Silicon carbide (SiC) single crystal chuma ali ndi gulu lalikulu kusiyana m'lifupi (~ Si 3 nthawi), mkulu matenthedwe madutsidwe (~Si 3.3 nthawi kapena GaAs 10 nthawi), mkulu ma elekitironi machulukitsidwe mlingo kusamuka (~Si 2.5 nthawi), mkulu kuwonongeka magetsi munda (~ Si 10 nthawi kapena GaAs 5 nthawi) ndi zina zabwino kwambiri.

Zida za semiconductor za m'badwo wachitatu makamaka zikuphatikizapo SiC, GaN, diamondi, ndi zina zotero, chifukwa kusiyana kwake kwa gulu (Mwachitsanzo) ndi kwakukulu kuposa kapena kofanana ndi ma volts 2.3 amagetsi (eV), omwe amadziwikanso kuti zipangizo zamakono zopangira magetsi. Poyerekeza ndi zida za semiconductor za m'badwo wachitatu ndi wachiwiri, zida za semiconductor za m'badwo wachitatu zili ndi zabwino zaukadaulo wapamwamba wamatenthedwe, malo amagetsi osweka kwambiri, kuchuluka kwakusamuka kwa ma elekitironi apamwamba komanso mphamvu zomangirira, zomwe zimatha kukwaniritsa zofunikira zatsopano zamaukadaulo amakono amagetsi apamwamba. kutentha, mphamvu, kuthamanga, kuthamanga kwafupipafupi ndi kukana kwa radiation ndi zinthu zina zovuta. Ili ndi mwayi wofunikira wogwiritsa ntchito chitetezo cha dziko, ndege, ndege, kufufuza mafuta, kusungirako kuwala, ndi zina zotero, ndipo imatha kuchepetsa kutaya mphamvu ndi 50% m'mafakitale ambiri monga mauthenga a Broadband, mphamvu ya dzuwa, kupanga magalimoto, kuyatsa kwa semiconductor, ndi gridi yanzeru, ndipo kumatha kuchepetsa kuchuluka kwa zida ndi 75%, zomwe ndizofunikira kwambiri pakukula kwa sayansi ndiukadaulo wa anthu.

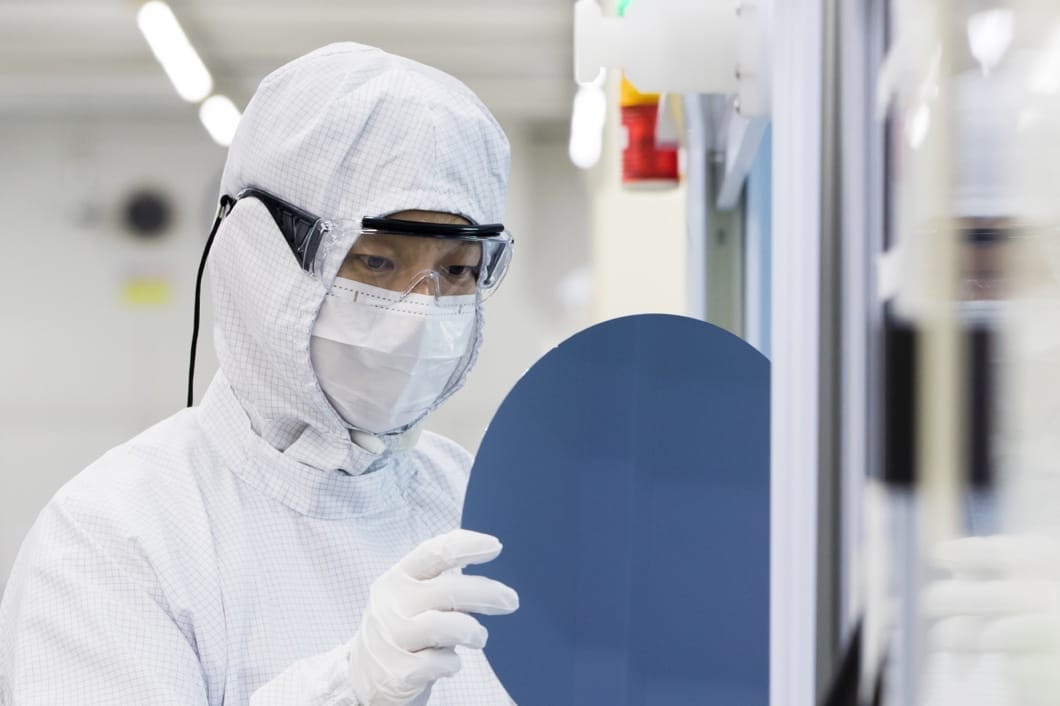

Mphamvu za Semicera zimatha kupereka makasitomala apamwamba kwambiri (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; Komanso, tikhoza kupereka makasitomala ndi homogeneous ndi heterogeneous pakachitsulo carbide epitaxial mapepala; Tikhozanso kusintha pepala la epitaxial malinga ndi zosowa zenizeni za makasitomala, ndipo palibe chiwerengero chochepa cha dongosolo.

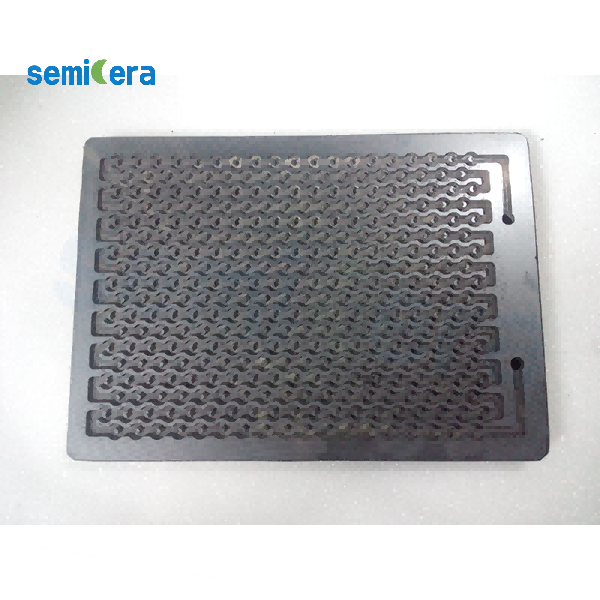

| Zinthu | Kupanga | Kafukufuku | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Kulakwitsa koyang'ana pamwamba | <11-20>4±0.15° | ||

| Magetsi Parameters | |||

| Dopant | n-mtundu wa Nayitrogeni | ||

| Kukaniza | 0.015-0.025ohm · masentimita | ||

| Mechanical Parameters | |||

| Diameter | 150.0 ± 0.2mm | ||

| Makulidwe | 350±25 μm | ||

| Choyambira chapansi pamayendedwe | [1-100] ± 5° | ||

| Kutalika kosalala koyambirira | 47.5 ± 1.5mm | ||

| Sekondale flat | Palibe | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Kugwada | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Front(Si-face) roughness(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Kapangidwe | |||

| Kuchuluka kwa Micropipe | <1 pa/cm2 | <10 pa/cm2 | <15 pa/cm2 |

| Zitsulo zonyansa | ≤5E10 maatomu/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 pa/cm2 | ≤1000 E/cm2 | NA |

| Front Quality | |||

| Patsogolo | Si | ||

| Kumaliza pamwamba | Si-nkhope CMP | ||

| Tinthu ting'onoting'ono | ≤60ea/wafer (kukula ≥0.3μm) | NA | |

| Zikanda | ≤5ea/mm. Kutalika kwake ≤Diameter | Kutalika kokwanira≤2 * Diameter | NA |

| Peel/maenje/madontho/mikwingwirima/ ming'alu/kuipitsidwa | Palibe | NA | |

| M'mphepete tchipisi / indents / fracture / hex mbale | Palibe | ||

| Magawo a polytype | Palibe | Malo owonjezera≤20% | Malo owonjezera ≤30% |

| Chizindikiro cha laser chakutsogolo | Palibe | ||

| Back Quality | |||

| Kumbuyo komaliza | C-nkhope CMP | ||

| Zikanda | ≤5ea/mm, Cumulative kutalika≤2* Diameter | NA | |

| Zowonongeka zam'mbuyo (zolowera m'mphepete / ma indents) | Palibe | ||

| Msana roughness | Ra≤0.2nm (5μm*5μm) | ||

| Chizindikiro cha laser kumbuyo | 1 mm (kuchokera m'mphepete) | ||

| M'mphepete | |||

| M'mphepete | Chamfer | ||

| Kupaka | |||

| Kupaka | Epi-okonzeka ndi zoyika vacuum Kupaka makaseti amitundu yambiri | ||

| *Zindikirani: "NA" zikutanthauza kuti palibe pempho Zinthu zomwe sizinatchulidwe zingatanthauze SEMI-STD. | |||