Silicon carbide (SiC) epitaxy

The epitaxial tray, yomwe imakhala ndi gawo la SiC lokulitsa kagawo ka SiC epitaxial, imayikidwa mu chipinda chochitiramo ndikulumikizana mwachindunji ndi chophikacho.

Gawo lapamwamba la theka la mwezi ndi chonyamulira zida zina za chipinda chochitiramo cha Sic epitaxy zida, pomwe gawo laling'ono la theka la mwezi limalumikizidwa ndi chubu cha quartz, ndikuyambitsa mpweya woyendetsa susceptor base kuti azungulira. iwo ndi kutentha-controllable ndipo anaika mu anachita chipinda popanda kukhudzana mwachindunji ndi mkate.

Ndi epitaxy

Thireyi, yomwe imakhala ndi gawo la Si pokulitsa kagawo ka Si epitaxial, imayikidwa m'chipinda chochitiramo ndikulumikizana mwachindunji ndi mkatewo.

Mphete yotenthetsera imakhala pamphete yakunja ya tray ya Si epitaxial substrate ndipo imagwiritsidwa ntchito pakuwongolera ndi kutentha. Imayikidwa mu chipinda chochitiramo ndipo sichimalumikizana mwachindunji ndi mkatewo.

Epitaxial susceptor, yomwe imakhala ndi gawo la Si pokulitsa kagawo kakang'ono ka Si epitaxial, loyikidwa muchipinda chochitiramo ndikulumikizana mwachindunji ndi mkatewo.

Epitaxial barrel ndi zigawo zikuluzikulu zomwe zimagwiritsidwa ntchito m'njira zosiyanasiyana zopangira semiconductor, zomwe zimagwiritsidwa ntchito pazida za MOCVD, zokhala ndi kutentha kwabwino kwambiri, kukana kwa mankhwala ndi kukana kuvala, zoyenera kwambiri kugwiritsidwa ntchito pa kutentha kwakukulu. Imakhudzana ndi zophika.

| Zakuthupi za Recrystallized Silicon Carbide | |

| Katundu | Mtengo Wodziwika |

| Kutentha kogwira ntchito (°C) | 1600°C (ndi mpweya), 1700°C (kuchepetsa chilengedwe) |

| Zinthu za SiC | 99.96% |

| Zaulere za Si | <0.1% |

| Kuchulukana kwakukulu | 2.60-2.70 g/cm3 |

| Zowoneka porosity | < 16% |

| Kupanikizika kwamphamvu | > 600 MPa |

| Kuzizira kopinda mphamvu | 80-90 MPa (20°C) |

| Mphamvu yopindika yotentha | 90-100 MPa (1400°C) |

| Kukula kwa kutentha pa 1500°C | 4.70 10-6/°C |

| Thermal conductivity @ 1200 ° C | 23 W/m•K |

| Elastic moduli | 240 GPA |

| Thermal shock resistance | Zabwino kwambiri |

| Zakuthupi za Sintered Silicon Carbide | |

| Katundu | Mtengo Wodziwika |

| Chemical Composition | SiC>95%, Si<5% |

| Kuchulukana Kwambiri | >3.07g/cm³ |

| Zowoneka porosity | <0.1% |

| Modulus yophulika pa 20 ℃ | 270 MPa |

| Modulus yophulika pa 1200 ℃ | 290 MPa |

| Kulimba pa 20 ℃ | 2400 Kg / mm² |

| Kulimba kwa Fracture pa 20% | 3.3 MPa · m1/2 |

| Thermal Conductivity pa 1200 ℃ | 45 w/m.K |

| Kukula kwamafuta pa 20-1200 ℃ | 4.5 1 × 10 -6/℃ |

| Kutentha kwakukulu | 1400 ℃ |

| Thermal shock resistance pa 1200 ℃ | Zabwino |

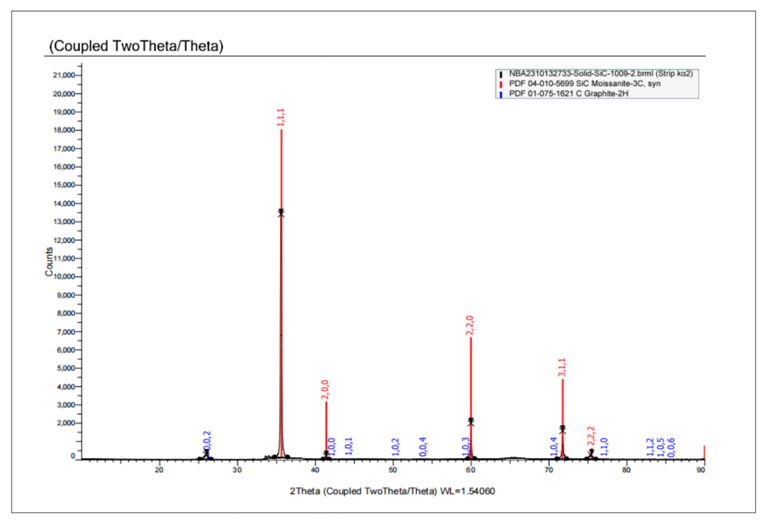

| Zofunikira zenizeni zamakanema a CVD SiC | |

| Katundu | Mtengo Wodziwika |

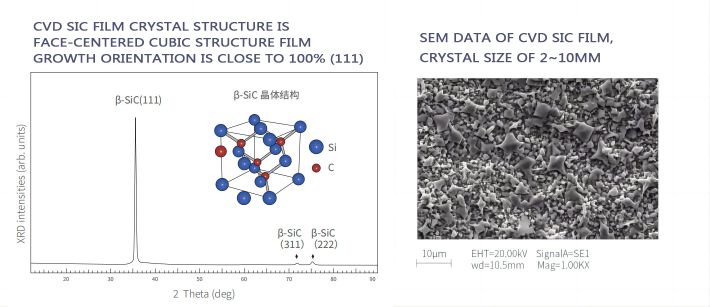

| Kapangidwe ka Crystal | FCC β gawo polycrystalline, makamaka (111) yolunjika |

| Kuchulukana | 3.21g/cm³ |

| Kulimba 2500 | (500g katundu) |

| Ukulu wa Mbewu | 2 ~ 10μm |

| Chemical Purity | 99.99995% |

| Kutentha Mphamvu | 640 jkg-1·K-1 |

| Kutentha kwa Sublimation | 2700 ℃ |

| Flexural Mphamvu | 415 MPa RT 4-mfundo |

| Young's Modulus | 430 Gpa 4pt bend, 1300 ℃ |

| Thermal Conductivity | 300Wm-1·K-1 |

| Kukula kwa Thermal (CTE) | 4.5 × 10-6 K -1 |

Mbali zazikulu

Pamwamba pake ndi wandiweyani komanso wopanda pores.

Kuyeretsedwa kwakukulu, zonyansa zonse <20ppm, mpweya wabwino.

Kutentha kwakukulu kwa kutentha, mphamvu kumawonjezeka ndi kutentha kwa ntchito, kufika pamtengo wapamwamba kwambiri pa 2750 ℃, sublimation pa 3600 ℃.

Low elastic modulus, mkulu matenthedwe madutsidwe, kutsika kwamphamvu kukulitsa coefficient, komanso kukana kwamphamvu kwamatenthedwe.

Good mankhwala bata, kugonjetsedwa ndi asidi, zamchere, mchere, ndi organic reagents, ndipo alibe mphamvu pa zitsulo sungunuka, slag, ndi zina zowononga TV. Sikuti oxidize kwambiri mumlengalenga pansi pa 400 C, ndipo kuchuluka kwa okosijeni kumawonjezeka kwambiri pa 800 ℃.

Popanda kutulutsa mpweya uliwonse pakatentha kwambiri, imatha kukhala ndi vacuum ya 10-7mmHg pafupifupi 1800°C.

Kugwiritsa ntchito mankhwala

Kusungunula crucible kwa evaporation mu semiconductor makampani.

Mkulu mphamvu zamagetsi chubu chipata.

Burashi yomwe imalumikizana ndi chowongolera magetsi.

Graphite monochromator ya X-ray ndi neutron.

Maonekedwe osiyanasiyana a magawo a graphite ndi zokutira machubu a atomiki.

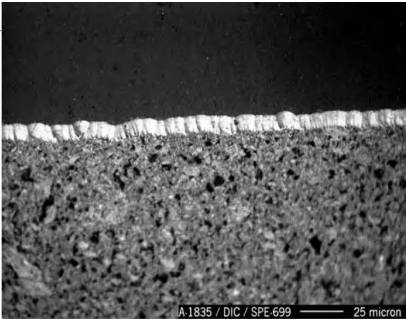

Pyrolytic carbon coating effect pansi pa maikulosikopu ya 500X, yokhala ndi malo osasunthika komanso osindikizidwa.

Kupaka kwa TaC ndi m'badwo watsopano wa zinthu zosagwirizana ndi kutentha kwambiri, zokhazikika bwino kuposa SiC. Monga zokutira zosagwira dzimbiri, zokutira zotsutsa-oxidation ndi zokutira zosamva, zitha kugwiritsidwa ntchito m'malo opitilira 2000C, omwe amagwiritsidwa ntchito kwambiri muzamlengalenga zotentha kwambiri, gawo lachitatu la semiconductor single crystal kukula minda.

| Zakuthupi za zokutira za TaC | |

| Kuchulukana | 14.3 (g/cm3) |

| Kutulutsa kwapadera | 0.3 |

| Kuwonjezela kwamafuta kokwana | 6.3 10/K |

| Kulimba (HK) | 2000 HK |

| Kukaniza | 1x10-5 Ohm *cm |

| Kukhazikika kwamafuta | <2500℃ |

| Kusintha kwa kukula kwa graphite | -10 ~ 20um |

| Kupaka makulidwe | ≥220um mtengo wamba (35um ± 10um) |

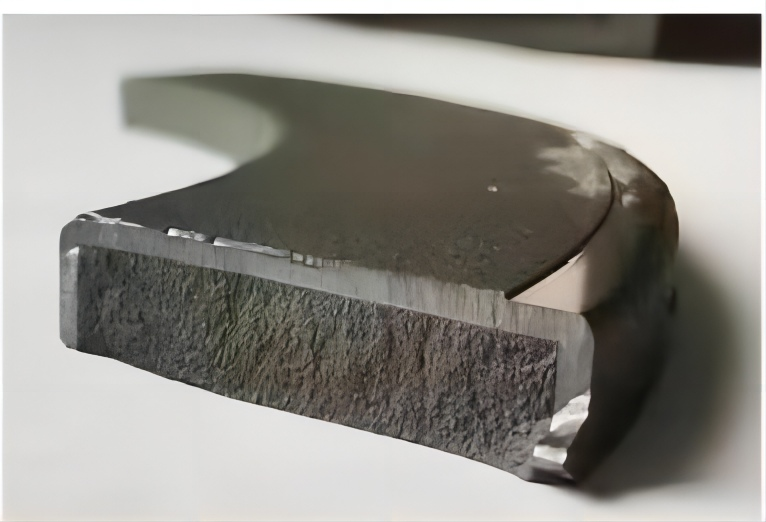

Magawo olimba a CVD SILICON CARBIDE amadziwika ngati kusankha koyambirira kwa mphete za RTP/EPI ndi zoyambira ndi zigawo za plasma etch cavity zomwe zimagwira ntchito pamatenthedwe apamwamba ofunikira (> 1500 ° C), zomwe zimafunikira pachiyero ndizokwera kwambiri (> 99.9995%) ndipo magwiridwe ake ndiabwino makamaka pamene ma resistance tol amakhala okwera kwambiri. Zidazi zilibe magawo achiwiri pamphepete mwa tirigu, kotero zigawo zake zimapanga tinthu tating'onoting'ono kusiyana ndi zipangizo zina. Kuphatikiza apo, zigawozi zimatha kutsukidwa pogwiritsa ntchito HF/HCI yotentha popanda kuwonongeka pang'ono, zomwe zimapangitsa kuti tinthu tating'onoting'ono tizikhala ndi moyo wautali wautumiki.