kumbuyo kwa ma chip opanga, ndi zabwino za kukana kutsika, kuyika kosavuta komanso kukokera. Aluminium etching nthawi zambiri amagwiritsa ntchito plasma yopangidwa ndi mpweya wa chloride (monga Cl2). Aluminiyamu imakumana ndi klorini kupanga volatile aluminium chloride (AlCl3). Komanso, ena halides monga SiCl4, BCl3, Bbr3, CCl4, CHF3, etc. akhoza kuwonjezeredwa kuchotsa okusayidi wosanjikiza pamwamba zotayidwa kuonetsetsa etching yachibadwa.

• Tungsten etching: Muzinthu zolumikizira waya zazitsulo zamitundu yambiri, tungsten ndiye chitsulo chachikulu chomwe chimagwiritsidwa ntchito polumikiza gawo lapakati la chip. Mipweya yochokera ku fluorine kapena chlorine imatha kugwiritsidwa ntchito kuyika zitsulo za tungsten, koma mipweya yochokera ku fluorine imakhala yosasankha bwino pa silicon oxide, pomwe mipweya yochokera ku chlorine (monga CCl4) imasankha bwino. Nayitrojeni nthawi zambiri amawonjezedwa ku gasi kuti azitha kusankha guluu wapamwamba kwambiri, ndipo mpweya umawonjezeredwa kuti muchepetse mpweya. Etching tungsten yokhala ndi chlorine-based gasi imatha kukwaniritsa etching ya anisotropic komanso kusankha kwakukulu. Mipweya yomwe imagwiritsidwa ntchito poyika tungsten youma ndi SF6, Ar ndi O2, yomwe SF6 imatha kuwola mu plasma kuti ipereke maatomu a fluorine ndi tungsten kuti apange mankhwala kuti apange fluoride.

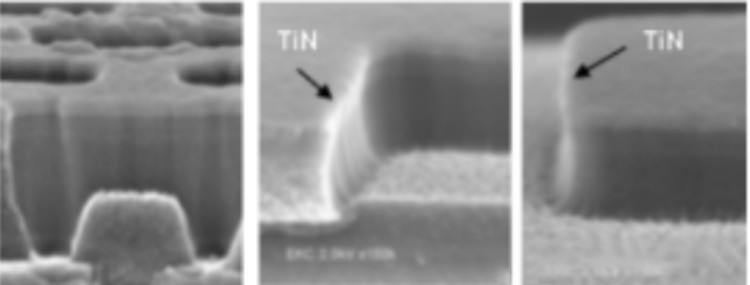

• Titaniyamu nitride etching: Titanium nitride, monga chigoba cholimba, imalowa m'malo mwa chikhalidwe cha silicon nitride kapena oxide mask mu njira ziwiri za damascene. Titanium nitride etching imagwiritsidwa ntchito kwambiri potsegula chigoba cholimba, ndipo chinthu chachikulu ndi TiCl4. Kusankhidwa pakati pa chigoba chachikhalidwe ndi otsika-k dielectric wosanjikiza sipamwamba, zomwe zidzatsogolera maonekedwe a mawonekedwe a arc pamwamba pa otsika-k dielectric wosanjikiza ndi kukulitsa kwa groove m'lifupi pambuyo etching. Kutalikirana pakati pa mizere yachitsulo yoyikidwa ndi yaying'ono kwambiri, yomwe imakonda kutayikira kapena kusweka mwachindunji.

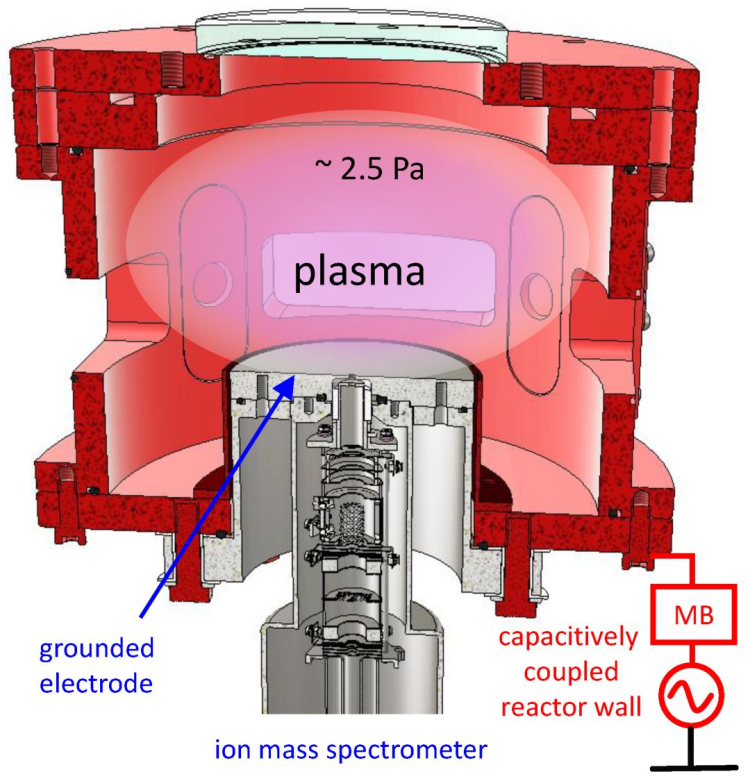

2. Insulator etching

Chinthu cha insulator etching nthawi zambiri ndi zida za dielectric monga silicon dioxide kapena silicon nitride, zomwe zimagwiritsidwa ntchito kwambiri kupanga mabowo olumikizana ndi mabowo olumikizirana kuti alumikizane zigawo zosiyanasiyana. Etching ya dielectric nthawi zambiri imagwiritsa ntchito etcher potengera mfundo ya capacitively cophant plasma etching.

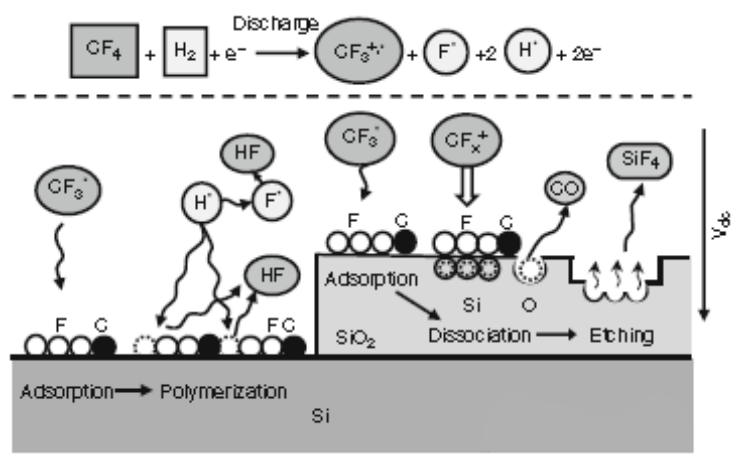

• Plasma etching of silicon dioxide film: Silicon dioxide filimu nthawi zambiri amazikika pogwiritsa ntchito etching mpweya wokhala fluorine, monga CF4, CHF3, C2F6, SF6 ndi C3F8. Mpweya womwe uli mu mpweya wotsekemera ukhoza kuchitapo kanthu ndi mpweya womwe uli mu oxide wosanjikiza kuti upangitse CO ndi CO2, potero kuchotsa mpweya mu oxide wosanjikiza. CF4 ndiye mpweya wogwiritsidwa ntchito kwambiri. CF4 ikagundana ndi ma elekitironi amphamvu kwambiri, ma ion osiyanasiyana, ma radicals, ma atomu ndi ma radicals aulere amapangidwa. Fluorine free radicals amatha kuchitapo kanthu ndi SiO2 ndi Si kuti apange silicon tetrafluoride (SiF4) yosasinthika.

• Kupaka filimu ya silicon nitride ya Plasma: Filimu ya silicon nitride ikhoza kukhazikitsidwa pogwiritsa ntchito plasma etching ndi CF4 kapena CF4 gasi wosakanikirana (ndi O2, SF6 ndi NF3). Kwa filimu ya Si3N4, pamene madzi a m'magazi a CF4-O2 kapena madzi ena a m'magazi omwe ali ndi maatomu a F amagwiritsidwa ntchito pojambula, mlingo wa etching wa silicon nitride ukhoza kufika 1200Å/min, ndipo etching selectivity ikhoza kufika pa 20:1. Chogulitsa chachikulu ndi chosakhazikika cha silicon tetrafluoride (SiF4) chomwe ndi chosavuta kutulutsa.

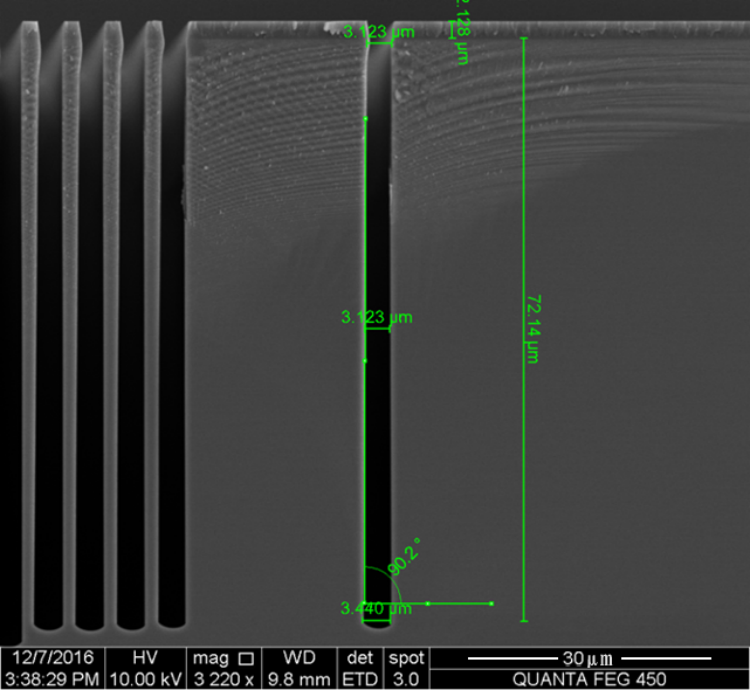

3. Single crystal silicon etching

Single crystal silicon etching imagwiritsidwa ntchito kwambiri kupanga shallow trench isolation (STI). Njirayi nthawi zambiri imakhala ndi njira yopambana komanso njira yayikulu yolumikizira. Njira yopambana imagwiritsa ntchito mpweya wa SiF4 ndi NF kuchotsa oxide wosanjikiza pamwamba pa silicon imodzi ya crystal kupyolera mu bombardment yamphamvu ya ion ndi zochita za mankhwala a fluorine elements; kuunika kwakukulu kumagwiritsa ntchito hydrogen bromide (HBr) monga cholumikizira chachikulu. Ma radicals a bromine omwe amawola ndi HBr m'malo a plasma amachitira ndi silicon kuti apange silicon tetrabromide (SiBr4), potero amachotsa silicon. Single crystal silicon etching nthawi zambiri imagwiritsa ntchito makina ojambulira a plasma.

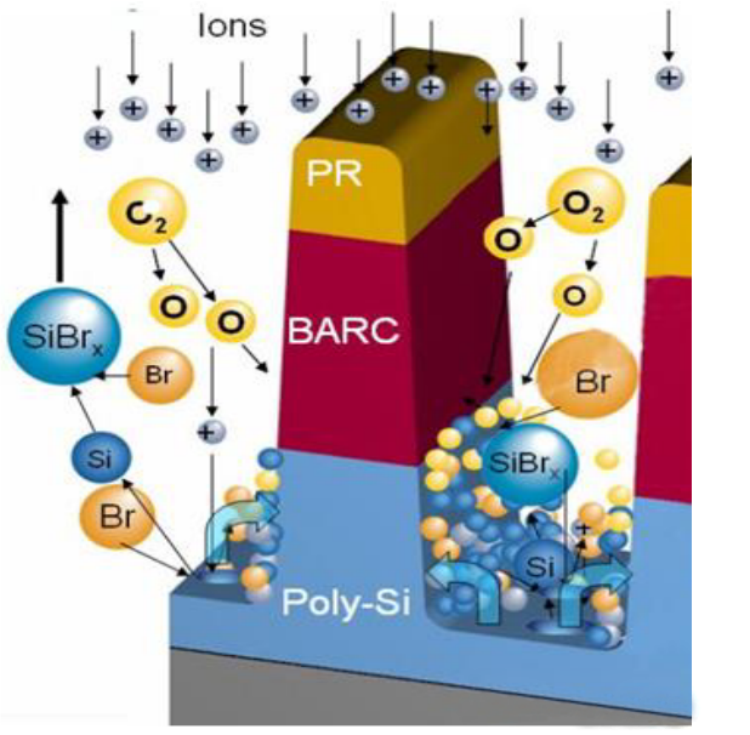

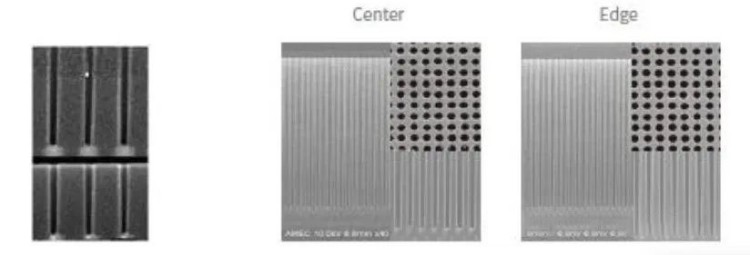

4. Polysilicon Etching

Polysilicon etching ndi imodzi mwazinthu zazikulu zomwe zimatsimikizira kukula kwa chipata cha transistors, ndipo kukula kwa chipata kumakhudza mwachindunji magwiridwe antchito ophatikizika. Polysilicon etching imafuna chiŵerengero chabwino cha kusankha. Mpweya wa halogen monga chlorine (Cl2) nthawi zambiri amagwiritsidwa ntchito kuti akwaniritse etching ya anisotropic, ndikukhala ndi chiŵerengero chabwino cha selectivity (mpaka 10: 1). Mipweya yochokera ku bromine monga hydrogen bromide (HBr) imatha kupeza chiŵerengero chapamwamba cha kusankha (mpaka 100: 1). Kusakaniza kwa HBr ndi klorini ndi okosijeni kumatha kuwonjezera kuchuluka kwa etching. Zomwe zimapangidwa ndi gasi wa halogen ndi silicon zimayikidwa pambali kuti ziteteze. Polysilicon etching nthawi zambiri imagwiritsa ntchito makina ojambulira a plasma.

Kaya ndikulumikizana mwamphamvu kwa plasma kapena kulumikizidwa molumikizana kwa plasma, chilichonse chili ndi zabwino zake komanso mawonekedwe ake. Kusankha umisiri woyenera etching sikungangowonjezera luso la kupanga, komanso kuwonetsetsa kuti zokolola zomaliza zimaperekedwa.

Nthawi yotumiza: Nov-12-2024